Among the most versatile material-handling tools available, Jib Cranes continue to adapt and thrive. Known for their space efficiency and flexibility, these cranes are now being enhanced with intelligent features tailored to specific environments and crane types.

From load monitoring to programmable lift cycles, smart features are changing how businesses interact with their cranes—boosting productivity, safety, and long-term value.

Let’s dive into how modern smart capabilities vary by jib crane type and which setup suits your workflow best. Discover why Jib cranes play an important key in your warehouse and how the right features make all the difference.

Traditionally, jib cranes were operated manually or with basic electric hoists. However, today's models are available with enhancements that include:

Motorized rotation and trolley travel

Digital load displays and sensors

Programmable motion control

IoT connectivity and real-time diagnostics

Remote operation and safety automation

These technologies support greater lifting precision, safer operation, and integration with factory management systems.

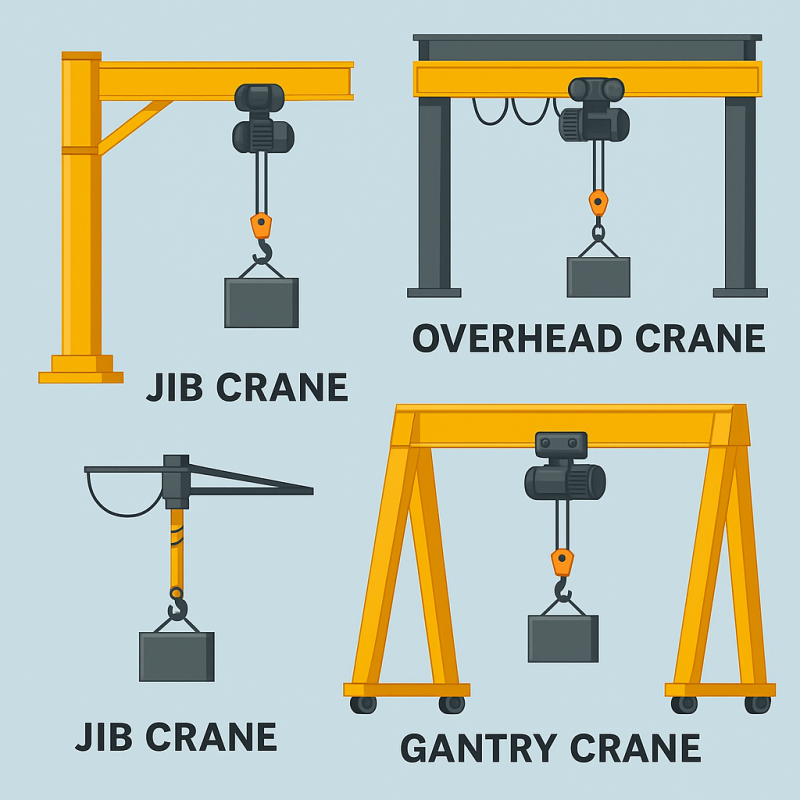

To choose the right automation level, you must first understand the types of jib cranes available. Here’s how How jib cranes work in industries influences the kinds of smart tools they can support.

A freestanding jib crane is mounted on a concrete foundation and operates independently from the building’s structure. With its 360-degree rotation and ability to support heavier loads, this type is perfect for heavy-duty smart lifting features.

Common Smart Features:

Servo-controlled motorized slew

Load-sensing hoists with data logging

Auto-lift cycle presets for repeated tasks

Anti-collision zones and path monitoring

Use Case: A metal fabrication facility uses freestanding jib cranes with programmable height limits and wireless remotes to speed up repetitive part loading.

A wall mounted jib crane is bolted to a structural wall or column and swings across a semicircular path, typically 180° or 200°. It’s ideal for workstations where floor space is tight, such as packaging lines or maintenance zones.

Smart Add-ons:

Variable-speed electric hoists

Load readout displays for small-batch handling

Limit switches and restricted zones for safety

Touchpad or push-button control panels

For tailored workspace installations, select jib cranes solution with motorized swing and programmable lift positions.

By being attached to overhead trusses or beams, ceiling mounted jib cranes save floor space and keep the workspace clear. They’re commonly used in cleanroom environments, assembly lines, and high-density storage facilities.

Smart Capabilities:

Programmable lift/lower speeds for fragile goods

Integration with AGVs or conveyor systems

RFID-based safety interlocks

Remote diagnostics via cloud dashboard

Compact and clean, jib cranes - compact lifting solution deliver optimal function in space-constrained zones.

Featuring a two-part arm for increased reach and maneuverability, articulating jib cranes are the smartest of the bunch. They can lift around obstacles, tight corners, and within machinery clusters.

Key Smart Features:

Jointed motor control for flexible arm movement

Obstruction detection and rerouting

Smart zones for autonomous operation

Advanced ergonomic controls

Their precision and reach make them ideal for CNC loading, electronics, or pharmaceutical assembly. These are the cranes you upgrade when speed and dexterity are a priority.

Designed for light-duty and repetitive tasks, pillar jib cranes are often mounted on shop floors or benches. They are now also available with semi-automation features that improve consistency and reduce worker fatigue.

Popular Upgrades:

Push-button up/down with speed limits

Smart lift counters for inventory tracking

Auto stop at programmable heights

Visual and audio load indicators

Though smaller, their utility should not be underestimated—especially in environments with high-frequency repetitive movements.

Smart jib cranes provide precision and compactness, but how do they compare with full-scale overhead cranes?

| Feature | Jib Cranes | Overhead Cranes |

|---|---|---|

| Installation Cost | Lower | High |

| Automation Options | Available by type | Highly customizable |

| Floor Footprint | Minimal | Significant |

| Mobility | Stationary | Typically spans large area |

| Use Case | Workstations, targeted lifting | Heavy, bulk movement |

For side-by-side decision-making, review this detailed Jib cranes vs overhead cranes comparison.

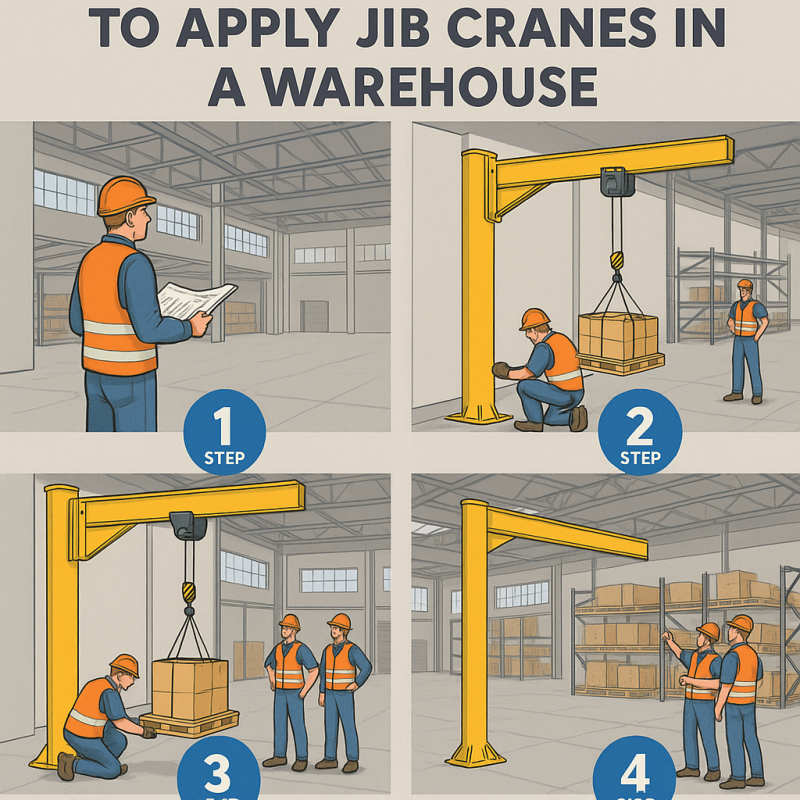

You can’t simply “plug in” automation. Successful smart lifting projects follow a clear roadmap:

Evaluate your current lifting needs

Select the best jib crane type for your environment

(Need help? Read What Are Jib Cranes and Why Are They Vital?)

Choose appropriate smart features

Plan and execute installation

(How to select the right crane is just the first step)

Train staff in proper operation

Monitor and optimize with data insights

The next generation of jib cranes is already shaping up with:

Augmented reality diagnostics

Predictive maintenance via sensors

Integration into MES/ERP platforms

AI-guided lift scheduling

As smart factory trends expand, jib cranes will remain relevant not because they’re simple—but because they’ve adapted to become smarter.

From freestanding to articulating, every type of jib crane has its own potential for smart automation. By understanding your operational needs and the capabilities of each crane type, you can select a lifting solution that supports your current workflow and prepares you for the future.

Ready to make your lift smarter? Start with the right type—and the right tech. Visit Aardwolf to explore cutting-edge solutions for your facility.

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.