In the evolving landscape of industrial automation and logistics, traditional material-handling equipment has steadily evolved to incorporate advanced technologies. By integrating intelligent technology, these cranes have transformed into smart jib cranes, delivering enhanced productivity, safety, and efficiency.

This article delves deep into what smart jib cranes are, highlighting their unique benefits, how they differ from traditional jib cranes, their various types—including freestanding jib cranes, wall-mounted jib cranes, ceiling-mounted jib cranes, articulating jib cranes, and pillar jib cranes—and why they have become crucial for modern industrial operations.

Explore more about How to choose a Jib Crane to fully harness these intelligent solutions in your facility.

Traditional jib cranes provide a straightforward lifting solution—simple, effective, and dependable. However, as industrial demands grow more complex, the integration of smart technologies has significantly enhanced their capabilities. A smart jib crane is a crane equipped with advanced features such as automation systems, IoT integration, real-time monitoring, and enhanced safety protocols.

Unlike their traditional counterparts, smart jib cranes allow operators to perform tasks with greater precision, safety, and efficiency, ensuring reliable operations in even the most demanding environments. Let's explore in detail the technologies that transform standard jib cranes into smart solutions.

Smart jib cranes incorporate several cutting-edge technologies designed to optimize their performance and provide superior operational control:

Modern smart jib cranes utilize automation and precision control systems, significantly enhancing handling accuracy and repeatability. Operators can effortlessly manage complex maneuvers with minimal manual intervention, reducing operational fatigue and error.

With IoT-enabled sensors and software, smart jib cranes provide real-time operational data. This capability enables operators and supervisors to track equipment performance, usage patterns, load capacities, and maintenance needs proactively.

Utilizing data collected via IoT sensors, smart jib cranes anticipate potential issues before they occur. This predictive maintenance feature ensures minimal downtime and significantly reduces maintenance costs, enhancing overall productivity.

Safety remains paramount in crane operations. Smart jib cranes feature intelligent safety mechanisms such as automated load sensing, anti-collision systems, overload protection, and emergency stop functionalities, protecting workers and machinery alike.

The diverse range of jib crane types allows facilities to select the perfect solution based on their specific operational requirements. Here’s an overview of common smart jib crane variants:

A robust, standalone solution anchored securely to the floor, freestanding jib cranes offer complete 360-degree rotation, ideal for areas needing extensive lifting range and flexibility.

Applications:

Manufacturing plants

Heavy-duty assembly lines

Open storage areas

Ideal for facilities with limited floor space, wall-mounted jib cranes attach directly to walls or vertical structures, providing efficient lifting capabilities without obstructing floor space.

Applications:

Compact warehouses

Production lines near walls

Maintenance bays with space constraints

Leveraging overhead structures for mounting, ceiling-mounted jib cranes offer optimal space efficiency, freeing valuable floor area for equipment and workflows.

Applications:

Laboratories

Cleanroom environments

Precision assembly areas

The articulating jib crane features a multi-jointed arm, allowing precise navigation around obstacles and ensuring highly accurate material placement in challenging environments.

Applications:

Automotive assembly

Complex manufacturing setups

Workshops with limited maneuverability

Stable and reliable, the pillar jib crane offers exceptional performance for stationary lifting tasks, typically mounted on robust columns or pillars, making them suitable for heavy-duty industrial usage.

Applications:

Metalworking and machining stations

Heavy manufacturing

Permanent workstation lifting solutions

For more information, explore Types of Jib Cranes and Ideal Applications.

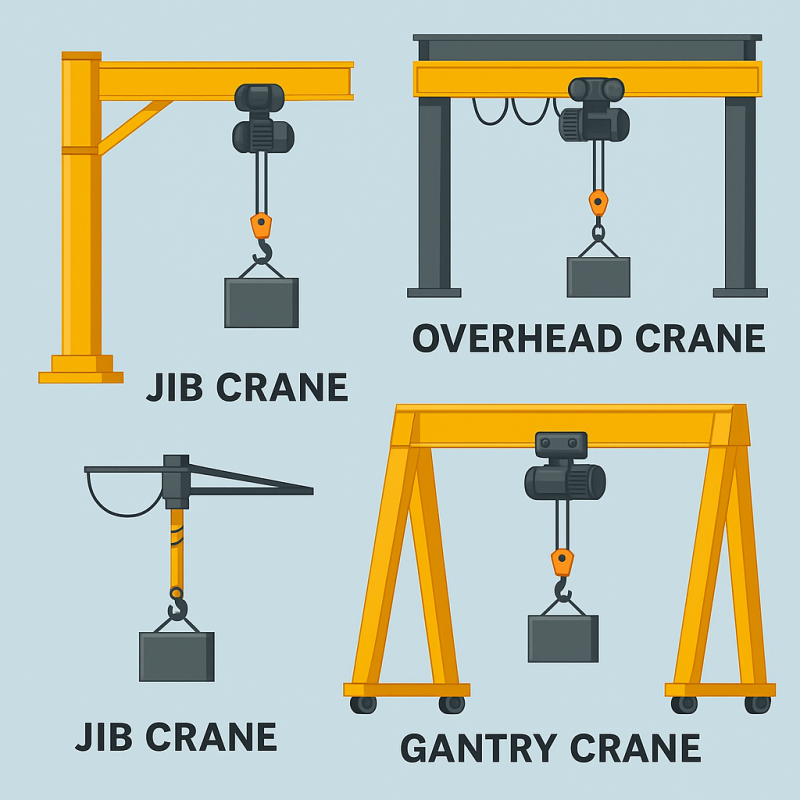

Understanding the key differences between jib cranes and other lifting solutions like overhead cranes helps clarify when a smart jib crane is the optimal choice:

Precision: Smart jib cranes offer superior precision, ideal for tasks requiring meticulous handling and precise material placement.

Cost Efficiency: Generally less expensive to install and maintain, jib cranes present a more budget-friendly option compared to overhead cranes.

Space Utilization: Jib cranes are exceptional for operations where space is limited or precision movement within a confined area is critical, whereas overhead cranes require expansive, structurally reinforced areas.

Learn more by Comparing Jib Cranes vs Overhead Cranes.

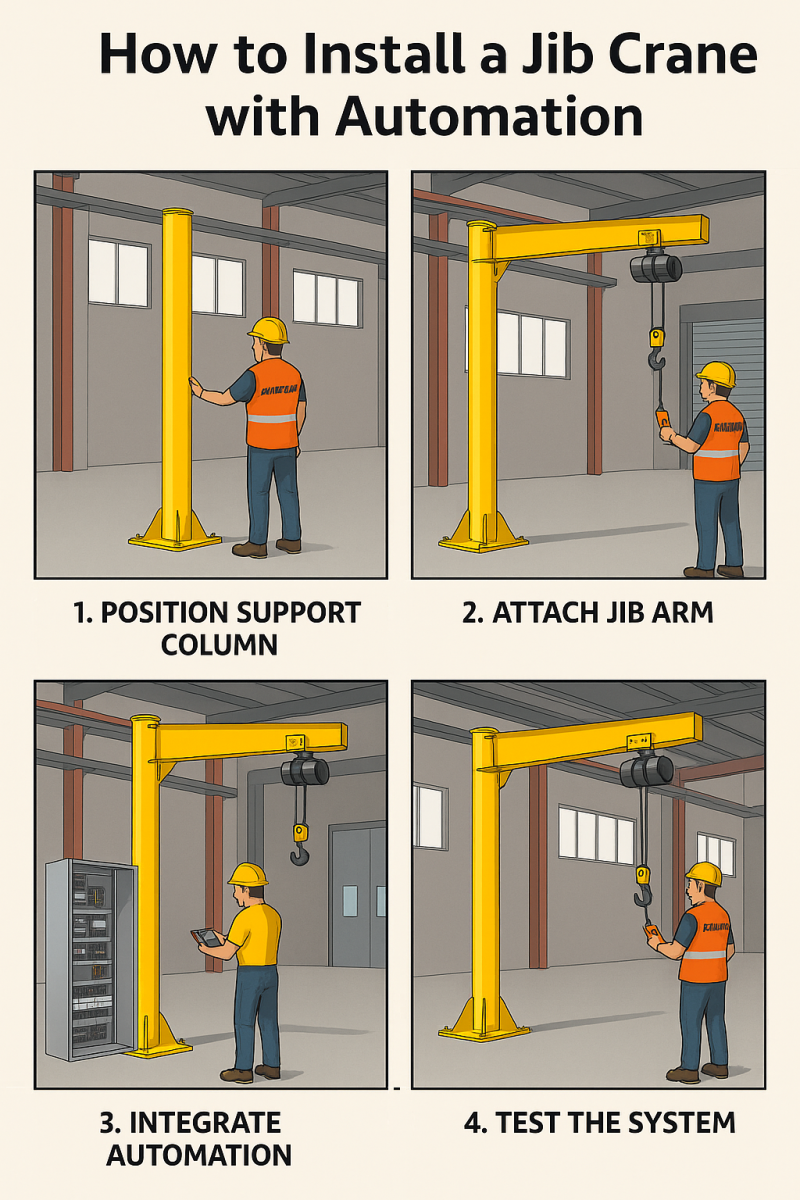

To effectively deploy smart jib crane solutions, following structured steps ensures seamless integration and maximum operational benefit:

Operational Assessment: Evaluate facility needs, operational tasks, and workspace constraints.

Type Selection: Choose the ideal jib crane type based on your operational assessment and spatial considerations.

Integration of Smart Features: Identify necessary smart technologies (automation, IoT, predictive analytics) to include.

Installation and Calibration: Proper installation aligned with manufacturer specifications, ensuring optimal performance and safety.

Testing and Commissioning: Thorough testing and commissioning of smart systems to ensure seamless integration.

Operator Training: Comprehensive training for operators to effectively utilize smart crane functionalities.

Regular Maintenance and Inspection: Maintain optimal performance and safety through regular checks and preventative maintenance.

Detailed insights are available in our Step-by-step Guide to Smart Jib Crane Implementation.

A strategic approach to smart jib crane deployment includes precise planning regarding operational requirements, spatial assessments, and technological integrations:

Evaluate long-term productivity gains and safety improvements.

Consider future operational expansions or adjustments.

Plan for scalable solutions to meet evolving operational demands.

Discover practical tips in our guide on How to Plan for Smart Jib Crane Deployment.

Investing in smart jib cranes is more than just an operational upgrade—it’s a strategic decision towards enhancing your facility’s overall productivity, safety, and competitiveness. By embracing advanced technology, your operations become not only more efficient but also safer and more adaptable to future demands.

Learn more about harnessing the potential of these advanced lifting solutions by exploring further resources:

Ultimately, adopting smart jib cranes positions your business at the forefront of industrial efficiency and innovation, delivering sustainable long-term value.

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.