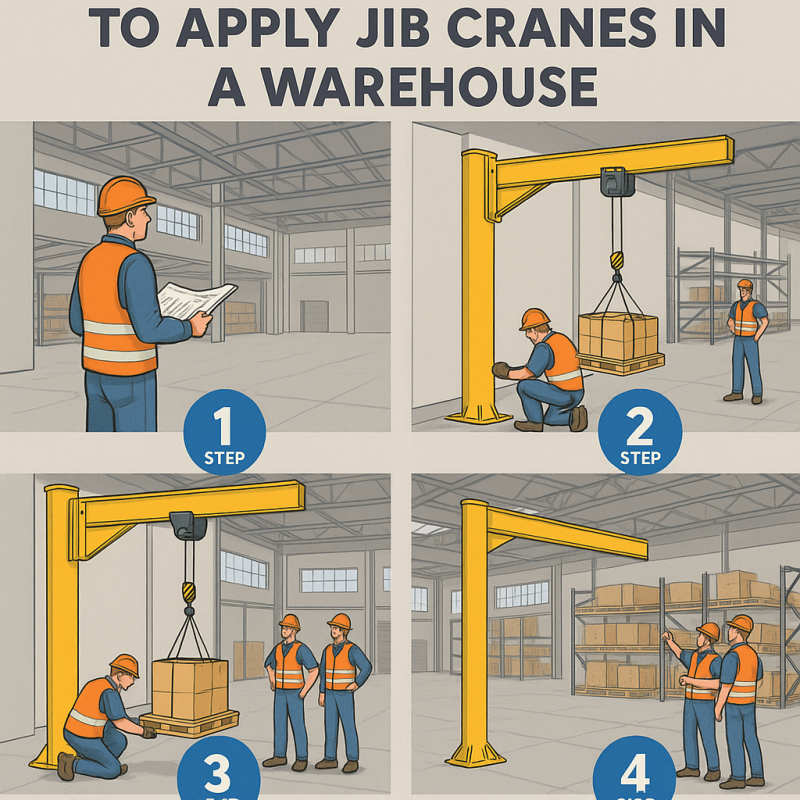

With automation, they’ve evolved into intelligent systems that enhance productivity, safety, and precision in material handling. But implementing an automated jib crane system requires a well-defined step-by-step process.

Whether you’re installing a freestanding jib crane, integrating a wall mounted jib crane, or upgrading to a smart articulating system, this guide outlines the essential steps you need to follow for successful implementation.

Not sure what the basic purpose is? Start with what is a jib crane used for to understand their foundational role in modern operations.

Before choosing automation, define the key performance indicators (KPIs) and use cases:

What type of loads will be lifted?

How often will lifts occur?

Is precision placement required?

Will the crane operate independently or as part of an automated production line?

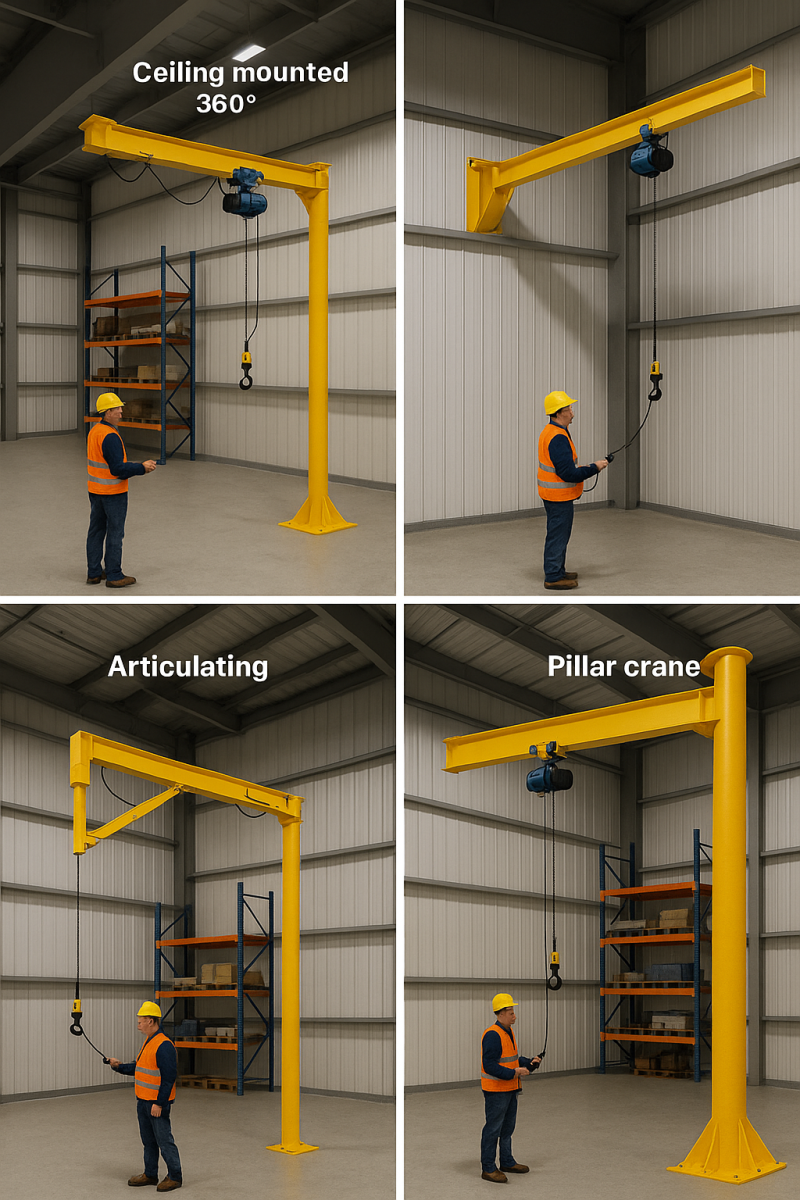

These questions determine whether a ceiling mounted jib crane or an articulating jib crane with smart sensors is more suitable for your operation.

For detailed classifications, check out what are jib crane types.

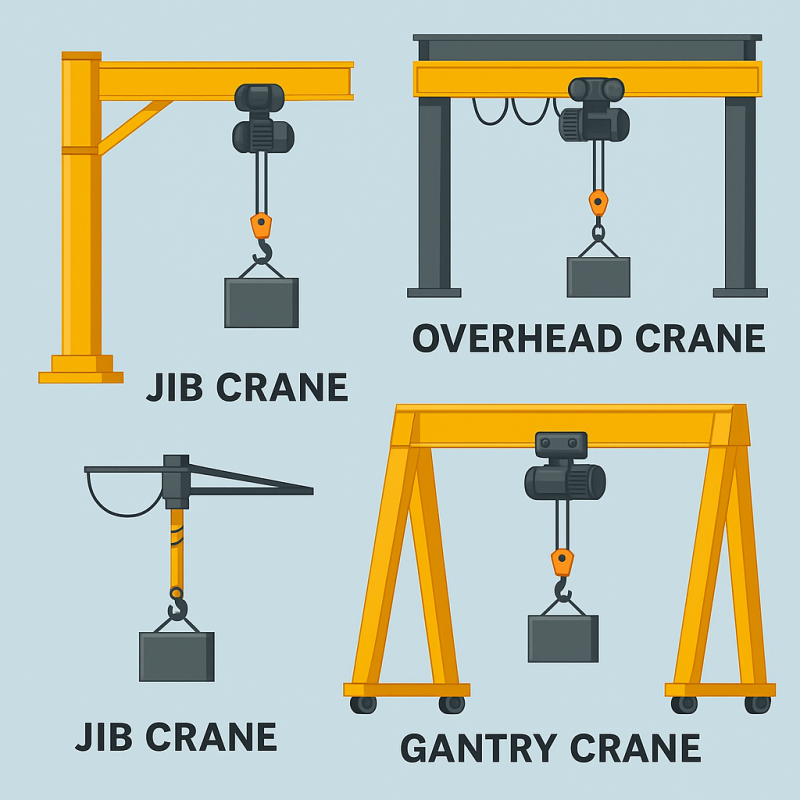

Not all jib cranes are equally suited for automation. Here’s a breakdown:

Freestanding Jib Crane: Offers 360° rotation and is excellent for central work areas.

Wall Mounted Jib Crane: Great for saving floor space and integrating into workstation layouts.

Ceiling Mounted Jib Crane: Keeps the floor clear and integrates with overhead systems.

Articulating Jib Crane: Best for working around obstacles and offering multi-axis movement.

Pillar Jib Crane: Compact for light-duty use but limited in reach and load.

Compare this with traditional options in Jib cranes and overhead cranes solutions.

Every site has different limitations:

Floor thickness and reinforcement (for freestanding cranes)

Wall strength (for wall-mounted variants)

Ceiling beams and trusses (for overhead installations)

Also, assess:

Load weight and size

Frequency of lifts

Required working radius and lifting height

Safety clearances and obstacles

Automated jib cranes typically include:

Motorized trolleys and hoists

Programmable logic controllers (PLCs)

Load detection sensors

Collision avoidance systems

Remote control or app-based interfaces

Depending on your application, you might also need:

Zone limiters

IoT connectivity for data logging

Integration with WMS or ERP platforms

Need step-by-step technical help? Read how to build a jib crane.

Each jib crane type requires a different foundation:

Freestanding units: Concrete pads with anchor bolts

Wall-mounted types: Load-bearing walls or columns

Ceiling-mounted types: Steel beams rated for dynamic loads

If you're designing for a wall-mounted unit, see this live product guide: How to build a jib crane wall-mounted.

Installation must follow manufacturer guidelines and usually includes:

Assembling base, mast, and boom

Aligning and leveling the crane

Installing the hoist and trolley systems

Wiring control panels and motors

Setting up PLC parameters and automation logic

Safety testing and load verification

Some systems include plug-and-play automation kits, but others may require engineering support.

For field-tested installation tips, check how to apply a jib crane wall-mounted.

No automation system is effective without properly trained staff. Training should include:

How to use the remote control or HMI panel

Interpreting sensor alerts and system warnings

Emergency stop procedures

Daily and weekly maintenance routines

Consider certification where applicable, especially in facilities governed by ISO, OSHA, or local safety standards.

To maximize your ROI, the automated jib crane must be integrated with existing processes. That may include:

Material tracking systems

Automated conveyors

Pick-and-place robots

Maintenance tracking dashboards

Monitor KPIs such as:

Lift frequency and cycle times

Downtime incidents

Maintenance alerts and fault codes

Operator efficiency and safety compliance

Explore how these elements are evolving in How Automation Transforms Jib Crane Functionality.

Automation introduces more electronics, which require scheduled checks:

Weekly inspections of wiring, hoists, and sensors

Monthly lubrication and load testing

Quarterly software updates and diagnostics

Annual structural audits

Predictive maintenance systems can automate alerts based on usage data.

When you automate a jib crane, think beyond your current needs. Consider:

Adding additional cranes with shared control units

Integrating machine vision for AI-based load tracking

Expanding sensor systems to detect wear and corrosion

This scalability ensures your investment continues to deliver value as your operation grows.

Implementing an automated jib crane involves more than simply choosing a crane model—it’s a strategic process. From evaluating the workspace and selecting the right crane type to automating movement and integrating with your digital systems, each step is vital.

If you're at the beginning of this journey, first understand what is a jib crane used for. Then explore your ideal solution, from structural types to control systems.

With careful planning and step-by-step execution, your smart jib crane will become a cornerstone of operational efficiency and workplace safety.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.