Businesses today seek equipment that combines compactness, versatility, and reliability. Jib Cranes emerge as an ideal solution, offering significant lifting power within a minimal footprint. Whether it’s a small workshop, a high-density warehouse, or a sophisticated assembly line, jib cranes provide tailored lifting solutions without sacrificing space.

This article delves deep into the characteristics that make jib cranes uniquely compact lifting solutions, their distinct advantages, and how they integrate effectively into modern automated environments.

Discover why Jib cranes – a crucial role in your warehouse and material handling strategies.

Jib cranes consist primarily of a vertical support pillar and a horizontal arm (jib) that rotates to cover a specific area. The minimalistic structure inherently conserves space, eliminating the need for extensive floor tracks or complex infrastructure.

Pillar Jib Cranes: Occupy minimal floor space, ideal for workstation lifting.

Wall-mounted Jib Cranes: Attached directly to walls or structural columns, freeing valuable floor space completely.

Ceiling-mounted Jib Cranes: Keep the workspace entirely clear by utilizing overhead structural supports.

Compactness goes beyond dimensions. Jib cranes can be easily integrated into existing infrastructures, making them particularly attractive for upgrades or expansions. The adaptability of these cranes allows businesses to reconfigure workspace layouts dynamically.

Explore more about jib crane specification to determine optimal solutions for your space.

A freestanding jib crane provides 360° rotation around a solid foundation. Its standalone design requires limited floor space and delivers maximum coverage. This type is exceptionally suitable for areas where wall or ceiling attachments aren't feasible.

Ideal applications:

Heavy equipment maintenance areas

Outdoor loading zones

Fabrication and welding stations

Wall-mounted jib cranes offer remarkable compactness by using existing vertical structures. They typically feature rotation ranging between 180° and 200°, ideal for precise, repetitive tasks in confined spaces.

Ideal applications:

Assembly lines

Packing stations

Warehouses with narrow aisles

Ceiling-mounted cranes are an optimal choice in environments where even minimal floor or wall interference can disrupt workflow. These cranes ensure maximum overhead clearance, perfect for facilities with sensitive operations or restricted floor layouts.

Ideal applications:

Cleanrooms and laboratories

Electronics and semiconductor manufacturing

Pharmaceutical processing facilities

An articulating jib crane features a dual-arm design, providing unparalleled maneuverability and flexibility. This allows operators to navigate around obstacles or equipment in tight areas effortlessly.

Ideal applications:

CNC machining centers

Complex assembly cells

Automotive and aerospace assembly lines

Learn more about optimal setups with the detailed jib crane application solutions.

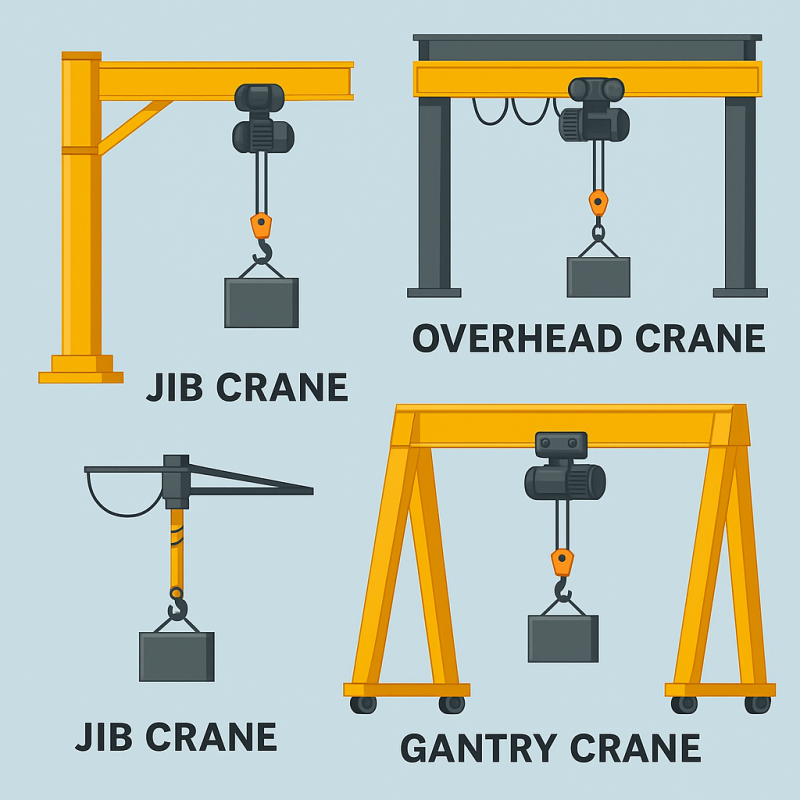

When evaluating lifting solutions, understanding the relative advantages of jib cranes compared to gantry and overhead cranes can guide a more strategic decision-making process.

| Aspect | Jib Cranes | Gantry Cranes | Overhead Cranes |

|---|---|---|---|

| Footprint | Small, targeted lifting | Medium, movable supports | Large, fixed rails |

| Mobility | Stationary rotation, excellent local mobility | Portable, flexible but requires path clearance | Limited to predefined rail pathways |

| Installation Complexity | Low to moderate | Moderate | High |

| Suitability for Automation | Excellent, easy integration | Good, limited automation flexibility | Good, complex infrastructure needed |

Deepen your understanding of these differences in Jib Cranes vs. Gantry & Overhead Cranes: Pros, Cons, and Key Differences.

As industries transition toward automation, jib cranes have also evolved, incorporating smart features that enhance compactness and efficiency.

Smart jib cranes equipped with IoT technology provide data-driven insights for efficient lifting operations, predictive maintenance schedules, and optimized workflows. Automation enhances space utilization by reducing human traffic and errors, further compacting workspace demands.

Explore Automation and Smart Technologies in Jib Cranes for insights into maximizing lifting efficiency.

Automated jib cranes include features such as:

Load and overload sensors

Programmable rotation and positioning

Real-time monitoring and diagnostics

Integrated collision avoidance systems

These features enhance productivity while reducing space requirements and operational disruptions.

Discover more in-depth about Core Smart Features in Automated Jib Cranes.

Facilities worldwide have realized tangible benefits by incorporating compact jib cranes into their lifting solutions.

By strategically placing jib cranes within production zones, companies streamline material handling without interrupting workflow or requiring additional pathways for machinery.

Jib cranes minimize the need for manual lifting, significantly reducing the risk of injury in tight or densely packed environments.

Compact jib cranes easily adapt to changes in facility layout, providing scalability with minimal re-investment or structural changes.

Explore why Cranes – the effective material handling solutions are pivotal in maintaining efficient operations.

Selecting the ideal jib crane involves considering specific operational needs, spatial constraints, and automation goals. Assessing key criteria ensures optimal decision-making:

Task requirements: load capacity, rotation requirements, lift frequency

Environmental constraints: available floor space, ceiling heights, existing infrastructure

Desired level of automation: manual vs. fully automated integration

Make informed choices by Choosing the right jib cranes solution.

Compact, efficient, and versatile, jib cranes significantly enhance productivity and operational safety. From freestanding jib cranes to intelligent articulating jib cranes, each variant offers distinctive benefits tailored to specific industry needs. As industries evolve toward automation, compact jib cranes become even more valuable, seamlessly integrating advanced technologies into streamlined workspaces.

Whether upgrading existing facilities or designing new workflows, investing in jib cranes ensures optimal space utilization without sacrificing performance.

Interested in further optimizing your workspace with jib cranes? Reach out and find the ideal compact lifting solution tailored to your needs.

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.