Among the many technologies contributing to this transformation, Jib Cranes stand out as a cornerstone of efficiency in modern material handling. Their ability to adapt to different spatial layouts and tasks makes them essential tools in smart factories, logistics hubs, and manufacturing lines.

This article explores real-world applications of Jib Cranes in smart industrial environments—highlighting the unique advantages of each type and showcasing how they support intelligent workflows and safety standards.

Discover why Jib cranes play a crucial role in your warehouse, especially when integrated with Industry 4.0 technologies.

Before diving into specific applications, it’s important to grasp what makes Jib Cranes so valuable. Compact, customizable, and efficient, they offer a wide range of motion and lifting capacity, even in tight or specialized environments.

Modern smart facilities employ sensors, automated controls, and AI-powered systems. Jib cranes fit perfectly into this ecosystem, offering:

Real-time load monitoring

Programmable lift limits

Intelligent collision avoidance

Integration with warehouse management systems (WMS)

Learn more about How jib cranes work efficiently and how different configurations adapt to varying industrial needs.

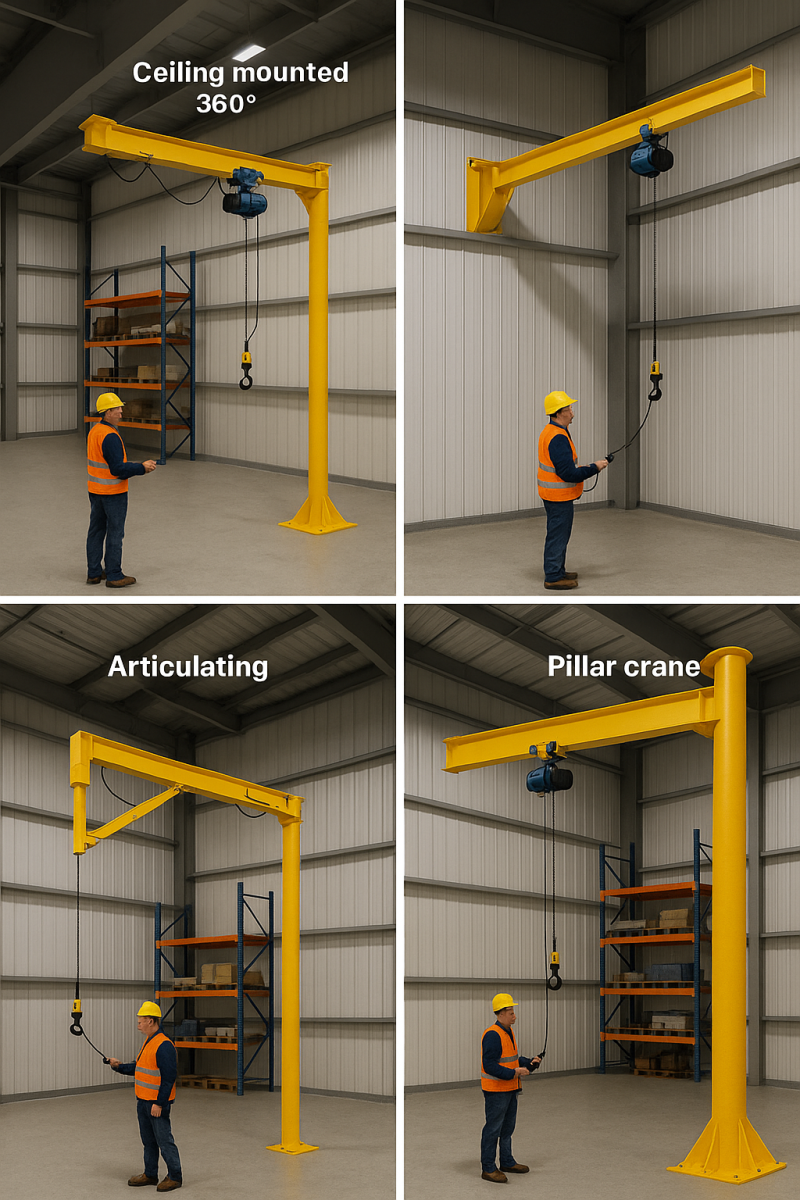

A freestanding jib crane provides 360-degree rotation and is anchored into a reinforced foundation. In automotive assembly lines, they’re commonly used for lifting engines, transmissions, or body panels into place.

Full range of motion without interfering with other equipment

Load capacities up to several tons

Compatible with smart hoists and programmable lifting sequences

For example, a Tier 1 automotive supplier in Germany uses freestanding jib cranes equipped with AI-based hoist controllers to automate repeated lifting of engine blocks with zero deviation.

Wall mounted jib cranes are a smart choice for facilities with limited floor space. These are bolted to building columns or walls, offering up to 200° rotation and seamless integration into production lines.

Box and pallet handling in FMCG packaging

Mounting to existing infrastructure

Enhanced productivity with minimal footprint

A Malaysian packaging company implemented wall-mounted jib cranes with load limiters and push-button control. The system reduced human error and enhanced lifting speed by 35%.

Explore options for Jib cranes – the effective lifting solutions.

Ceiling mounted jib cranes eliminate floor obstruction and are ideal for electronics or pharmaceutical sectors where space is critical and cleanliness is essential.

Synchronization with conveyor belts

Programmable clean-zone lifting routes

Remote diagnostics and predictive maintenance

Their clean design and ceiling attachment enable the movement of sensitive items like semiconductor wafers without the risk of ground-level contamination.

Articulating jib cranes feature a dual-arm setup for navigating tight spaces and complex layouts. These are often installed near CNC machines for loading and unloading parts.

Obstacle avoidance through jointed articulation

Adaptive hoist behavior with load sensors

Integration with robot-assisted production cells

At a precision parts factory in South Korea, articulating jib cranes helped reduce CNC idle time by 40% by enabling efficient side-access loading.

Learn more about Selecting jib cranes solution for manufacturing environments.

Pillar jib cranes are compact, floor-mounted units ideal for repetitive, low-capacity lifting tasks in labs or tool maintenance rooms.

Lifting motors for repair

Mounting test equipment

Repetitive workstation lifting

Equipped with motion sensors and auto-stop features, smart-enabled pillar cranes reduce strain injuries while maintaining workflow efficiency.

While both crane types serve lifting needs, jib cranes offer flexibility, lower installation cost, and integration with workstation-level automation. Overhead cranes span entire bays and are ideal for heavy, bulk lifting.

| Criteria | Jib Cranes | Overhead Cranes |

|---|---|---|

| Space efficiency | High | Medium |

| Automation support | Strong | Advanced |

| Installation cost | Low | High |

| Use case | Targeted lifting | Whole-facility lifting |

Find a detailed guide on What is the difference between jib cranes vs overhead cranes for smart deployments.

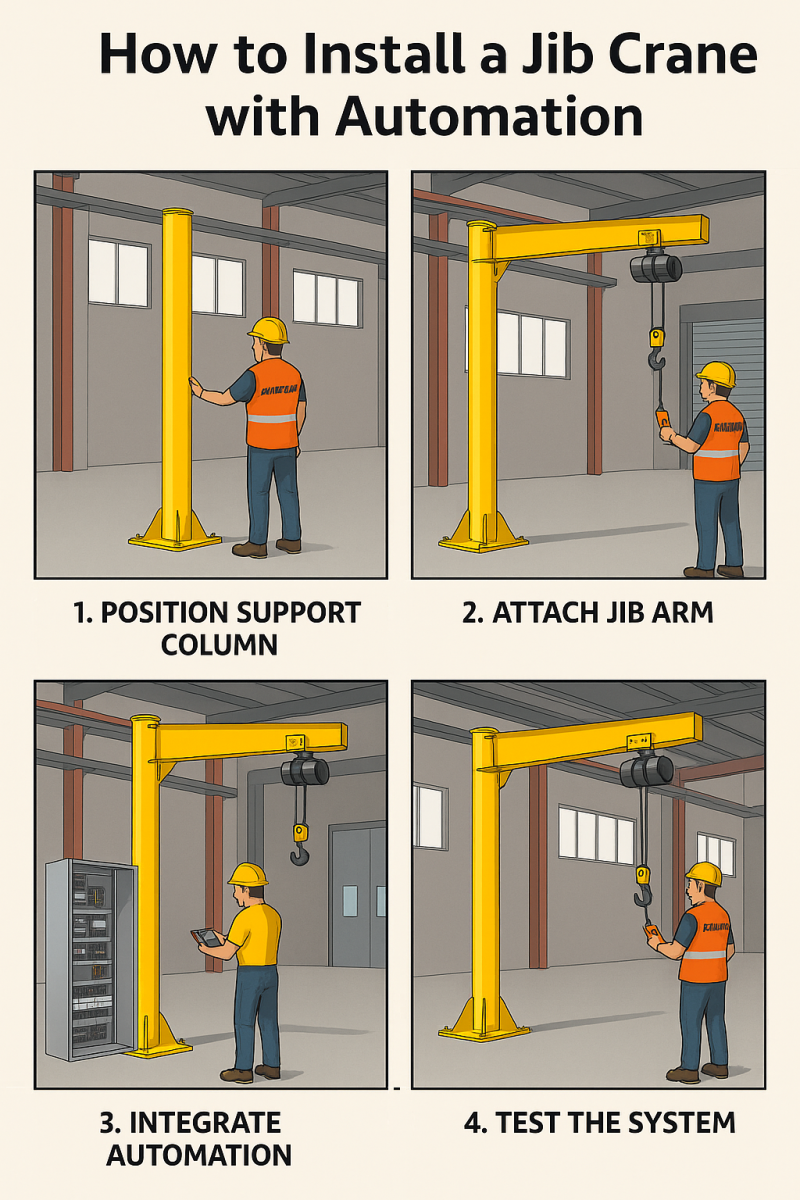

If you're upgrading or setting up your facility, selecting the right type of jib crane is only part of the process.

Analyze lifting frequency and weight range

Evaluate spatial constraints and workflow layout

Choose appropriate crane type (freestanding, wall-mounted, etc.)

Select smart features: sensors, programmable controls, or remote operation

Train staff and perform test cycles

For more, review How to choose the right crane is just the first step.

Smart environments demand learning systems. AI-powered jib cranes will soon adapt based on operator behavior, job frequency, and dynamic workspace analytics.

Predictive maintenance alerts

Real-time optimization suggestions

Voice control for hoists

IoT-based performance dashboards

See what’s coming in The Future: AI and Smart Learning in Jib Cranes.

Jib cranes aren’t just lifting devices—they’re intelligent collaborators in smart industrial environments. Whether it’s a freestanding jib crane in automotive assembly or an articulating jib crane beside CNC machines, the integration of automation and AI makes them future-proof assets.

As more industries digitize operations, the demand for precise, efficient, and connected lifting systems will only grow. Jib Cranes provide the balance of simplicity and intelligence that today’s facilities need.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.