As factories and warehouses adopt advanced technology, lifting equipment like Jib Cranes are also undergoing a transformation. Integrating Artificial Intelligence (AI) and machine learning into material handling tools allows businesses to unlock new levels of productivity, safety, and adaptability.

This article explores how smart technology and AI are reshaping the future of jib cranes, the benefits of intelligent lifting systems, and the role different crane types play in this evolution.

Let’s dive into how Jib cranes play an important key in your warehouse when equipped with intelligent technology.

A smart jib crane combines traditional mechanical lifting with digital intelligence. These systems use sensors, processors, and machine learning algorithms to monitor operations, predict maintenance, and optimize lift cycles.

AI-based path optimization for load movement

Automated collision detection and avoidance

Load weight sensing and dynamic adjustment

Real-time performance monitoring and predictive maintenance

Integration with warehouse management systems (WMS)

As industries evolve, How jib cranes work in industries now includes smart learning, making them capable of adapting to operator behavior and environmental conditions.

AI in jib cranes is about more than automation—it’s about adaptability. A crane equipped with AI can analyze lifting patterns, improve efficiency based on historical data, and reduce human error through self-regulation.

Here’s how AI benefits jib cranes:

Machine learning algorithms detect wear patterns and signal early when maintenance is due, minimizing downtime and avoiding costly failures.

Smart cranes dynamically adjust speed and movement based on load weight and center of gravity, enhancing safety and precision.

AI systems can “learn” from frequent tasks. Over time, cranes begin to automate recurring patterns, reducing the time required for manual control.

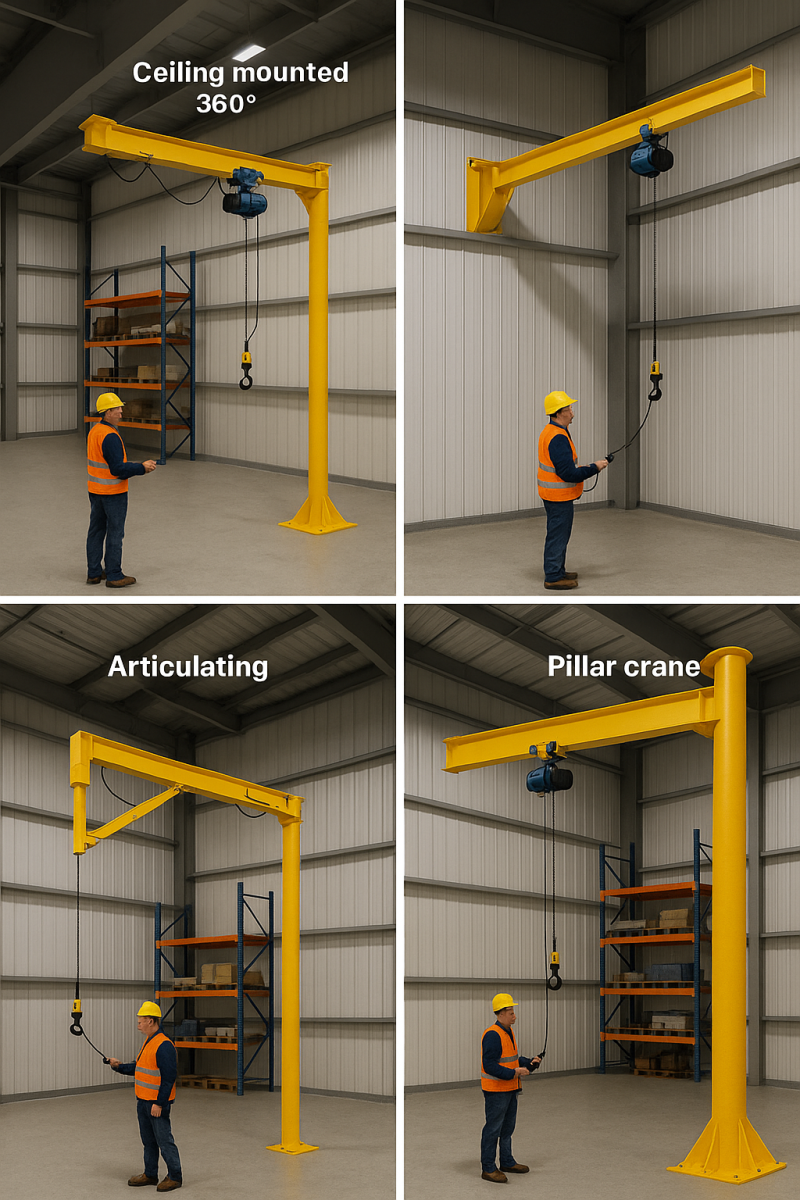

Each type of jib crane offers unique opportunities for smart feature integration. Understanding the capabilities of each helps in selecting the ideal setup for AI advancement.

Ideal for 360° AI-assisted rotation

Supports full automation and smart hoist integration

Great for high-load industrial environments

Seamlessly integrates with automated workstations

Smart sensors detect obstacles and limit swing paths

Perfect for space-constrained setups with repetitive tasks

AI can coordinate ceiling cranes with AGVs or conveyors

Load-sharing capabilities with adjacent systems

Works well in clean environments like electronics or pharma

Smart articulation allows for precise, adaptive pathing

Advanced motion control for navigating complex machinery layouts

Excellent for delicate or varied lifting needs

Enhanced for repetitive, high-frequency tasks

AI-assisted lift profiles boost throughput in maintenance shops

To understand smart upgrades, visit How Smart Features Vary by Jib Crane Types.

How do jib cranes stack up against larger systems like overhead cranes when AI enters the equation?

| Feature | Jib Cranes | Overhead Cranes |

|---|---|---|

| Space Efficiency | High | Moderate |

| Installation Cost | Lower | High |

| Automation Potential | Strong | Very High |

| Ideal Use Case | Workstation or Zone Lifting | Facility-Wide Lifting |

| Flexibility | High | Medium |

For a closer look, see this Jib cranes vs overhead cranes comparison.

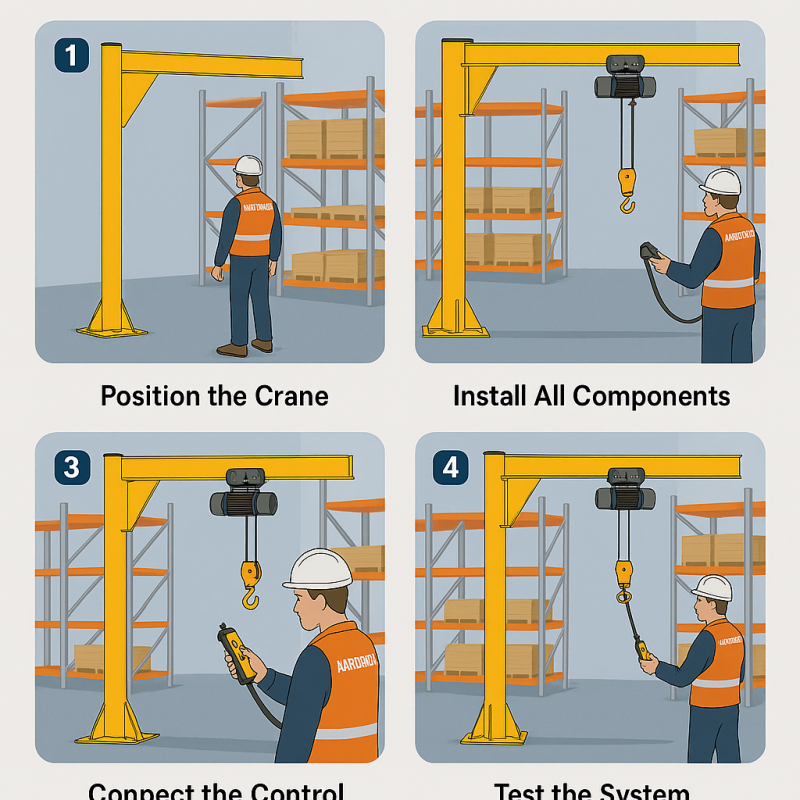

Implementing smart crane systems isn't just about buying new hardware—it's about integrating intelligence into existing workflows.

Identify load types, workflows, space restrictions, and current manual operations.

Use this guide: How to select the right crane is just the first step

Install motorized rotation, load sensors, and IoT modules.

Link cranes to warehouse software for seamless task automation.

A packaging plant adopted a jib cranes - compact lifting solution for robotic carton handling. By integrating load sensors and programmable lift cycles, they reduced manual lifting by 60% and improved packing speed by 40%.

AI helped optimize lifting height per box size, preventing product damage and improving worker safety.

Not every company needs the same level of intelligence. Here’s a quick breakdown to help:

| Use Case | Recommended Crane | Smart Features |

|---|---|---|

| Repetitive bench-level lifts | Pillar Jib Crane | Lift counters, speed controls |

| Narrow workstations | Wall Mounted Jib | Obstacle sensors, motion presets |

| Large production zones | Freestanding Jib | Load balancing, predictive rotation |

| Complex machinery zones | Articulating Jib | Path optimization, smart articulation |

Ready to Select jib cranes solution that aligns with your smart warehouse?

What’s on the horizon?

Voice-activated controls

Cloud-based performance dashboards

Automated safety check routines

AI-driven layout suggestions for crane optimization

These developments signal a future where cranes not only lift but also think and respond.

AI-powered Jib Cranes are not just a trend—they’re a vital tool in the modern, connected factory. Whether you’re upgrading to motorized control or implementing full intelligent automation, the benefits in safety, speed, and precision are undeniable.

From Jib cranes play an important key in your warehouse to advanced robotics integration, these systems adapt with your growth.

Would you like this content adapted for your product brochure, comparison landing page, or presentation slide deck? Let me know—I’d be happy to help tailor it.

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.