Jib Cranes have emerged as a versatile, affordable solution that checks all the boxes for material handling across a wide range of environments—from compact workshops to large-scale distribution centers.

Whether you opt for a freestanding jib crane, a wall mounted version, or an articulating model, the return on investment is both immediate and long-term. In this article, we’ll explore the key reasons why jib cranes represent a cost-effective investment—and how to choose the right type for your needs.

Discover how Jib cranes help you get more done in less time while minimizing overhead.

One of the biggest advantages of jib cranes is their adaptability. They're widely used in sectors such as:

Manufacturing

Warehousing and logistics

Automotive workshops

Construction and maintenance

Shipyards and ports

These cranes are especially ideal where repetitive lifting operations occur in fixed zones.

Explore how Jib cranes work well in many industries, thanks to their range of motion and customizable design.

Each crane type offers distinct advantages depending on your application, budget, and space constraints.

Requires a foundation, but supports heavy loads and 360° rotation

No dependence on existing building structure

Ideal for indoor or outdoor standalone operations

Low maintenance with long lifespan

Attached to structural walls or columns

Conserves floor space and installation cost

Suitable for tight assembly lines or workstations

Lower price point than freestanding models

Suspended from the ceiling, freeing up all floor area

No need for dedicated structural foundation

Seamlessly integrates with automated material flow

High ROI in clean or space-sensitive facilities

Offers enhanced reach through dual-arm movement

Navigates around columns, machinery, or walls

Increases efficiency in crowded or irregular spaces

Excellent for CNC or injection molding operations

Mounted on a fixed column, great for workbench-level use

Ideal for lightweight, repetitive lifts

Easy to install and relocate

Minimal operating cost over time

If you're unsure which to choose, see why Jib cranes are a smart choice in comparison to other lifting equipment.

Unlike overhead or gantry cranes that require extensive engineering, structural supports, and permanent rail systems, jib cranes can often be installed with minimal civil work. This reduces:

Engineering and construction costs

Installation time

Interruption to facility workflow

And remember, Choosing the right crane is just the first step. Proper planning ensures maximum efficiency and minimum downtime.

Jib cranes are designed for efficiency and ease of use. With a simple pivot mechanism and smooth trolley system, operators can handle heavy loads with minimal effort.

This leads to:

Faster cycle times

Reduced need for multiple workers per lift

Increased safety and reduced injury risk

Consistent load positioning

They’re perfect for operations where Jib cranes lift and shift goods without needing a large setup.

Jib cranes have fewer moving parts compared to other lifting systems. This translates to:

Lower maintenance costs

Reduced need for specialized service

Less downtime due to mechanical failure

Most models require only periodic lubrication and occasional inspections, keeping operational costs low.

Floor space is money—especially in modern facilities. Jib cranes, particularly wall or ceiling-mounted versions, offer compact designs that don’t interfere with workflow.

No floor rails required

No dedicated lift zones

Perfect for workstations, docks, and corners

They truly shine where compact lifting solutions come in handy.

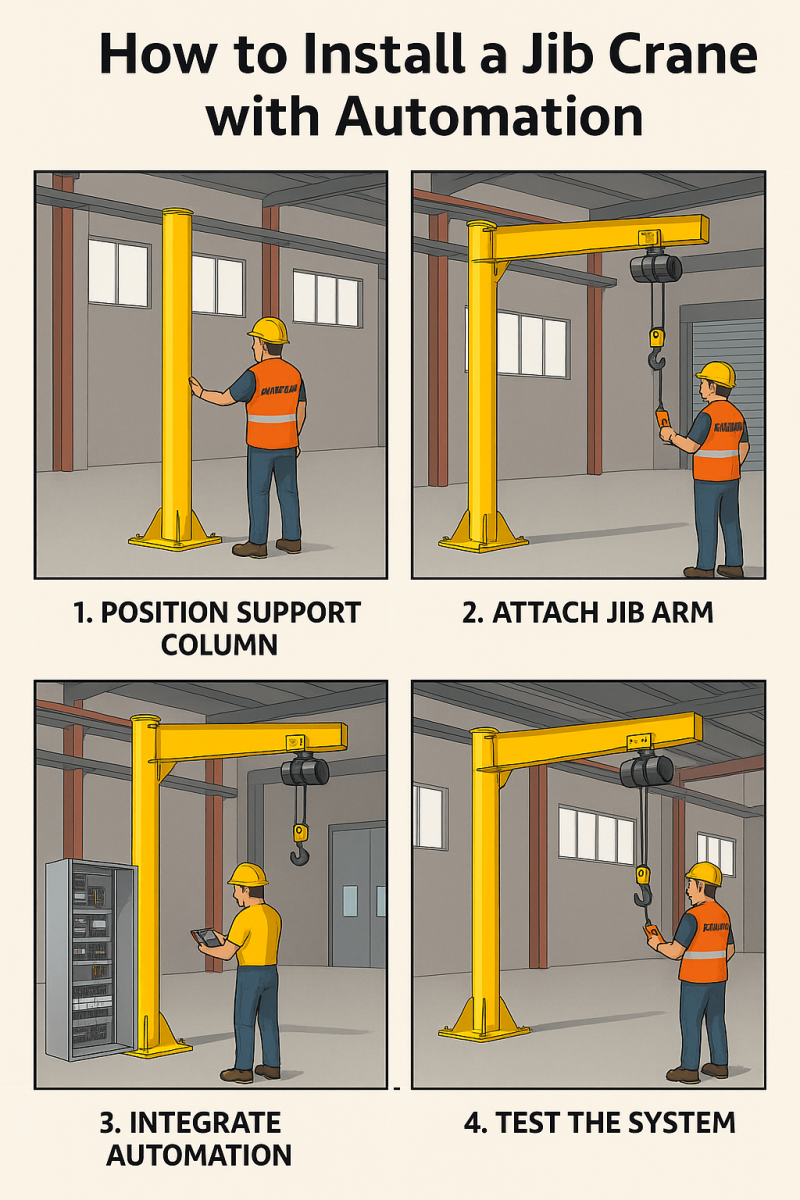

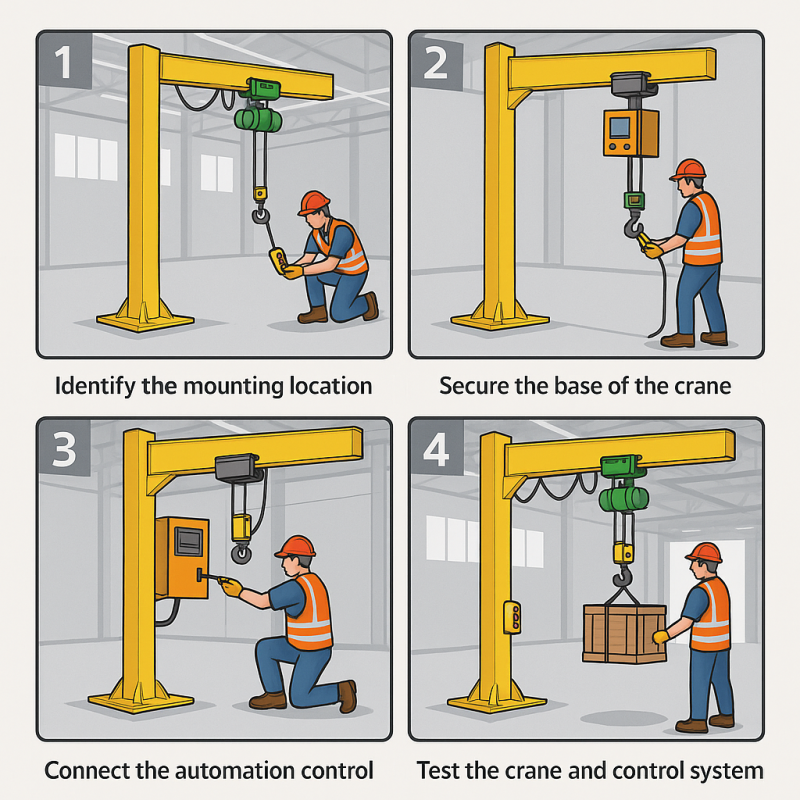

Many jib cranes today are compatible with automation features:

Remote controls

Variable-speed drives

Load sensors and overload alarms

IoT integration for tracking and diagnostics

This gives you the flexibility to upgrade your crane as your operations grow—without needing to replace your entire system.

Want more on this topic? Dive into Compact Lifting Solutions: Why Jib Cranes Are a Smart Investment.

Imagine a small metal fabrication shop. They need to move steel beams between cutting and welding stations. Instead of installing an expensive overhead crane system, they opt for:

A wall-mounted jib crane in the cutting zone

An articulating jib crane near the welding booth

Total cost: A fraction of a gantry crane.

Result: Load transfer time drops by 50%, with zero additional headcount.

If you're seeking a lifting solution that delivers immediate value and long-term savings, Jib Cranes are hard to beat. They’re adaptable, efficient, and cost-effective—offering performance enhancements in both manual and automated facilities.

Whether you're just starting out or looking to scale, these cranes help you grow without growing your footprint or budget.

Looking for your best-fit model? Revisit the benefits of how Jib cranes help you get more done in less time or speak to a specialist about your installation requirements today.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.