Among the most versatile and reliable options available are Jib Cranes. By leveraging advanced technologies, modern jib cranes have evolved beyond their traditional roles, offering not only reliable lifting but also intelligent features to maximize productivity, safety, and operational efficiency.In today's fast-paced industrial world, efficiency and safety are key to maintaining competitiveness and profitability.

In this article, we’ll explore how to fully maximize the potential of advanced jib crane solutions, understand the diverse range of jib crane types, and learn to effectively implement and maintain these valuable assets.

Discover why jib cranes provide a straightforward lifting solution for any industrial environment.

Jib cranes are engineered to perform lifting operations with precision and reliability. Traditionally, these cranes have served as essential tools in warehouses, manufacturing plants, and production facilities, efficiently transferring materials within specific workspaces. Today, integrating smart technology significantly enhances their functionality, making them indispensable components of modern industrial workflows.

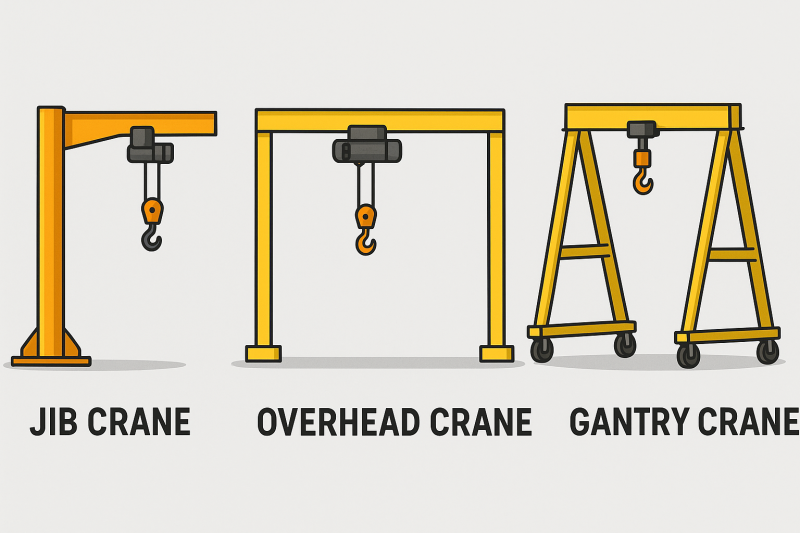

Advanced jib cranes, including freestanding jib cranes, wall-mounted jib cranes, ceiling-mounted jib cranes, articulating jib cranes, and pillar jib cranes, deliver robust lifting solutions adapted to diverse operational requirements.

Explore the comprehensive Types of smart jib cranes to match your specific needs.

Smart jib cranes are equipped with intelligent systems that go far beyond basic lifting capabilities. Here’s why integrating these advanced lifting solutions is crucial:

Safety is paramount in lifting operations. Smart jib cranes feature intelligent safety systems, including automated emergency stops, collision avoidance sensors, and overload protection. These technologies significantly reduce human error, enhancing workplace safety and reducing the risk of injuries and operational interruptions.

Smart jib cranes leverage automation and precision controls to optimize workflow. This leads to faster lifting cycles, reduced downtime, and increased productivity, crucial for maintaining competitive efficiency in modern industrial environments.

Advanced jib crane systems are designed with flexibility in mind. Their smart functionalities can easily adapt to evolving operational demands, ensuring that your investment remains valuable and scalable as your business grows.

Choosing the ideal jib crane involves understanding each type's capabilities and applications. Below, we explore the core types of smart jib cranes available today:

A freestanding jib crane offers a full 360-degree rotation, making it highly suitable for versatile, heavy-duty operations. It requires a secure foundation, providing unmatched stability and extensive reach for large industrial areas.

Ideal Applications: Assembly lines, heavy manufacturing, open warehouse spaces.

A wall-mounted jib crane maximizes available space by mounting directly to existing structural supports, eliminating the need for floor space.

Ideal Applications: Workshops, loading docks, confined production areas.

The ceiling-mounted jib crane excels in environments where floor space is a premium. Mounted overhead, it allows for efficient lifting operations without interfering with production activities below.

Ideal Applications: Laboratories, precision manufacturing facilities, compact assembly areas.

An articulating jib crane features a multi-jointed arm, providing flexible maneuverability and precision positioning around obstacles, ideal for complex workspaces.

Ideal Applications: Automotive production, machining areas, intricate assembly lines.

A pillar jib crane is securely fixed to a strong column, offering superior stability and robust performance, especially suited to repetitive and demanding lifting tasks.

Ideal Applications: Fabrication shops, heavy-duty machining centers, maintenance areas.

Gain a deeper insight by reading more about the diverse range of jib crane types.

One significant advancement in jib crane technology is automation. Automated systems increase efficiency and consistency, reducing errors and operator fatigue.

Modern smart jib cranes utilize automation to perform repetitive lifting tasks accurately, consistently, and safely. Automation capabilities include:

Precise load positioning

Automated collision detection

Load monitoring and real-time feedback

Predictive maintenance alerts and diagnostics

By harnessing automation, businesses can significantly enhance operational performance while minimizing human error.

Properly choosing and installing your jib crane is critical to maximizing its potential. Follow these crucial steps:

Assess Operational Needs: Evaluate load capacities, workspace limitations, and operational requirements.

Select Appropriate Jib Crane Type: Match crane type (freestanding, wall-mounted, ceiling-mounted, articulating, or pillar jib crane) to your facility’s needs.

Integration of Smart Features: Prioritize smart features that align with operational objectives, including automation, safety, and maintenance capabilities.

Expert Installation: Proper installation ensures maximum efficiency and safety. Engage with experienced installers familiar with smart jib crane systems.

Testing and Certification: Thoroughly test the crane’s functionality, safety systems, and automated features before full operation.

Operator Training: Comprehensive training ensures operators understand advanced crane features, promoting safer and more efficient operations.

Explore in detail about Choosing and Installing the Right Jib Crane.

Modern jib cranes incorporate several intelligent technologies to enhance their efficiency and reliability:

Real-Time Load Monitoring: Provides continuous feedback on load conditions and crane status, optimizing safety and operational performance.

Intelligent Safety Systems: Include automated emergency stops, collision avoidance, and overload sensors, dramatically increasing workplace safety.

Predictive Maintenance: Smart sensors detect potential issues early, reducing downtime through proactive maintenance.

IoT Integration: Enables remote monitoring, operation diagnostics, and efficient performance management from any location.

Discover more in-depth information about Key Smart Features in Modern Jib Cranes.

The integration of smart jib cranes into industrial operations significantly enhances productivity, safety, and scalability. Their intelligent features transform lifting processes, minimizing downtime, and providing unmatched operational reliability.

Choosing the appropriate crane type, understanding its smart functionalities, and implementing it effectively ensures maximum return on investment and operational excellence. Begin your journey by exploring the advanced capabilities of jib cranes, and fully realize the potential of these advanced lifting solutions today.

References

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.