Among the various material handling options, jib cranes have gained substantial popularity due to their versatility, compact design, and adaptability in diverse industrial scenarios. But how do jib cranes measure up against other common lifting systems, such as overhead cranes, gantry cranes, and hoists?

In this detailed comparison, we’ll explore why jib cranes often provide an optimal solution, discuss their strengths and limitations, and guide you toward informed decision-making for your lifting needs.

To begin, learn How to operate a Jib Crane safelyto maintain an accident-free and productive environment.

Before diving into comparisons, it’s vital to clearly understand what sets jib cranes apart. Essentially, a jib crane consists of a rotating horizontal arm (jib) mounted to a fixed support—typically a vertical column, a wall, or ceiling attachment. This straightforward yet highly effective design allows jib cranes to lift and move heavy loads within a specified radius.

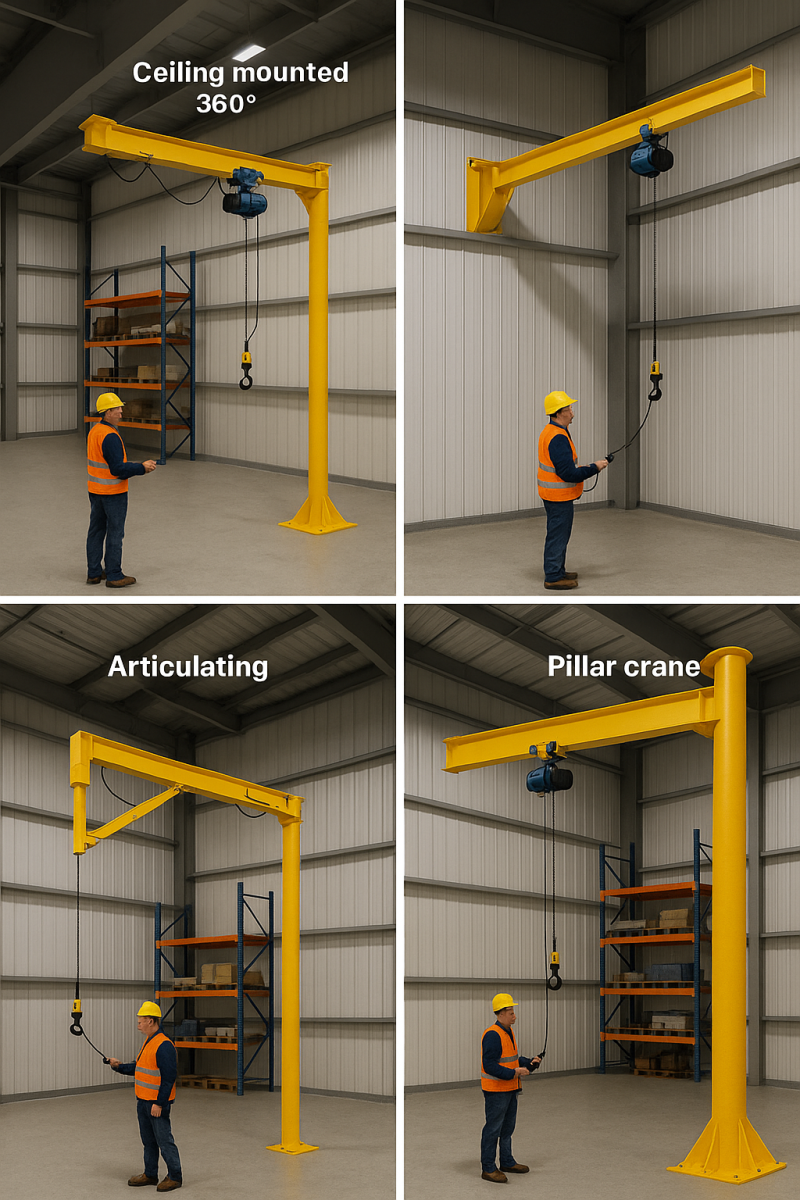

Common types of jib cranes include:

Freestanding jib crane

Wall mounted jib crane

Ceiling mounted jib crane

Articulating jib crane

Pillar jib crane

Each type has unique strengths, suitable for particular settings and requirements. Thanks to their varied configurations, jib cranes offer unmatched flexibility for workplaces where precision, agility, and space optimization are critical.

Overhead cranes typically span an entire workspace and move along fixed rails, suitable for handling extremely heavy and large loads across wider areas. In contrast, jib cranes are stationary but provide excellent localized coverage.

| Criteria | Jib Cranes | Overhead Cranes |

|---|---|---|

| Load Capacity | Moderate (up to ~10 tons) | High (up to 100+ tons) |

| Coverage Area | Localized, targeted area | Large workspace |

| Installation Complexity | Easier and quicker | Extensive, structural |

| Flexibility | High adaptability | Low to medium |

| Cost | Lower initial investment | Higher initial investment |

Thus, overhead cranes may be preferable for extensive, high-capacity operations, while jib cranes excel where agility, moderate capacity, and space efficiency are priorities.

To explore further, read the detailed article: Jib Cranes & Overhead Cranes - Pros, Cons, and Key Differences.

Gantry cranes are movable structures supported by legs with wheels or rails, providing flexible mobility across floor space. While gantry cranes excel in mobility, jib cranes are permanently positioned yet provide excellent lifting accuracy and require minimal floor space.

| Criteria | Jib Cranes | Gantry Cranes |

|---|---|---|

| Mobility | Fixed, rotating pivot | Mobile across workspace |

| Space Required | Minimal space, compact | Requires larger space |

| Lifting Precision | High precision, localized lifting | Less precise, wider lifting |

| Setup Complexity | Easy installation | Moderate to high |

For compact, precise lifting tasks within fixed areas, jib cranes outperform gantry cranes. Conversely, gantry cranes are ideal when portability across wider spaces is essential.

Modern jib cranes are evolving with Industry 4.0, incorporating advanced features and automation technologies that significantly boost efficiency, accuracy, and safety:

Real-time load sensing

Smart monitoring with IoT integration

Automated positioning and precision handling

Predictive maintenance alerts and diagnostics

These intelligent features drastically enhance operational efficiency, safety, and productivity. Explore Smart Technologies in Jib Cranes to see how automation can optimize your lifting tasks.

Jib cranes are remarkably versatile, making them ideal for numerous industries and applications. Typical uses include:

Manufacturing assembly lines

Maintenance workshops

Automotive and aerospace assembly

Warehouse operations

Packaging and loading stations

Discover practical applications by exploring Where is a Jib Crane used for.

Proper selection of a jib crane type ensures safety, efficiency, and cost-effectiveness in your operations. Key selection criteria include:

Load capacity requirements: Determine accurate load handling needs.

Spatial constraints: Consider available space and rotation requirements.

Installation type: Choose between freestanding, wall-mounted, ceiling-mounted, or articulating cranes based on structural feasibility.

Automation needs: Evaluate the level of automation required for your tasks.

Review the available options carefully, considering jib crane selection to match your exact lifting needs.

Accurately calculating load capacity is vital for safe operation and longevity of your jib crane. Key considerations include:

Jib length and load distribution

Structural integrity of support (pillar, wall, ceiling)

Maximum rotational range

Load moment calculations (torque produced by the load at maximum reach)

For a comprehensive methodology, see How to Calculate Load Capacity for Different Jib Crane Types.

One of the unique advantages of jib cranes is their compact footprint. Unlike larger overhead or gantry cranes, jib cranes occupy minimal space, making them ideal for tight, crowded industrial environments. Their compact nature reduces operational congestion, improving productivity and safety.

Understand more about their advantages in the guide: Proper crane selection ensures safe and efficient operations for your facility.

Selecting the right lifting equipment significantly impacts your operational efficiency, safety, and profitability. Jib cranes uniquely combine compactness, agility, and moderate lifting capabilities, positioning them as ideal lifting solutions for various industrial environments.

For precision lifting, confined spaces, or specific workstations, jib cranes offer unparalleled advantages.

Smart technology integration further boosts their efficiency and safety.

Their varied types—freestanding, wall-mounted, ceiling-mounted, articulating, and pillar jib cranes—address nearly every lifting scenario.

In-depth consideration of your specific application ensures you select the optimal lifting solution. For more insights, explore the comprehensive guide:What Makes Jib Cranes a Compact Lifting Solution?.

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.