Among various lifting solutions, Jib Cranes stand out as a practical and highly adaptable choice, especially when equipped with automation features. But how do you determine which type of jib crane is best suited for automation?

This comprehensive guide explains the capabilities of different jib crane types in automation scenarios, their smart features, and how to ensure optimal integration with automated processes.

Learn more about How to operate a Jib Crane safely as safety remains essential even in automated environments.

Automating jib cranes unlocks numerous benefits:

Increased productivity: Automating repetitive tasks boosts workflow speed.

Improved safety: Reduces human error, minimizing risk of accidents.

Enhanced precision: Consistent, repeatable lifting and placement accuracy.

Reduced operational costs: Lowered labor expenses and minimized downtime.

Data-driven insights: Integration with facility-wide systems for predictive maintenance and optimized operations.

To fully realize these benefits, selecting the appropriate jib crane type is critical.

Understanding each jib crane type and its automation potential ensures seamless integration with your facility’s automated workflow.

Freestanding jib cranes offer 360-degree rotation and exceptional versatility, making them highly suitable for automation in manufacturing and logistics environments.

Full rotational coverage allows automated positioning across wide areas.

Easy integration with smart control systems for precise lifting.

Suitable for heavy-duty applications and automated tool changes.

Assembly lines

Machine maintenance stations

Packaging and palletizing stations

Wall mounted jib cranes are permanently installed onto walls or structural columns, optimizing floor space and easily integrating into automated processes.

Limited swing range allows precise programming of pick-and-place operations.

Ideal for automated workstations with restricted operational spaces.

Easy integration with sensors and IoT technologies.

Automated assembly lines

CNC machining centers

Compact warehouses and fulfillment centers

Discover ideal setups and proper jib crane selection for automated environments.

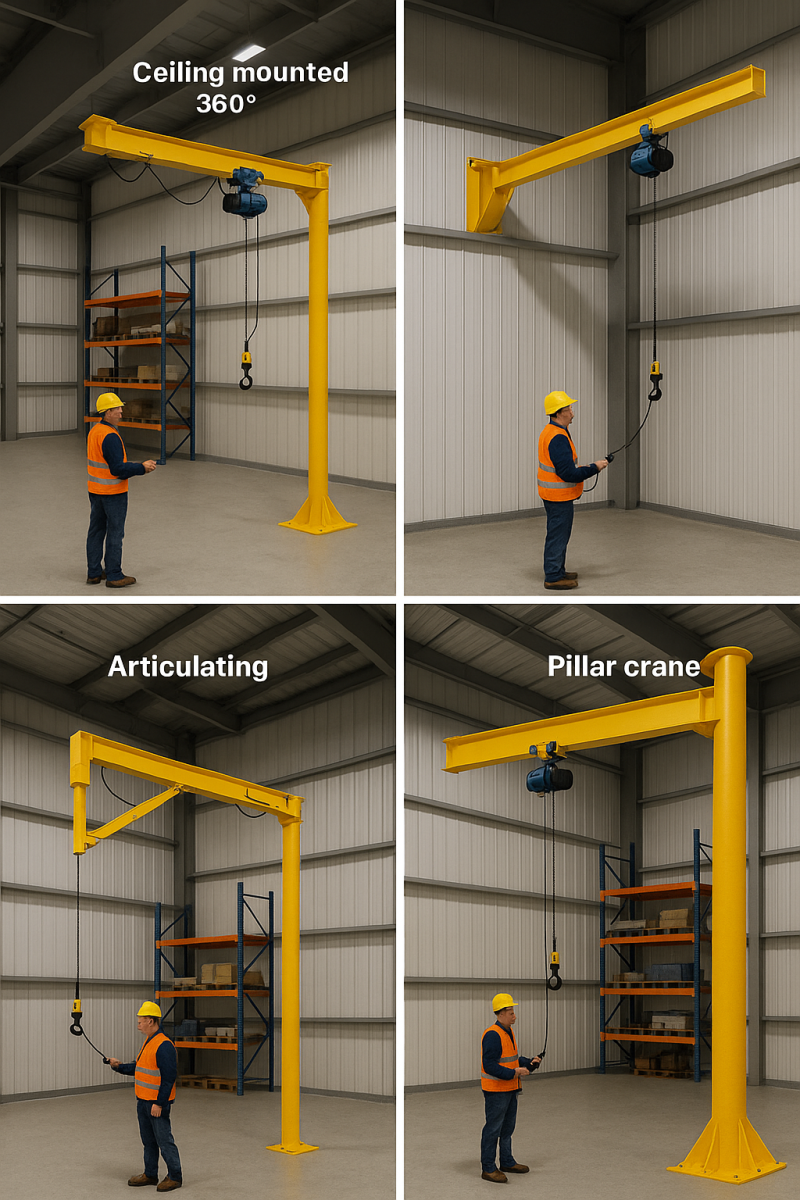

When workspace constraints demand maximum floor clearance, ceiling-mounted jib cranes become the go-to choice. Their design naturally integrates with automation systems, providing overhead lifting with minimal interference.

Unobstructed floor space enhances safety and productivity.

Superior vertical accuracy for delicate, high-precision tasks.

Excellent integration with automated guided vehicles (AGVs) and conveyors.

Cleanrooms (electronics and pharmaceuticals)

Precision assembly areas

High-tech manufacturing facilities

An articulating jib crane features multiple jointed arms, providing exceptional maneuverability around obstacles, ideal for complex automated tasks.

High flexibility and adaptability to intricate automated setups.

Easily navigates tight spaces and avoids interference.

Precise positioning with minimal human intervention.

Automotive assembly plants

Robotics and automated machine loading stations

Aerospace component assembly lines

Learn more about automation-friendly jib crane selection.

Compact and versatile, pillar jib cranes provide a stable, floor-mounted solution for automation scenarios involving consistent, repetitive lifting tasks.

Compact footprint ideal for fixed automated workstations.

Robust structural stability enhances reliability in repetitive automated lifts.

Easy integration with smart monitoring and control systems.

Tool rooms

Automated packing stations

Repetitive lifting and precision placement tasks

Automation in jib cranes is further enhanced by integrating smart technologies, including:

Load sensing and overload protection: Prevents crane overload incidents and increases operational safety.

Programmable movements: Enables precise, repeatable lift sequences.

Remote monitoring and IoT integration: Provides real-time data analytics, predictive maintenance, and proactive fault detection.

Explore in detail the Smart Technologies in Jib Cranes to boost your operational efficiency further.

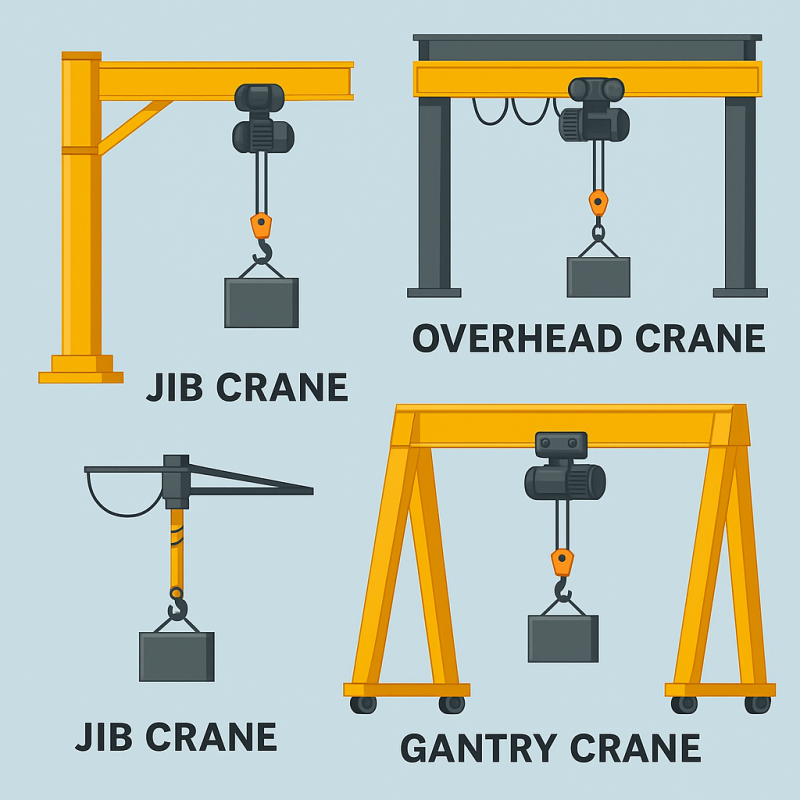

Automating jib cranes provides distinct advantages compared to automated overhead cranes and gantry cranes.

| Features | Jib Cranes | Overhead Cranes |

|---|---|---|

| Automation Integration | Easy and cost-effective | Complex and higher-cost |

| Precision Handling | Excellent precision | Moderate precision |

| Operational Flexibility | High, targeted workspace | Moderate, fixed routes |

| Installation Complexity | Simpler installation | More extensive infrastructure |

Discover deeper insights: Jib Cranes & Overhead Cranes - Pros, Cons, and Key Differences.

Automated jib cranes are essential in a range of industrial applications, including:

Manufacturing facilities with repetitive lifting tasks

Robotic welding and assembly lines

Automated storage and retrieval systems (AS/RS)

Pharmaceutical and semiconductor cleanrooms

For a comprehensive overview, check Where is a Jib Crane used for.

Choosing the right automated jib crane ensures both operational safety and efficiency. Key selection criteria include:

Task-specific requirements: Precision, load capacities, and lifting frequency

Facility layout: Available space, installation structure

Level of automation needed: Smart sensors, programmable lifts, integration with existing automated systems

Remember, Proper crane selection ensure safe and efficient operations for your facility.

Precise calculation of load capacities ensures your automated jib crane performs safely and effectively. Important factors include jib length, structural integrity, and safety factors for automated movements.

Further details: How to Calculate Load Capacity for Different Jib Crane Types.

Choosing the best jib crane type for automation ultimately depends on your specific operational requirements and facility constraints. Automation-ready jib cranes, including freestanding, wall-mounted, ceiling-mounted, articulating, and pillar jib cranes, each offer unique strengths and capabilities.

To further refine your choice, explore our comparison guide: Jib Cranes vs Other Lifting Systems.

Investing in the right automated jib crane type maximizes your facility’s productivity, safety, and long-term profitability.

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.