Is a Jib Crane a Gantry Crane?

This article is designed to provide clarity on the subject by answering common questions like what is a jib crane, exploring the different forms it comes in (for example, jib crane wall mounted and portable jib crane options)

Cranes are an essential part of industrial and construction operations, offering versatile solutions for lifting and transporting heavy loads. Among the various types available, the jib crane and the gantry crane are often compared due to their seemingly overlapping functionalities. However, these cranes differ in design, application, mobility, and installation. In this comprehensive guide, we will explore what a jib crane is, delve into the intricacies of jib crane designs—including jib crane wall mounted and portable jib crane systems—and compare these with gantry cranes to help you understand which system best meets your operational needs.

Introduction

Effective material handling is central to maximizing productivity in industries such as manufacturing, construction, and warehousing. Businesses must choose equipment that not only supports lifting heavy loads but also fits within spatial, budgetary, and operational constraints. The decision often comes down to selecting between a jib crane and a gantry crane. Although both are used for moving heavy objects, they are engineered differently to address unique challenges.

Our discussion is further enriched by exploring related equipment such as material handling equipment and safety accessories like ratchet tie down straps. We will also include reference links to authoritative resources for deeper insights.

Understanding Jib Cranes

What Is a Jib Crane?

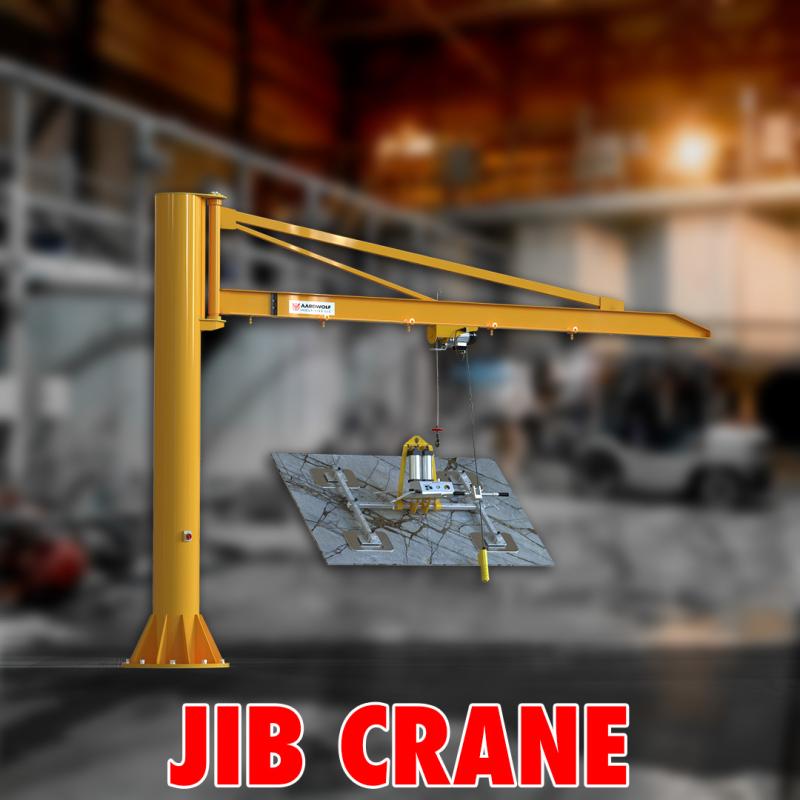

A jib crane is a type of crane that features a horizontal arm (known as the jib or boom) which is attached to a vertical mast or wall. The design allows the crane to rotate around the mast, providing the ability to lift and move loads within a circular area. This compact yet efficient system is often used in workshops, manufacturing floors, and even in outdoor settings where space limitations are a significant factor.

For additional details on the function and features of a jib crane , you can refer to the resource provided by Aardwolf. It outlines the typical components, which include the boom, counterweights, and the motorized hoist system necessary for operation.

Some key advantages of a jib crane include:

-

Space Efficiency: Due to its fixed mounting point, a jib crane occupies minimal floor space while still offering a wide operational area.

-

Versatility: Its rotating mechanism allows it to serve multiple zones in a facility, making it invaluable in environments where efficient space utilization is critical.

-

Ease of Installation: Jib cranes can either be permanently fixed or be designed as portable units for temporary setups.

Variations of Jib Cranes: Jib Crane Wall Mounted and Portable Jib Crane

Jib cranes come in several configurations to meet different operational needs:

Jib Crane Wall Mounted

A jib crane wall mounted system is attached directly to a wall or a support structure. This type is ideal for facilities with limited floor space or where overhead installation is not feasible. The wall-mounted design is common in repair workshops, assembly lines, and maintenance areas where long-term, static installation is preferred.

Wall-mounted jib cranes are particularly beneficial because:

-

They eliminate the need for additional floor space.

-

They provide a permanent solution for frequent lifting requirements.

-

They are often easier to integrate into existing facility infrastructures.

Portable Jib Crane

A portable jib crane offers increased flexibility compared to its wall-mounted counterpart. These cranes can be moved and repositioned according to the needs of the operation. The portable design is well-suited for temporary setups at construction sites, outdoor events, or areas undergoing frequent layout changes.

The advantages of a portable jib crane include:

-

Flexibility in repositioning to adapt to dynamic work environments.

-

Quick installation and dismantling, which is ideal for projects with shifting requirements.

-

Reduced installation costs when a permanent solution is unnecessary.

Exploring Gantry Cranes

What Is a Gantry Crane?

A gantry crane is a type of overhead crane that operates on a track or rails, usually spanning the width of an entire facility or yard. Unlike the jib crane, which rotates around a fixed mast, a gantry crane consists of a bridge that is supported on either side by legs that can be either freestanding or mounted on the ground. This design is especially suitable for large-scale construction sites, shipyards, and industrial plants.

For a detailed explanation and visual comparison, refer to this resource on gantry crane differences. This link explains how gantry cranes differ from overhead cranes, highlighting the particular benefits and applications of each system.

Key characteristics of gantry cranes include:

-

Mobility: Gantry cranes can often move along tracks, making them ideal for covering large work areas.

-

High Lifting Capacity: They are built to handle heavy loads, often more so than jib cranes, making them indispensable in heavy industrial operations.

-

Flexibility in Configuration: Gantry cranes can be designed for indoor or outdoor usage and can be adapted to accommodate various lifting heights and spans.

Comparison: Jib Crane vs. Gantry Crane

When considering the purchase or lease of lifting equipment, understanding the differences between a jib crane and a gantry crane can help in making a more informed decision. Let’s break down the primary distinctions:

Design and Structural Differences

-

Jib Crane:

-

Operates on a pivot mechanism with a fixed mounting point.

-

Typically has a shorter reach compared to gantry cranes.

-

Commonly used where space is limited and overhead structures are impractical.

-

-

Gantry Crane:

-

Features a movable bridge that spans the work area.

-

Offers extensive coverage and higher lifting capacities.

-

Requires more significant installation space and often involves constructing robust support structures.

-

Mobility and Setup

-

Jib Crane:

-

Can be either permanently mounted or designed as a portable system.

-

The portable jib crane variation offers flexibility in repositioning for different tasks.

-

-

Gantry Crane:

-

Is inherently mobile along predefined tracks, making it well-suited for large-scale industrial environments.

-

Its installation is often more complex and may require specialized equipment for setup.

-

Lifting Capacity and Application

-

Jib Crane:

-

Generally used for lighter or moderately heavy loads.

-

Commonly installed in workshop and manufacturing settings where precise and localized movements are required.

-

-

Gantry Crane:

-

Capable of handling significantly heavier loads.

-

Frequently employed in shipyards, container terminals, and large construction projects where the ability to move heavy items over vast distances is crucial.

-

Installation Environment

-

Jib Crane:

-

Fits in confined spaces and is ideal for indoor applications.

-

The jib crane wall mounted system is especially beneficial for facilities with limited floor space.

-

-

Gantry Crane:

-

Requires a substantial footprint and is most effective in open areas.

-

The mobility of a gantry crane along tracks makes it more suitable for environments where large, open spaces are available.

-

Operational Flexibility

-

Jib Crane:

-

Offers more flexibility for localized tasks; its rotating arm allows access to multiple work areas.

-

Beneficial for applications where a fixed point of operation is required.

-

-

Gantry Crane:

-

Designed for broad, heavy-duty industrial applications.

-

Its ability to traverse the entire work area makes it indispensable in large manufacturing floors and distribution centers.

-

Understanding these design and functionality differences is crucial in selecting the right lifting solution for your needs. Although the two systems share a common goal—moving heavy loads—they are optimized for different scenarios, and choosing between them depends largely on the operational environment and specific requirements.

Applications in Material Handling and Industry

Both jib cranes and gantry cranes serve as critical components of modern material handling equipment setups. Their roles extend across various industries:

Manufacturing and Assembly Lines

In manufacturing plants, space is at a premium. A jib crane—especially a jib crane wall mounted variant—can efficiently serve multiple workstations without the need for extensive reconfiguration. Its quick rotation and directional control make it an excellent choice for the assembly, repair, and maintenance of machinery.

Construction and Building Maintenance

Gantry cranes are frequently used in construction sites because of their high lifting capacities and mobility. However, in scenarios where the lifting process is localized—such as installing heavy components within a confined space—a jib crane can provide an effective solution. Moreover, a portable jib crane system may be employed temporarily in areas undergoing renovation or expansion.

Shipping and Logistics

In ports and shipping yards, the robust design of gantry cranes handles large-scale container movements. Nonetheless, within the operational corridors of warehouses and loading docks, a jib crane’s targeted lifting capabilities add significant operational value. The integration of both systems within a single material handling strategy can lead to improved efficiency and safety.

Maintenance and Workshop Environments

Workshops that require frequent repositioning of heavy parts and equipment benefit significantly from the versatility of a jib crane. Whether it is a fixed wall-mounted unit or a portable jib crane, the ability to swiftly rotate and position loads makes it a crucial element in the daily operations of maintenance facilities.

Safety and Operational Considerations

When discussing heavy lifting equipment, safety is paramount. Both jib and gantry cranes must be operated by trained professionals who understand their load capacities and operational limits. One important accessory in ensuring safety during load lifting and transport is the use of ratchet tie down straps. These straps help secure loads during transit, prevent slippage, and reduce the risk of accidents, ensuring that the equipment is used safely and efficiently.

Maintenance and Regular Inspections

Regular inspections and preventative maintenance are essential for the longevity and safe operation of both crane types. Routine checks on the mechanical components, wiring, hydraulic systems, and structural supports are necessary to ensure that any signs of wear or damage are addressed promptly. This proactive approach not only extends the lifespan of the equipment but also protects the workforce from potential accidents.

Operator Training and Certification

It cannot be stressed enough that proper training and certification are critical when operating heavy lifting equipment. Operators need to be well-versed in the manufacturer's guidelines, load limits, and emergency procedures. Investment in comprehensive training programs and continuous education is a key aspect of managing the safety risks associated with crane operations.

Emergency Preparedness

Besides regular maintenance and training, establishing clear emergency protocols is fundamental. This includes having contingency plans for equipment failure, unexpected load shifts, or adverse weather conditions in outdoor installations. Coordinating with onsite safety teams and ensuring all personnel understand the emergency protocols can mitigate risks significantly.

Making the Right Choice for Your Operations

Selecting between a jib crane and a gantry crane hinges on several factors, including available space, load requirements, mobility needs, and the specific industry environment. Here are some steps to guide your decision-making process:

-

Assess Your Operational Space:

Analyze the floor plan and available space. For instance, a jib crane wall mounted system is ideal in compact environments, while a gantry crane is better suited for expansive areas. -

Evaluate the Load Requirements:

Consider the weight and size of the loads. A gantry crane generally offers a higher lifting capacity, but a well-designed jib crane can be perfectly adequate for lighter, yet frequent lifting tasks. -

Determine Mobility Needs:

If your operation involves frequent reconfiguration or temporary setups, consider a portable jib crane system. In contrast, a gantry crane’s mobility is best suited for large, steady workspaces. -

Consider Integration with Existing Systems:

Both types of cranes can complement other material handling equipment. Aligning your choice with existing systems can lead to synergistic improvements in productivity and safety. -

Budget and Installation Costs:

Factor in the installation, maintenance, and operational costs. While gantry cranes may require a higher upfront investment due to structural modifications and space requirements, jib cranes tend to offer more economical solutions for smaller operations.

Conclusion

In summary, while both jib cranes and gantry cranes play invaluable roles within the spectrum of heavy lifting and material handling, they are distinctly engineered for different applications. A jib crane—whether configured as a fixed wall-mounted system or a portable variant—offers a flexible, space-efficient solution for localized tasks. In contrast, a gantry crane is tailored for heavy-duty applications and can cover larger operational areas with its versatile moving bridge system.

Understanding what is a jib crane and how it compares to other crane types, such as the gantry crane, is crucial in making informed decisions that directly impact your operational efficiency and safety. Whether you are seeking to enhance your workshop’s capabilities or looking to manage large-scale construction projects, selecting the right crane type—with proper safety accessories like ratchet tie down straps—ensures smoother operations and a safer work environment.

By weighing the structural features, mobility options, and specific industrial applications of each system, you can determine the most appropriate solution for your heavy lifting needs. Furthermore, integrating these advanced systems with complementary material handling equipment can significantly elevate productivity and operational safety across various sectors.

Ultimately, the decision between a jib crane and a gantry crane should be made based on a thorough analysis of your operational requirements, spatial constraints, and long-term goals. With the right selection and ongoing maintenance, both systems have the potential to transform your material handling processes and provide reliable support for your most demanding industrial tasks.

Embracing the right technology, backed by informed decisions and industry best practices, not only safeguards your operations but also enhances overall efficiency. As industries continue to evolve, staying updated with the latest advancements in lifting equipment will ensure that your business remains competitive and capable of meeting future challenges head-on.

For those interested in exploring more about these systems, refer to the comprehensive resources on jib crane specifics, the distinctions of gantry crane designs, and effective usage of ratchet tie down straps for safe load securing. Additionally, a deeper dive into various forms of material handling equipment can offer further insights into modern solutions for industrial challenges.

With informed decisions and the right equipment, operational efficiency is within reach—and this begins with understanding the core differences between a jib crane and a gantry crane.

Follow us on: