They are especially critical in workshops, warehouses, and manufacturing facilities where precise load handling is crucial. Understanding how to accurately calculate the load capacity of different jib crane types ensures safe operation, minimizes equipment wear, and enhances productivity.

This comprehensive guide covers the essential methodologies for calculating load capacities for various types of jib cranes—including freestanding jib cranes, wall-mounted jib cranes, ceiling-mounted jib cranes, articulating jib cranes, and pillar jib cranes.

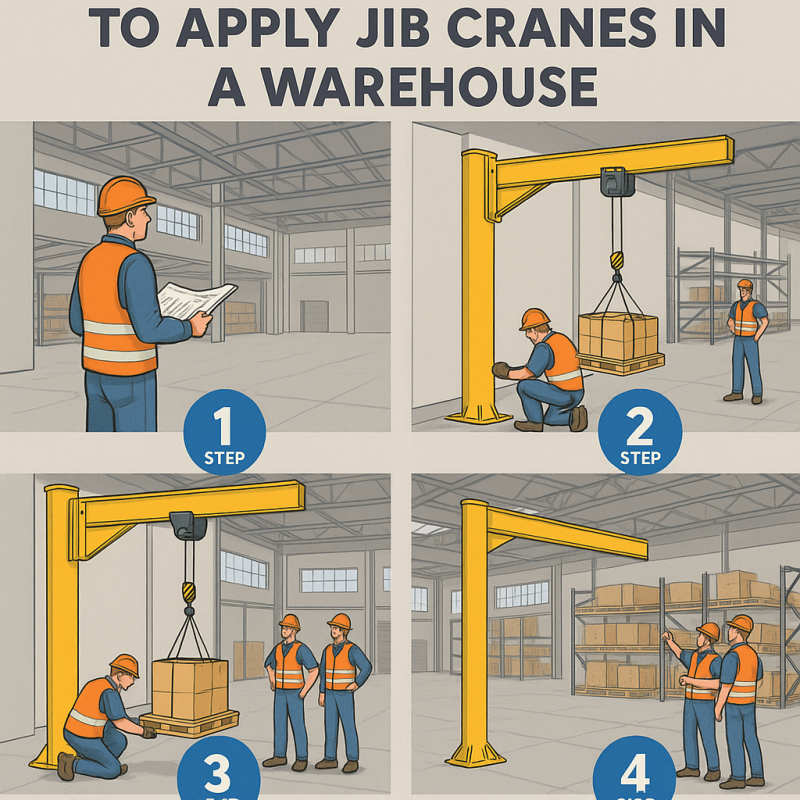

Learn more about why Jib cranes - a crucial role in your warehouse and how properly calculating load capacities can dramatically influence operational efficiency.

Load capacity refers to the maximum weight a crane can safely lift, swing, and lower under optimal operational conditions. This critical factor impacts safety, equipment longevity, and operational efficiency. Improperly calculated or misunderstood capacities can lead to hazardous working conditions and costly downtime.

To ensure optimal safety and performance, it's essential to consider several key elements:

Crane design type

Structural integrity and support mechanisms

Load distribution across the jib

The lifting radius (distance from pivot point to load center)

Environmental conditions and usage frequency

Explore jib crane specification to ensure your equipment meets your facility’s exact lifting needs.

Each jib crane type has unique structural attributes affecting how its load capacity is determined. Let's delve into the calculation specifics for each major jib crane type.

Freestanding jib cranes are anchored to a reinforced concrete foundation, providing full 360-degree rotation. Load calculations primarily depend on:

Height and radius of the jib arm: Increased arm length typically reduces maximum load.

Column size and strength: Heavier loads demand robust columns.

Foundation stability: Concrete thickness, base plate size, and anchor bolts directly impact overall stability.

Calculation Example:

Load Capacity = Structural strength factor × (Jib length ratio) / Applied safety factor

Typical freestanding jib cranes range from 250 kg up to 10 tons capacity.

Wall-mounted jib cranes rely on a solid wall or structural column, usually rotating around 180–200 degrees. Key load determinants include:

Wall or column structural integrity

Jib length and mounting height

Load moment (torque produced by the load at full extension)

The load moment calculation:

Load Moment = Load (kg) × Distance from pivot (m)

Wall-mounted jib cranes typically handle loads from 100 kg to 5 tons, depending on installation quality and support structure.

Check why these cranes are ideal as Cranes – the effective material handling solutions.

Ceiling-mounted jib cranes are attached overhead, significantly influencing their load capacity through:

Ceiling structural strength

Vertical drop and arm length

Swing radius limitation and stability of ceiling attachments

Due to their unique overhead installation, these cranes often handle lighter capacities—generally 50 kg to 2 tons, focusing on precision lifting in clean environments.

Articulating jib cranes have segmented arms with hinge points, offering greater maneuverability but typically lower maximum capacities due to structural complexity.

Critical factors include:

Multiple pivot points and joint stability

Arm segment lengths and their combined load moment

Reinforcement at hinge points

Articulating jib cranes generally handle loads from 100 kg up to about 2 tons. Their strength lies in complex handling rather than heavy lifting.

Learn more with this detailed jib crane application.

Also known as pillar jib cranes, these are compact floor-mounted units ideal for repetitive lifts in confined spaces.

Load calculation parameters:

Pillar diameter and thickness

Foundation quality

Arm length and swing range

Pillar jib cranes typically range between 250 kg and 5 tons, with moderate to heavy-duty options available for special applications.

The accuracy of load capacity greatly depends on the crane’s structural quality and installation integrity. Properly secured anchors, correctly installed brackets, and verified structural supports ensure maximum operational capacity.

Environmental conditions such as wind, humidity, and extreme temperatures can significantly impact crane performance and load ratings.

Regular maintenance and inspections help maintain a crane’s stated load capacity, preserving safe and effective operations.

When choosing a crane, understanding load capacity differences between jib cranes and other crane types like overhead and gantry cranes is essential.

| Feature | Jib Cranes | Gantry Cranes | Overhead Cranes |

|---|---|---|---|

| Max Capacity | Moderate (up to ~10 tons) | Moderate to Heavy | Heavy (up to 100+ tons) |

| Installation Cost | Lower | Moderate | Higher |

| Flexibility | High | Moderate | Low |

| Automation Ease | Excellent | Good | Moderate |

Get more insights from the comparison guide: Jib Cranes vs. Gantry & Overhead Cranes: Pros, Cons, and Key Differences.

Today’s advanced jib cranes feature automation and smart technologies to precisely monitor and optimize load capacity.

Real-time sensors continuously measure weight and torque

IoT-enabled cranes send load data to facility management systems

Automated safety shut-offs prevent overload conditions

Explore further the role of Automation and Smart Technologies in Jib Cranes in ensuring safe and efficient operations.

Calculating accurate load capacities for jib cranes is critical for ensuring workplace safety, optimizing crane performance, and maximizing productivity. Whether utilizing a compact wall-mounted solution or a robust freestanding jib crane, understanding and adhering to these calculations protects both personnel and investments.

To better understand compact designs and their operational advantages, read: What Makes Jib Cranes a Compact Lifting Solution?.

Considering upgrading or investing in jib cranes? Accurate load capacity calculations combined with proper crane selection ensure long-term, safe, and efficient operations for your facility.

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.