Jib Cranes, once considered simple lifting devices, have transformed into intelligent, integrated systems that play an essential role in streamlining operations. Whether you operate a manufacturing plant, logistics center, or maintenance workshop, investing in smart jib cranes can deliver substantial returns.

This article explores the strategic benefits of modern jib cranes, covering types, use cases, and why upgrading to intelligent systems is a future-proof move.

Discover how Jib cranes play an crucial role in your warehouse and how smart technology turns them into a high-value asset.

Smart jib cranes are more than just mechanical arms. They incorporate:

Automation (motorized rotation and hoists)

Sensors (load detection, collision avoidance)

Data connectivity (real-time diagnostics, WMS integration)

AI and machine learning (predictive maintenance, intelligent routing)

These features allow smart cranes to operate with precision, reduce human error, and integrate with other automated systems.

Learn more about How jib cranes work efficiently and adapt to modern workflows.

Traditional overhead cranes and gantry cranes still serve large-scale needs. However, smart jib cranes offer key advantages in localized operations, including:

| Feature | Jib Cranes | Overhead Cranes |

|---|---|---|

| Space Efficiency | High | Medium |

| Installation Cost | Low to Medium | High |

| Flexibility | Excellent | Limited |

| Automation Integration | Seamless | Complex |

| Best Use Case | Workstation lifting | Facility-wide lifting |

Explore What is the difference between jib cranes vs overhead cranes for deeper comparison.

Each type of jib crane offers unique structural and operational advantages. Choosing the right one depends on the specific task and environment.

Installed on a reinforced concrete base, these offer 360° rotation and are ideal for heavy lifting zones. Smart enhancements may include motion control, load balancing, and anti-collision systems.

Perfect for tight spaces, wall-mounted cranes swing 180° and attach directly to walls or building columns. Their smart features include programmable swing limits, smart hoist stops, and speed variation.

Ideal for cleanrooms or assembly lines where floor space is precious, ceiling-mounted systems eliminate obstructions. They integrate with conveyor systems and warehouse software.

These have a jointed arm and excel at navigating around corners or obstructions. They're excellent for machine loading zones, offering high flexibility with smart motorized articulation.

Discover Selecting jib cranes solution to see real-world applications of smart articulating cranes.

Compact and workstation-friendly, pillar cranes are best for maintenance tasks and small tool handling. Automation boosts productivity by minimizing manual input.

Smart sensors monitor load weights and environmental variables, triggering emergency stops when thresholds are exceeded. This significantly reduces workplace incidents.

By automating repetitive tasks and reducing human input, companies can handle more work with fewer delays—boosting throughput in warehouses and workshops alike.

Smart cranes feature predictive maintenance, warning operators before issues become breakdowns. This minimizes unplanned downtime and reduces repair costs.

Modern jib cranes sync with ERP and WMS platforms, enabling real-time inventory tracking, optimized lift cycles, and seamless order fulfillment.

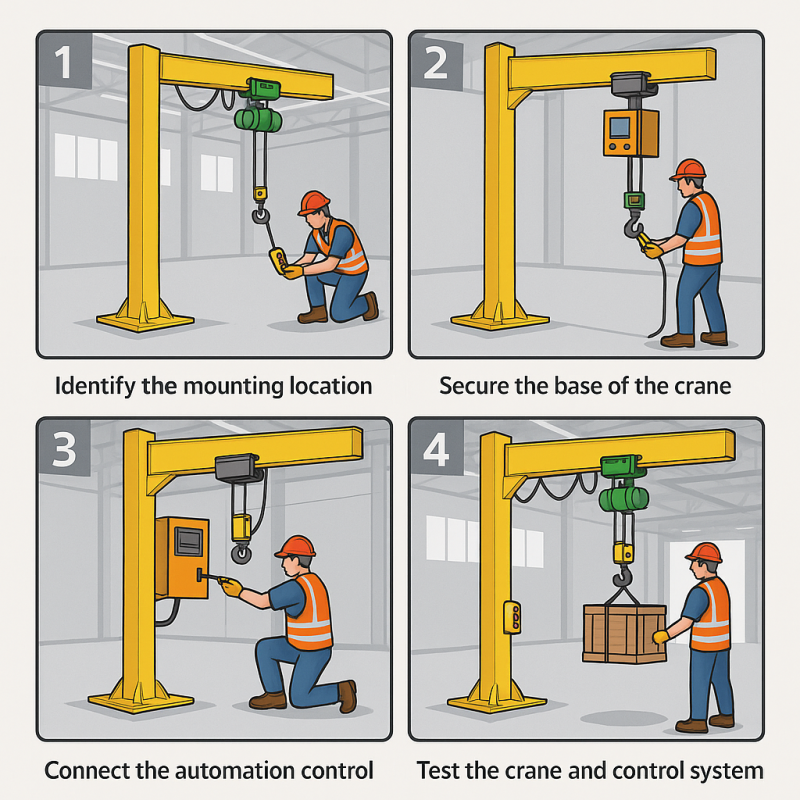

For installation and configuration guidance, read How to choose the right crane is just the first step.

Companies across industries are seeing impressive returns from smart crane investment:

Aerospace Assembly: Using smart ceiling-mounted jib cranes for precision part placement reduced handling time by 30%.

Metal Fabrication: Freestanding jib cranes with AI-driven lift cycles improved worker safety and efficiency.

E-Commerce Fulfillment: Wall-mounted jib cranes improved order packing speeds by 25% with programmable hoists.

See more Use Case Examples in Smart Industrial Environments.

Smart jib cranes consume less energy thanks to optimized motor usage and intelligent idle modes. Compared to overhead cranes, which often run continuously across large areas, smart jibs only activate as needed.

This efficiency supports ESG initiatives and reduces operational carbon footprints—especially when deployed across multiple workstations.

When deciding which smart jib crane to invest in, consider:

Load requirements (capacity, frequency)

Workspace constraints (height, rotation limits)

Integration needs (existing systems, sensors, WMS)

Installation environment (indoor/outdoor, cleanroom, high-traffic)

Explore compact and scalable options like Jib cranes – the effective lifting solutions for specific use cases.

As IoT and AI continue to evolve, jib cranes will offer even more advanced capabilities:

Voice-activated lift control

Augmented reality diagnostics

Fleet-level performance dashboards

Predictive lifecycle management

Read about The Future: AI and Smart Learning in Jib Cranes for what's coming next.

Smart Jib Cranes are no longer luxury equipment—they’re strategic assets that improve operational agility, workplace safety, and long-term ROI. Whether you’re looking to automate a single workstation or scale intelligent lifting across your facility, smart jib cranes offer the ideal balance of innovation and performance.

By selecting the right crane type and smart features, you position your business to meet the demands of tomorrow—today.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.