Among the most reliable tools in this evolution are Jib Cranes—versatile, compact, and customizable cranes that can now be equipped with smart features to maximize productivity.

In this article, we explore the key types of smart jib cranes, their operational strengths, and why they’re becoming an indispensable part of modern industrial environments.

Discover how Jib cranes play a crucial role in elevating workplace efficiency and automation.

Smart jib cranes integrate automation, sensors, and sometimes AI to transform traditional material handling. When equipped with smart features, jib cranes offer:

Predictive maintenance

Load monitoring and optimization

Integration with warehouse management systems (WMS)

Enhanced operator safety and control

Better energy efficiency

Whether you’re handling light loads at a workstation or rotating heavy machinery into position, there’s a smart jib crane designed for the task.

Learn more about How jib cranes work efficiently in diverse environments.

A freestanding jib crane is mounted to a concrete foundation and can rotate up to 360 degrees. These cranes are ideal for standalone applications where full-range movement is needed.

High load capacity (up to several tons)

Suitable for indoor and outdoor use

Excellent for large work zones

Compatible with smart hoists and electric trolleys

Freestanding cranes are common in shipyards, fabrication shops, and heavy assembly lines.

Wall mounted jib cranes are fixed to existing building columns or walls and usually offer 180° of rotation. They’re the go-to choice for workspaces with limited floor area.

Space-saving design

Easy integration into workstations

Ideal for repetitive, localized tasks

Perfect for light to medium-duty loads

See why Jib cranes – the effective material handling solutions work well in lean facilities.

A ceiling mounted jib crane is attached to overhead support beams. This eliminates floor obstructions entirely, allowing open movement below.

Maximizes usable floor space

Great for cleanrooms or assembly lines

Works seamlessly with AGVs and conveyor systems

Allows high-precision load placement

These cranes are popular in electronics, pharmaceuticals, and aerospace production where cleanliness and efficiency are crucial.

An articulating jib crane features a two-arm design that enables more flexible movement around obstacles and tight corners.

Enhanced range and dexterity

Perfect for complex machine-loading setups

Can maneuver around fixtures and tight layouts

Compatible with advanced automation controls

Explore Choosing the right jib cranes solution for adaptable installations in modern industrial spaces.

Also known as column-mounted jib cranes, pillar jib cranes are compact, stand-alone systems ideal for individual workstations.

Space-efficient and easy to install

Designed for repetitive tasks

Load capacity ranges from light to moderate

A smart option for tool rooms, labs, and maintenance bays

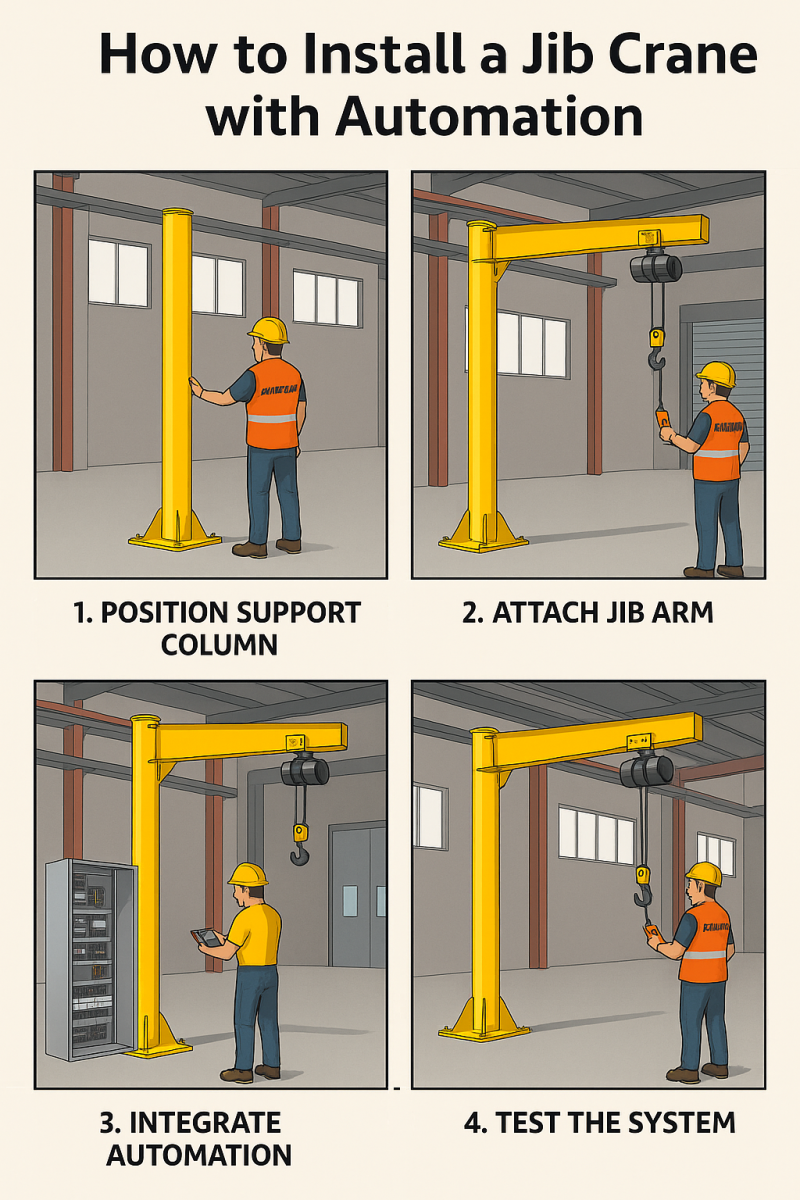

Selecting the right jib crane isn’t just about lifting capacity. It involves understanding the unique spatial constraints, operational goals, and integration needs of your workspace.

Here’s a checklist:

Task type: Machine loading, pallet lifting, assembly

Rotation requirement: 180°, 200°, or 360°

Space availability: Ceiling height, wall proximity

Smart features needed: Load sensors, AI routing, WMS sync

Installation type: Floor-mounted, wall-mounted, or ceiling-suspended

Get step-by-step advice with How to handle the right crane.

Overhead cranes are often used for large-scale, full-facility lifting tasks, while jib cranes shine in workcell-based environments. The difference is not just structural but strategic.

| Feature | Jib Cranes | Overhead Cranes |

|---|---|---|

| Installation Cost | Low to Medium | High |

| Footprint | Small | Large |

| Flexibility | High | Medium |

| Automation Integration | Easier | More Complex |

| Ideal Use Case | Workstations, local zones | Facility-wide transport |

Not sure which suits you? See What is the difference between jib cranes vs overhead cranes.

1. Smart Warehousing

A distribution center in Europe uses smart wall-mounted jib cranes to automate box lifting and sorting, cutting operator workload by 40%.

2. CNC Machine Loading

In a U.S. parts factory, articulating jib cranes load metal blanks onto machines with minimal manual input—speeding up cycle times and reducing accidents.

3. Pharmaceutical Packaging

Ceiling-mounted jib cranes support robotic arms for sterile lifting, working seamlessly in cleanroom environments.

4. Aerospace Component Handling

Freestanding smart jib cranes with 360° motion and programmable hoist settings lift delicate aerospace components safely and accurately.

For more inspiration, explore Advantages of Investing in Smart Jib Cranes.

Investing in the right type of Jib Cranes—especially smart-enabled models—means equipping your operation for greater efficiency, safety, and scalability. Each crane type has its strengths, from space-saving wall mounts to versatile articulating arms.

Smart features further elevate these benefits, making jib cranes essential tools for competitive, forward-thinking facilities.

By evaluating your environment and selecting based on real use cases, your team will not only lift better—but also work smarter.

Need help choosing the right solution? Let’s find the perfect fit for your facility.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.