Central to achieving these goals are reliable and advanced lifting systems. Among them, Jib Cranes have become a vital asset due to their versatility, reliability, and adaptability. With the integration of smart technology, jib cranes—including freestanding jib cranes, wall-mounted jib cranes, ceiling-mounted jib cranes, articulating jib cranes, and pillar jib cranes—have significantly evolved, enhancing their functionality and effectiveness in modern workplaces.

This detailed article explores the key smart features found in contemporary jib cranes, why these advancements are essential, and how businesses can benefit from implementing these sophisticated lifting solutions.

To gain a comprehensive understanding, start by exploring How to choose a Jib Crane.

Traditional jib cranes provided basic lifting capabilities effectively for decades. However, modern demands for precision, efficiency, and safety have ushered in smart innovations that transform jib cranes into highly efficient, intelligent tools.

Smart jib cranes combine traditional structural reliability with cutting-edge technologies, ensuring superior performance across multiple industries, from manufacturing and warehousing to construction and automotive repair.

Modern jib cranes incorporate various advanced technologies designed specifically to improve operational performance, worker safety, and long-term cost efficiency.

Automation in jib cranes allows precise and repeatable lifting and positioning, significantly reducing human error. These systems use computerized controls for seamless crane operation, enabling operators to manage heavy loads effortlessly and safely. Automation ensures smooth and controlled movements, minimizing risks during complex lifting tasks.

Advanced load monitoring technologies provide real-time feedback on load capacities, crane status, and operational safety. Sensors alert operators if load limits are exceeded or if there are potential stability issues. This proactive approach helps prevent accidents and maintain optimal crane efficiency.

Smart jib cranes leverage IoT technologies for enhanced operational management. IoT integration allows real-time data collection and analysis, providing invaluable insights into crane usage patterns, load conditions, and performance metrics. IoT connectivity also enables remote diagnostics and predictive maintenance, reducing downtime and maintenance costs significantly.

Learn more about smart crane types by exploring Types of smart jib cranes.

Predictive maintenance is one of the most transformative features in modern jib cranes. Smart sensors and IoT technology enable real-time condition monitoring, predicting potential failures before they occur. This technology ensures cranes operate optimally with minimal disruption, significantly extending equipment lifespan and reducing unexpected downtime.

Safety features are vital in lifting operations. Modern jib cranes incorporate smart safety mechanisms such as automated collision avoidance, overload protection, and advanced emergency-stop functions. These enhancements help protect workers, prevent accidents, and ensure safe operational conditions, thereby fostering a secure working environment.

Discover more details by reading our comprehensive guide: Understanding the Role of Jib Cranes.

Choosing the right type of jib crane is crucial to fully leverage smart technology advantages. Here are popular jib crane types and their typical applications and benefits:

Freestanding jib cranes are anchored independently to the facility’s floor, offering complete 360-degree rotation. They are ideal for open spaces and large lifting capacities, combining heavy-duty performance with smart features.

Smart Features: Precision automation, IoT connectivity, predictive maintenance.

Ideal Applications: Heavy manufacturing, warehouses, and open assembly areas.

Wall-mounted jib cranes efficiently utilize existing vertical supports, ideal for facilities with limited floor space.

Smart Features: Real-time monitoring, load sensors, automated rotation controls.

Ideal Applications: Small workshops, loading docks, and confined industrial spaces.

Ceiling-mounted jib cranes are mounted overhead, optimizing spatial efficiency, and are ideal in precision manufacturing settings.

Smart Features: Enhanced precision control systems, IoT integration for performance monitoring.

Ideal Applications: Laboratories, cleanrooms, and precision assembly lines.

Articulating jib cranes have multi-jointed arms, providing unmatched flexibility for complex or obstacle-filled environments.

Smart Features: Automated collision detection, precision positioning sensors.

Ideal Applications: Automotive industry, intricate assembly lines, and congested workspaces.

Pillar jib cranes offer stable lifting solutions fixed to robust pillars, ideal for repetitive and heavy-duty tasks.

Smart Features: Load monitoring sensors, predictive maintenance alerts, automated safety features.

Ideal Applications: Heavy machining, fabrication shops, and manufacturing stations.

Explore additional insights by reading about Types of Jib Cranes and Ideal Applications.

Deciding between jib cranes and overhead cranes involves understanding the specific advantages of each:

Space Efficiency: Jib cranes excel in space-limited settings, unlike overhead cranes which need structural reinforcement and extensive space.

Installation Costs: Jib cranes typically require lower initial investment and simpler installation procedures compared to overhead cranes.

Operational Precision: Jib cranes offer precise, localized lifting ideal for specialized tasks, whereas overhead cranes provide broader area coverage.

Make informed decisions by Comparing Jib Cranes vs Overhead Cranes.

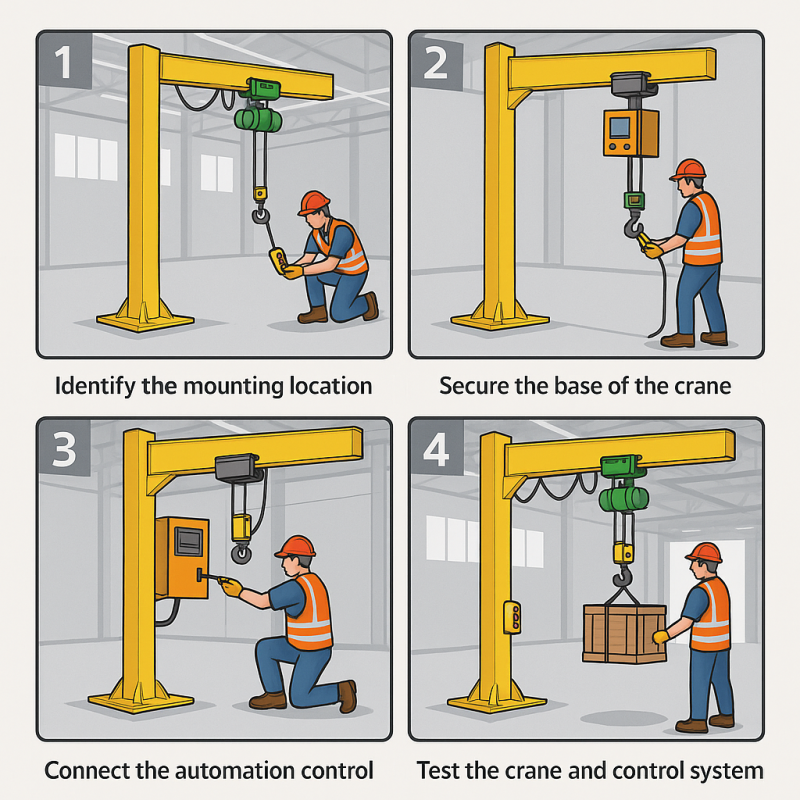

Proper implementation ensures your facility benefits fully from smart jib cranes. Follow these structured steps:

Facility Assessment: Identify operational needs, including load specifications, workflow patterns, and spatial limitations.

Select Crane Type: Choose appropriate crane type based on operational and space considerations.

Smart Feature Integration: Identify essential smart features (automation, IoT, safety mechanisms) for your specific needs.

Installation and Calibration: Follow manufacturer guidelines to ensure accurate setup.

Testing and Training: Thoroughly test cranes and provide comprehensive training for operators to manage smart systems effectively.

Routine Inspection and Maintenance: Regular checks ensure ongoing performance, safety, and compliance.

For a detailed approach, follow our Step-by-step Guide to Smart Jib Crane Implementation.

Careful planning maximizes your return on investment:

Evaluate Long-term Benefits: Enhanced safety, reduced downtime, and improved efficiency.

Future Expansion: Plan for scalable and adaptable solutions to future-proof your operations.

Get started by reviewing our guide on How to Plan for Smart Jib Crane Deployment.

Smart jib cranes offer transformative benefits for industrial operations. Leveraging smart technologies within your lifting equipment boosts productivity, improves safety, and positions your facility to meet evolving industrial challenges effectively.

Explore further about smart crane advantages by reading What Are Smart Jib Cranes?, and start maximizing your facility’s operational capabilities today.

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.