With the integration of smart technologies, freestanding jib cranes, wall mounted jib cranes, ceiling mounted jib cranes, articulating jib cranes, and pillar jib cranes are evolving to support more efficient, safe, and data-driven operations. In today's industrial landscape, automation is no longer optional—it’s essential.

If you’re new to these systems, begin by exploring What is a jib crane? to understand the fundamentals before diving into their automated applications.

Automated jib cranes offer enhanced performance in industrial settings by enabling:

Automation isn’t just about reducing manual labor—it’s about enhancing accuracy, safety, and uptime.

To learn more about upcoming innovations, visit Industrial jib cranes in the future.

Freestanding jib cranes are often found in warehouses, workshops, and loading areas. Their 360-degree rotation and high load capacity make them ideal for automation.

These setups are especially useful in manufacturing environments with high-volume, repetitive tasks.

A wall mounted jib crane is perfect for confined workspaces, mounted to structural columns or walls.

To understand this crane type’s physical design better, check out How a Jib Crane works?.

For operations that require complete floor space utilization, ceiling mounted jib cranes offer unmatched efficiency.

These are ideal in cleanroom environments or assembly lines where spatial efficiency is critical.

Articulating jib cranes are among the most versatile for automation due to their dual-arm pivoting capability, which allows them to maneuver around obstacles.

Their smart movement features reduce the need for multiple lifting points and streamline complex operations.

Explore practical operation tips in How to operate a jib crane.

Pillar jib cranes, similar to freestanding cranes but more compact, are suited for fixed stations.

Their low-profile structure makes them ideal for automation in environments with limited vertical clearance.

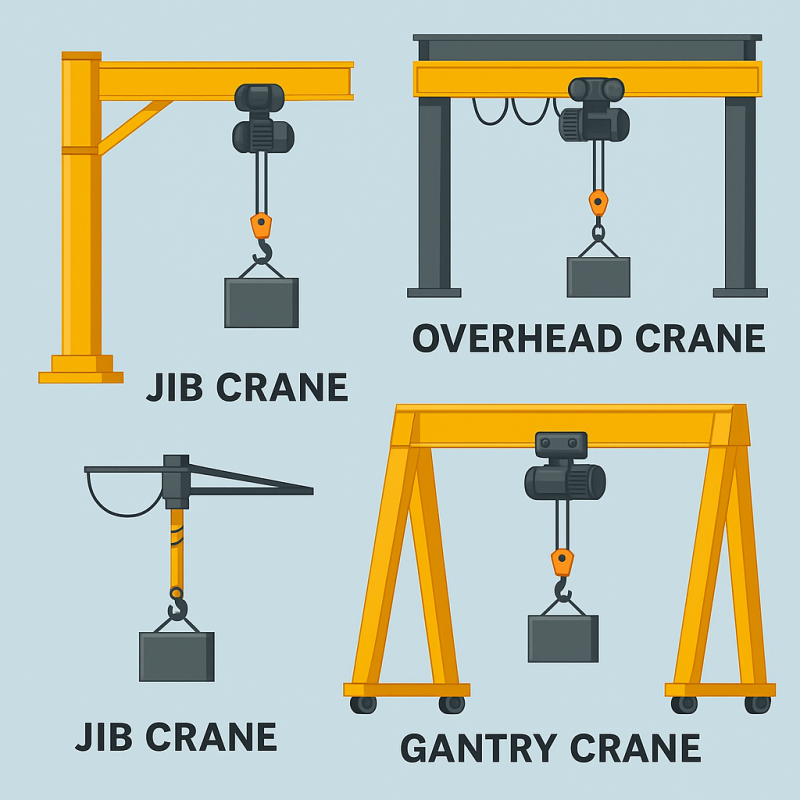

When choosing between jib cranes and overhead crane systems, automation capability is a critical factor.

| Feature | Jib Cranes | Overhead Cranes |

|---|---|---|

| Automation Readiness | High (especially wall/ceiling-mounted) | High, but more complex integration |

| Footprint | Small to medium | Large |

| Load Range | Light to medium | Medium to heavy |

| Flexibility | High (esp. articulating) | Moderate |

| Installation Cost | Lower | Higher |

See full comparison at Jib cranes vs overhead cranes systems.

Installation success hinges on following proper procedures—learn more in What is a crane application.

Application: Articulating jib cranes automatically position tooling and parts.

Impact: Reduced operator strain and higher throughput.

Application: Ceiling-mounted jib cranes perform automated part transfer in cleanrooms.

Impact: Minimal contamination risk and enhanced spatial efficiency.

Application: Pillar-mounted cranes deliver parts from inventory to work bays.

Impact: Faster turnaround times and optimized part access.

To remain competitive, businesses should:

Learn what’s coming next in Industrial jib cranes in the future.

Automation in jib cranes is no longer a concept for the future—it’s happening now. From freestanding and articulating jib cranes to ceiling-mounted and pillar cranes, each type offers unique opportunities for process enhancement. By integrating automation into your jib crane systems, you can elevate precision, reduce operational costs, and improve workplace safety.

Begin your transformation by understanding What is a jib crane? and explore how these systems fit into your broader automation strategy.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.