A trolley with a hoist mechanism moves along the bridge, enabling precise positioning of heavy loads.

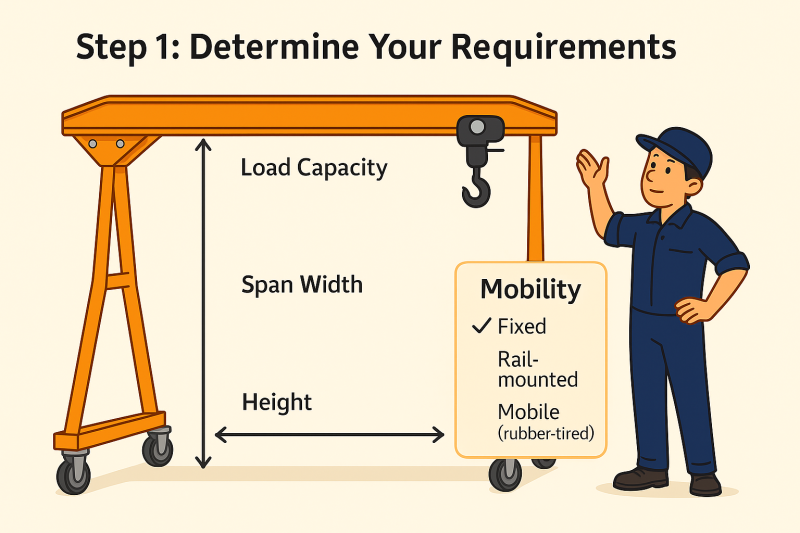

Before starting construction, clearly define your operational requirements:

- Load Capacity: Determine the maximum weight your gantry crane needs to lift.

- Span Width: Decide the required width between the legs.

- Height: Establish the necessary height clearance for your operations.

- Mobility: Choose between fixed, rail-mounted, or mobile (rubber-tired).

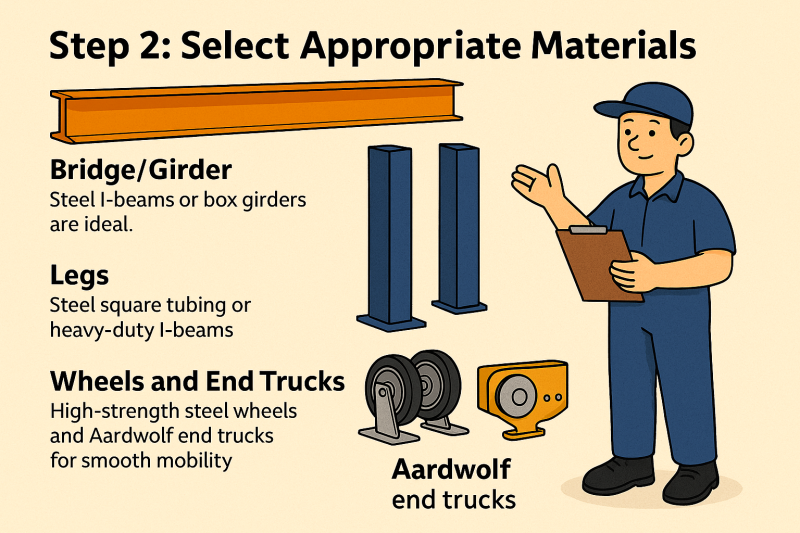

Quality materials are critical to the structural integrity of your gantry crane.

- Bridge/Girder: Steel I-beams or box girders are ideal.

- Legs: Steel square tubing or heavy-duty I-beams.

- Wheels and End Trucks: High-strength steel wheels and Aardwolf end trucks for smooth mobility.

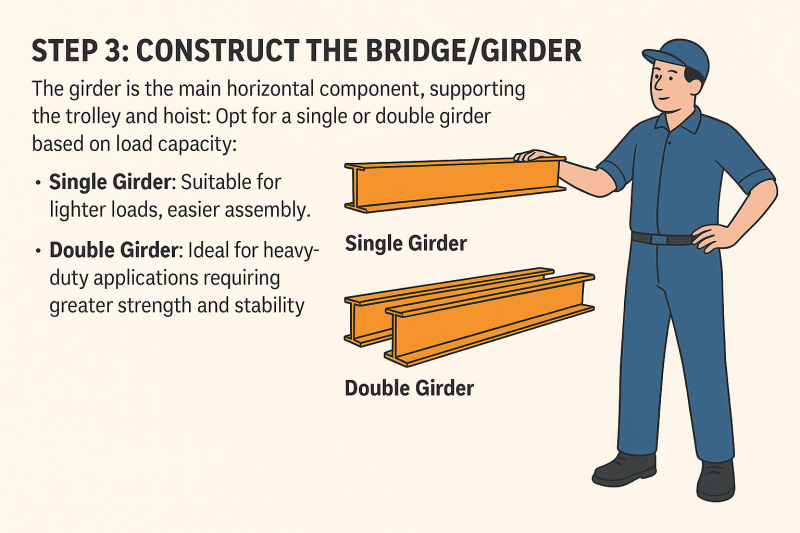

The girder is the main horizontal component, supporting the trolley and hoist. Opt for a single or double girder based on load capacity:

- Single Girder: Suitable for lighter loads, easier assembly.

- Double Girder: Ideal for heavy-duty applications requiring greater strength and stability.

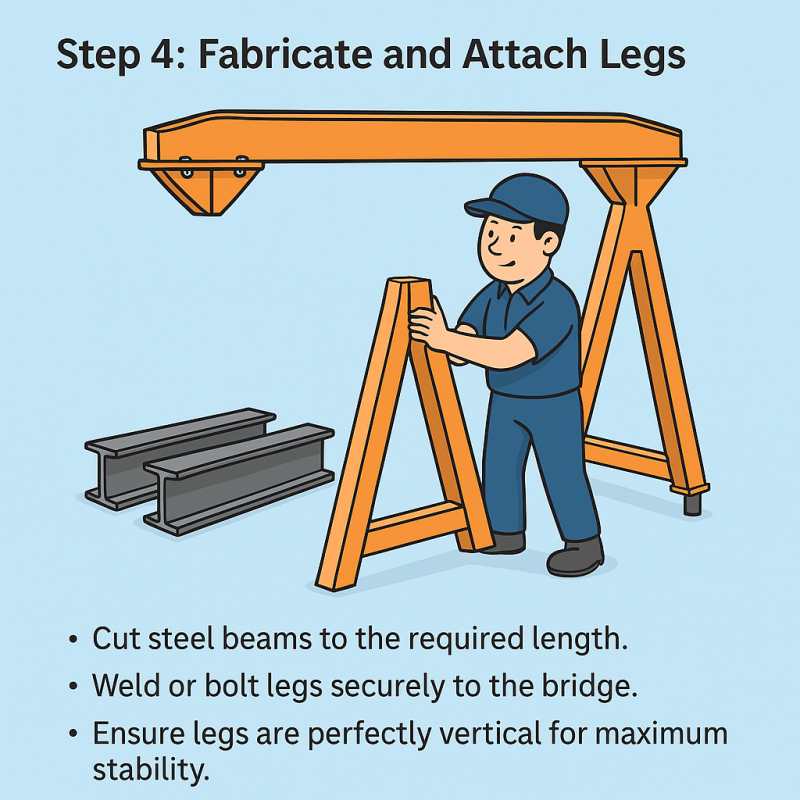

The legs support the bridge and must be sturdy enough to handle operational loads:

- Cut steel beams to the required length.

- Weld or bolt legs securely to the bridge.

- Ensure legs are perfectly vertical for maximum stability.

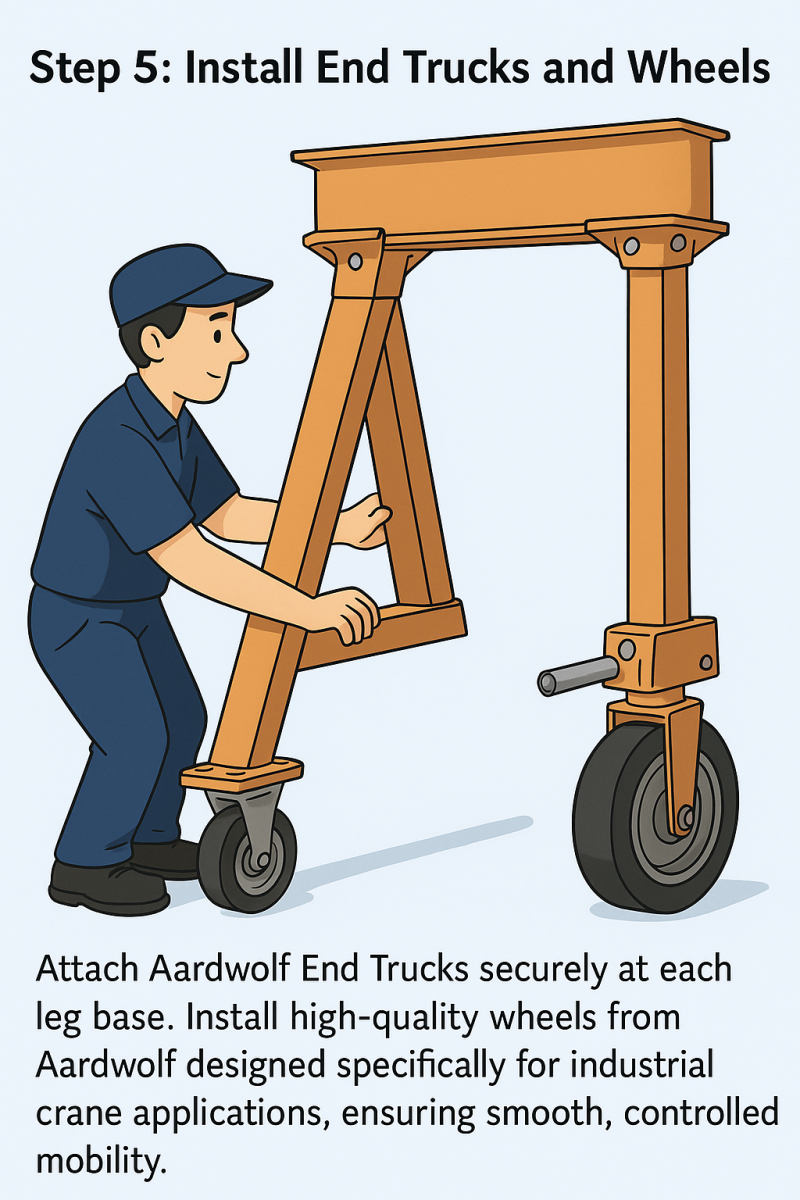

End trucks support crane movement:

- Attach Aardwolf End Trucks securely at each leg base.

- Install high-quality wheels from Aardwolf designed specifically for industrial crane applications, ensuring smooth, controlled mobility.

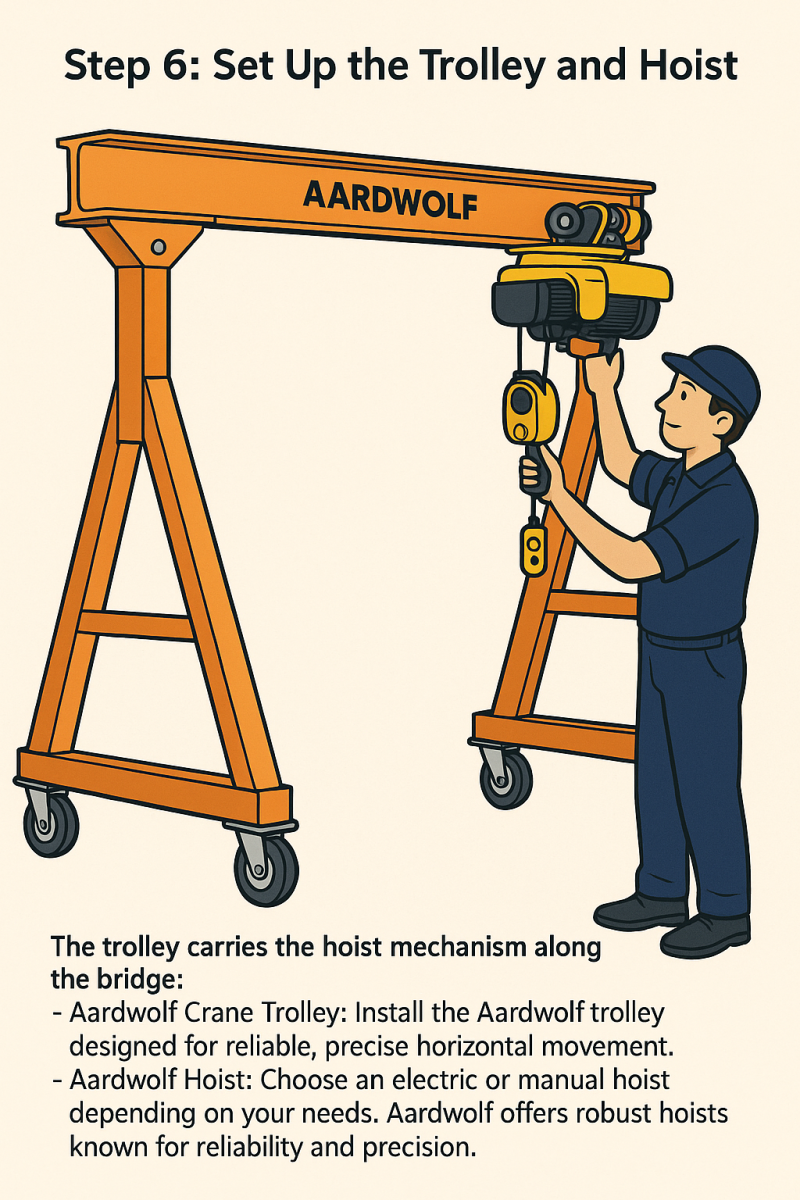

The trolley carries the hoist mechanism along the bridge:

- Aardwolf Crane Trolley: Install the Aardwolf trolley designed for reliable, precise horizontal movement.

- Aardwolf Hoist: Choose an electric or manual hoist depending on your needs. Aardwolf offers robust hoists known for reliability and precision.

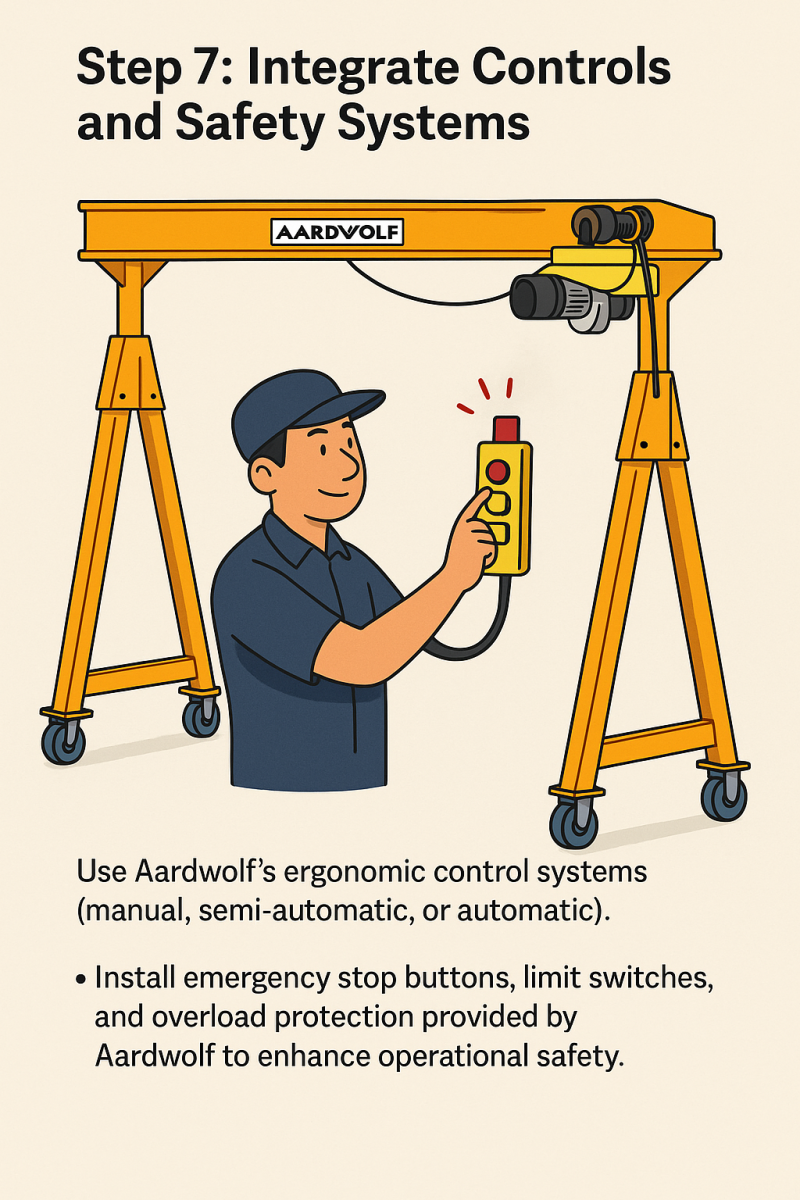

Effective controls and safety systems are critical:

- Use Aardwolf’s ergonomic control systems (manual, semi-automatic, or automatic).

- Install emergency stop buttons, limit switches, and overload protection provided by Aardwolf to enhance operational safety.

Exceptional Durability and Reliability

- Precision and Ease of Operation

- Customization

Proper maintenance and safety are essential to maximize your gantry crane’s lifespan and ensure safe operations.

Incorporating future-oriented Aardwolf products ensures your gantry crane remains functional and efficient over the long term.

Building a gantry crane involves strategic planning, precise construction, and the selection of quality components. Utilizing Aardwolf’s industry-leading products ensures your crane not only meets but exceeds performance expectations.

References

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

11. Powered counterbalance Crane

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.