These cranes are used in various environments, from construction sites and shipyards to factories and warehouses. But to truly harness the benefits of this versatile equipment, it's essential to understand how a gantry crane works — from its components to its lifting mechanisms, movement systems, and safety features.

In this comprehensive guide, we’ll explore the key components and working mechanics of gantry cranes, examine their use across industries, and show how Aardwolf gantry crane systems offer innovative, customizable solutions for modern lifting demands.

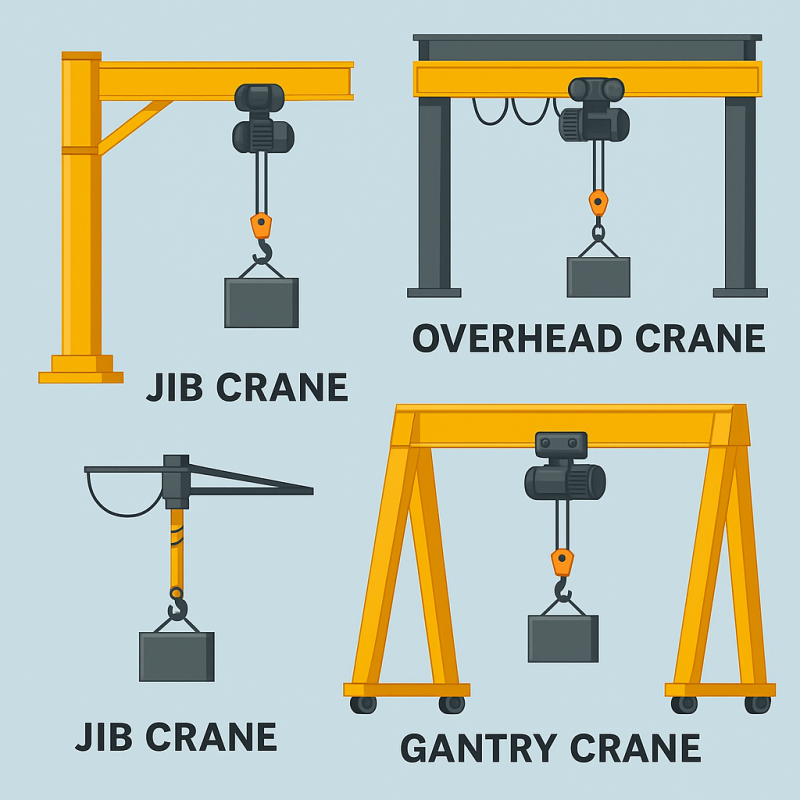

A gantry crane is a type of overhead crane with one or two freestanding legs that move along tracks or wheels. Unlike fixed overhead cranes that require permanent structural support, gantry cranes offer mobility, flexibility, and easy setup in almost any location.

Gantry cranes consist of a horizontal beam or bridge, supported by two vertical legs, which rest on wheels or rails. A trolley with a hoist moves along the bridge, allowing loads to be lifted and moved both vertically and horizontally.

Aardwolf gantry cranes are engineered with both indoor and outdoor environments in mind. Their products are known for durability, adaptability, and precision handling — making them ideal for use in industries where efficiency and safety are non-negotiable.

Understanding how a gantry crane works starts with the two core functionalities: lifting and moving loads. Gantry cranes operate by combining vertical lift with horizontal travel, allowing precise load handling.

The hoist is the primary mechanism that lifts and lowers the load. Powered by an electric or manual motor, the hoist pulls a wire rope or chain over pulleys or a drum to raise heavy items. The Aardwolf Electric Hoist, for instance, offers reliable lifting performance with smooth acceleration and adjustable speed control.

The trolley, mounted on the bridge, travels horizontally across the span of the crane. This trolley carries the hoist and allows for left-to-right or front-to-back motion, positioning the load exactly where it's needed.

Aardwolf Trolley Systems are designed for high-precision applications, offering manual or motorized options depending on the user’s requirements.

Some gantry cranes — especially portable or adjustable models — allow height adjustment via telescoping legs or hydraulic systems. This feature is crucial when lifting materials through doorways, onto rooftops, or under obstructions.

The Aardwolf Adjustable Gantry Crane enables users to modify beam height to meet the requirements of each job, increasing flexibility and safety.

Once the crane positions the load correctly, the hoisting motor slows down for accurate placement. Most modern gantry cranes are equipped with limit switches, braking systems, and overload protection to ensure safety during operation.

Aardwolf cranes include safety-first designs with integrated mechanical stops, anti-drop devices, and hoist overload detection systems.

The hoist is the core lifting mechanism and typically includes a motor, drum, wire rope or chain, and lifting hook. Aardwolf's hoists are available in manual, electric, and chain-driven versions to meet varying operational loads.

The trolley moves along the beam, supporting the hoist. Aardwolf trolleys come with adjustable flanges and sealed bearings, ensuring low maintenance and consistent movement under load.

The bridge is the horizontal beam connecting the two legs. Aardwolf bridges are made from reinforced steel or lightweight aluminum, providing strength without sacrificing portability.

Legs support the bridge and hold the entire crane upright. End trucks are mounted at the base and contain wheels or gear drives to allow movement. Aardwolf cranes feature heavy-duty end trucks with optional pneumatic tires for outdoor use.

Mobility is achieved using casters, rubber wheels, or steel V-groove wheels depending on surface conditions. Aardwolf offers crane models equipped with polyurethane wheels for indoor use and pneumatic tires for uneven terrain.

From pendant controllers to remote wireless units, the control system allows the operator to manage lift, travel, and load speed. Aardwolf ergonomic control systems support both basic and advanced automation requirements.

Aardwolf is a trusted name in lifting solutions, known for engineering precision, durability, and versatility into every product. Their gantry crane models are designed for real-world industrial needs — from construction and fabrication to warehousing and maintenance. Below are some of the top-performing Aardwolf gantry crane models and their standout features.

Best for: Maintenance shops, small workshops, service vans, and mobile fabrication.

Lightweight and Modular: Designed for easy transport and on-site assembly.

Quick Setup: Can be rolled into position and made operational within minutes.

Load Capacity: Up to 2000 kg (2 tons), ideal for handling light-to-medium loads.

Compact Storage: Breaks down for convenient storage and transportation.

Optional Accessories: Can be paired with Aardwolf manual chain blocks or electric hoists for complete lifting functionality.

Best for: Workspaces with variable lifting requirements and overhead clearance challenges.

Telescopic Legs: Adjust the height to accommodate different load sizes and environments.

Custom Spans Available: Choose the beam span according to workspace needs.

Height Range: Typically adjustable from 2.5 to 4 meters (custom heights available).

Easy Mobility: Equipped with heavy-duty casters or track-compatible wheels for smooth travel.

Robust Construction: Made from powder-coated steel or aluminum for corrosion resistance.

Best for: Rooftop installations, HVAC work, glass lifting, and environments where corrosion is a concern.

Ultra-Lightweight Design: Can be lifted and moved manually by two workers.

Weather Resistant: Aluminum structure ensures long-term performance in outdoor settings.

No Welding Required: Bolt-together construction for easy field assembly.

Capacity Range: Typically supports up to 1500 kg (1.5 tons), depending on configuration.

Optional Pneumatic Wheels: For easier transport across soft or uneven terrain such as gravel, rooftops, or grass.

Best for: Heavy-duty lifting applications in construction, utilities, or industrial yards.

High Load Capacity: Handles up to 15 tons depending on configuration.

Portal Frame Design: Ensures structural strength and stability for large-span lifting.

Motorized Options: Compatible with powered hoists and travel mechanisms for automation.

Durable Finish: Industrial-grade powder coating resists wear, corrosion, and outdoor exposure.

Customized Engineering: Available in custom sizes and load specs for tailored applications.

Best for: Enhancing precision and control across any Aardwolf gantry crane model.

Electric and Manual Options: Choose from chain blocks, wire rope hoists, or geared trolleys.

Smooth Operation: Trolleys include sealed bearings and adjustable flanges for long-term reliability.

Safety Features: Integrated brake systems and overload protection available.

Compatibility: Designed to integrate seamlessly with Aardwolf’s gantry beams.

Best for: Outdoor terrain, construction sites, rooftops, or unpaved surfaces.

All-Terrain Tires: Pneumatic wheels allow for smooth movement across uneven or soft surfaces.

Height-Adjustable Models Available: Combine terrain mobility with vertical flexibility.

Heavy-Duty Framework: Built to withstand rugged job site conditions.

Applications: Perfect for projects where overhead cranes aren't accessible or feasible.

Aardwolf gantry cranes are engineered to meet industry needs with a strong focus on:

Portability: Easy relocation across or between sites

Safety: Built-in fail-safe mechanisms and anti-tilt designs

Adaptability: Interchangeable components and adjustable frames

Durability: Materials selected for longevity in harsh environments

Whether you're lifting stone slabs, machinery, HVAC units, or shipping components, Aardwolf gantry cranes provide the strength, mobility, and customization modern job sites demand.

Aardwolf cranes are used to lift rebar, steel beams, concrete panels, and formwork on job sites. Their portable frames are perfect for moving between work areas.

In warehouses, gantry cranes streamline loading and unloading, material organization, and storage system servicing.

Used for assembly line work, Aardwolf gantries handle heavy parts like motors, molds, and machine components with minimal floor obstruction.

In shipyards, gantry cranes handle engines, propellers, and large assemblies. Aardwolf heavy-duty cranes offer both capacity and corrosion protection for harsh marine environments.

Thanks to lightweight aluminum frames and pneumatic wheels, Aardwolf cranes excel in HVAC installation and rooftop maintenance, reducing crane rental costs and increasing access.

Benefits of Gantry Cranes

Benefits of Gantry CranesEasy to Set Up and Relocate

No foundation or permanent installation required

Cost-Effective

Less expensive than bridge cranes and easily scalable

Highly Customizable

Adjustable height, span, and accessories

Moves Under Load

Aardwolf cranes can be moved with the load still attached

Indoor and Outdoor Versatility

Pneumatic tires for rough terrain, polyurethane casters for smooth surfaces

Safe Operation

Built-in safety mechanisms reduce risk and enhance reliability

While other crane manufacturers offer similar systems, Aardwolf stands out due to:

Superior material quality (reinforced beams, sealed bearings, precision hoists)

Fully modular design for customization

Lightweight aluminum frames for portable tasks

Dedicated range of accessories, like slab lifters, vacuum lifters, and glass carriers, all compatible with Aardwolf cranes

Trusted by global professionals in construction, stone handling, and logistics

Never exceed the crane’s rated load capacity

Inspect the hoist and trolley before each operation

Maintain clean, level surfaces for movement

Avoid moving the crane with swinging or unbalanced loads

Use locking mechanisms and emergency stops when positioning loads

Wear appropriate PPE and receive training before use

Understanding how a gantry crane works is essential for choosing the right solution for your lifting needs. These cranes combine power, mobility, and precision, making them indispensable in industries that rely on heavy material handling.

Aardwolf gantry cranes offer a complete range of customizable solutions tailored for today’s fast-paced industries. Whether you’re lifting slabs on a job site, installing HVAC systems on a rooftop, or moving machinery on a production line, Aardwolf delivers efficiency, safety, and reliability every step of the way.

Are Aardwolf hoists manual or electric?

Both options are available depending on lifting speed and control requirements.

How much weight can an Aardwolf gantry crane lift?

Capacities range from 500 kilograms to over 15 tons, depending on the model.

Can the crane be disassembled for transport?

Yes. Most Aardwolf gantry cranes are designed to be easily dismantled for transport between sites.

Does Aardwolf provide lifting accessories?

Yes, including slab clamps, vacuum lifters, forklift booms, and more — all compatible with their gantry systems.

References

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Inscrivez-vous pour recevoir les dernières informations sur les nouveaux produits Aardwolf, les offres spéciales et plus encore.

En vous inscrivant, vous acceptez de recevoir des e-mails d'Aardwolf contenant des actualités, des offres spéciales, des promotions et d'autres informations. Vous pouvez vous désabonner à tout moment.