Jib Cranes, once simple manual machines, are now at the forefront of automation and Industry 4.0. With the integration of smart controls, sensors, and remote operations, automated jib cranes are transforming productivity, safety, and workflow efficiency.

If you're new to the concept, first explore what is a jib crane to understand its fundamentals.

Jib cranes are lifting devices featuring a horizontal boom, or jib, that supports a hoist. They allow localized, radial movement of loads and are ideal for small to mid-scale operations where flexibility and floor space optimization are crucial.

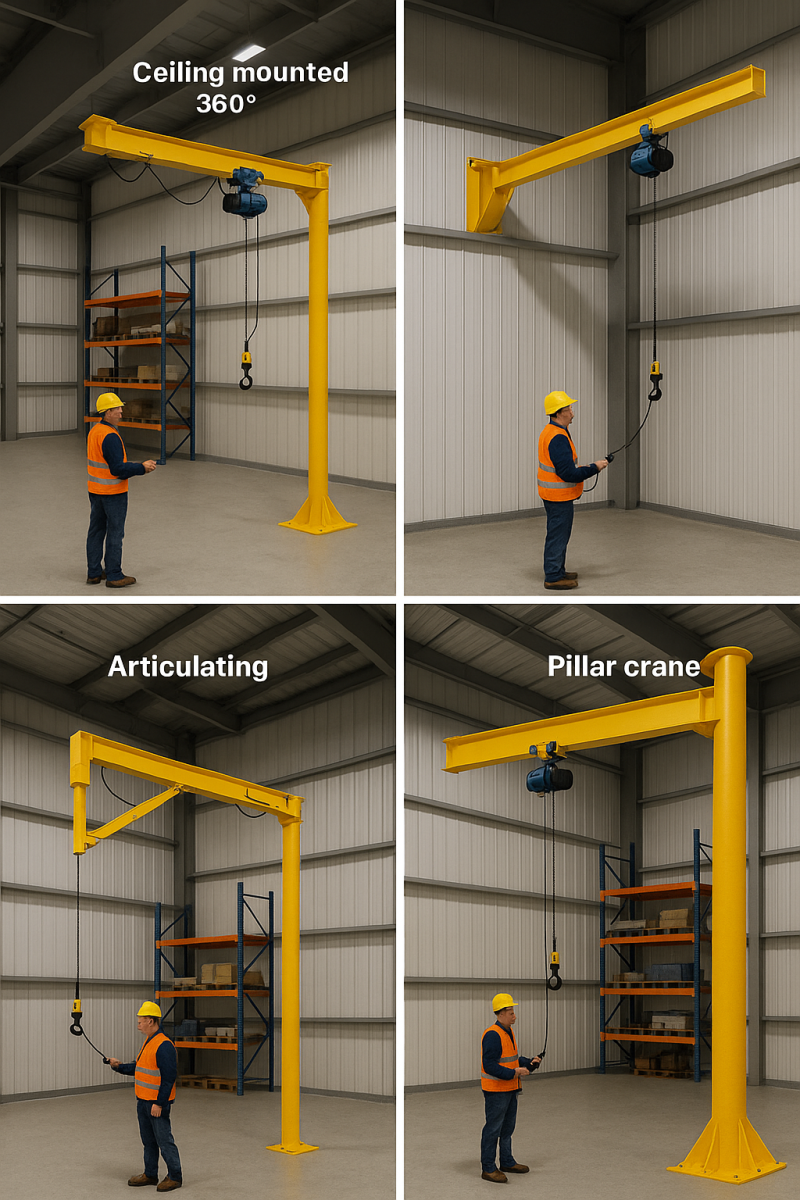

Depending on the design and mounting location, these cranes come in various configurations:

Freestanding jib crane: Mounted on concrete floors, offering 360° rotation.

Wall mounted jib crane: Attached to vertical surfaces, ideal for compact spaces.

Ceiling mounted jib crane: Suspended from overhead beams, saving floor space.

Articulating jib crane: Has two swivel arms for navigating around obstacles.

Pillar jib crane: Compact version for workstation lifting.

Want a deeper look at configurations? Explore what is jib crane type.

Historically, jib cranes were operated manually or with basic electric hoists. While effective, these systems are limited by:

Human fatigue

Inconsistent load handling

Safety risks due to human error

Lack of real-time data or diagnostics

Automation introduces:

Motorized slewing and trolley motion

Load detection and torque sensors

Programmable lifting and placement

Remote control and diagnostics via smart apps

Integration with WMS/ERP systems

This leap in capability is fueling the shift to automation. Compare differences in Jib cranes and overhead cranes solutions.

Smart controllers enable millimeter-accurate positioning. Automated trolleys and hoists can move loads to programmed points without deviation. This is critical for tasks involving:

Fragile or irregularly shaped objects

Assembly line precision

Inventory slotting in racking systems

Automated jib cranes use real-time monitoring to detect:

Overloads

Sudden torque changes

Unauthorized zone entry

This reduces accident risks and supports compliance with workplace safety regulations.

Sensors track crane usage, motor performance, and structural vibration. Operators receive alerts when components need inspection or servicing—reducing unexpected breakdowns.

Automated cranes can be synchronized with:

Conveyor belts

Robotic arms

Warehouse management systems

This results in seamless material flow from receipt to assembly.

Learn how to configure these systems through how to operate a jib crane.

An articulating jib crane equipped with smart sensors helps lift automotive parts from the supply line to the assembly bench with:

Variable speed control

Torque-limiting hoist

Zonal movement presets

Wall-mounted jib cranes automate repetitive lifting of boxes from pallets to racks using RFID-tag matching, ensuring accurate placement.

Portable pillar jib cranes use automated controls to handle pump parts or turbine components for repair with safety interlocks.

If you're considering a build, learn how to build a jib crane.

| Type | Automation Compatibility | Best Use Case |

|---|---|---|

| Freestanding | High | Wide floor coverage in open areas |

| Wall Mounted | Moderate–High | Production lines with limited floor space |

| Ceiling Mounted | High | Cleanroom or large factories |

| Articulating | High | Navigating around obstructions |

| Pillar Mounted | Moderate | Workstation precision handling |

Ready to choose a model? See how to apply a jib crane.

Reduced Labor Costs: One operator can control multiple cranes remotely.

Faster Throughput: Repetitive tasks are completed quickly with automation logic.

Minimized Downtime: Predictive maintenance keeps systems in top shape.

Data Insights: Load cycle data informs optimization strategies.

Before upgrading to an automated jib crane, consider:

Load Profile: Max weight, shape, frequency

Rotation Needs: 180°, 270°, or 360° coverage

Integration: Does your facility use WMS/SCADA/IoT systems?

Training: Operators will need instruction in using control interfaces and diagnostics tools

Compliance: Check with local regulations for machine safety and electrical approvals

Looking ahead, expect these smart enhancements:

AI-based load balancing

Auto-learning path optimization

Voice-activated crane operation

Self-diagnostic systems with cloud sync

Explore broader implications in Why Automation and Smart Jib Cranes Are the Future.

Jib Cranes are no longer limited to simple lifting operations. Automation has unlocked a new era of smart, efficient, and safe material handling. Whether you choose a freestanding jib crane for heavy lifting or an articulating model for tight spaces, automation makes it faster, smarter, and more precise.

Get started today by reviewing what is a jib crane and choosing a crane model that fits your operational vision.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.