Among the most popular options are jib cranes, gantry cranes, and hoists. Each system offers unique strengths depending on your facility layout, weight capacity, and lifting frequency.

If you’ve ever asked yourself, “What is a jib on a crane?”, start with this quick overview of how they work and when they shine best in industrial environments. You can explore more here: what is a jib on a crane.

Let’s explore how jib cranes stack up against hoists and gantry cranes, helping you make the most practical and cost-effective choice for your lifting needs.

Jib cranes are fixed-position cranes with a horizontal arm (jib or boom) that supports a hoist for lifting and moving loads. They're especially valued for their ability to serve localized areas efficiently and can be wall-mounted, floor-mounted, or ceiling-suspended.

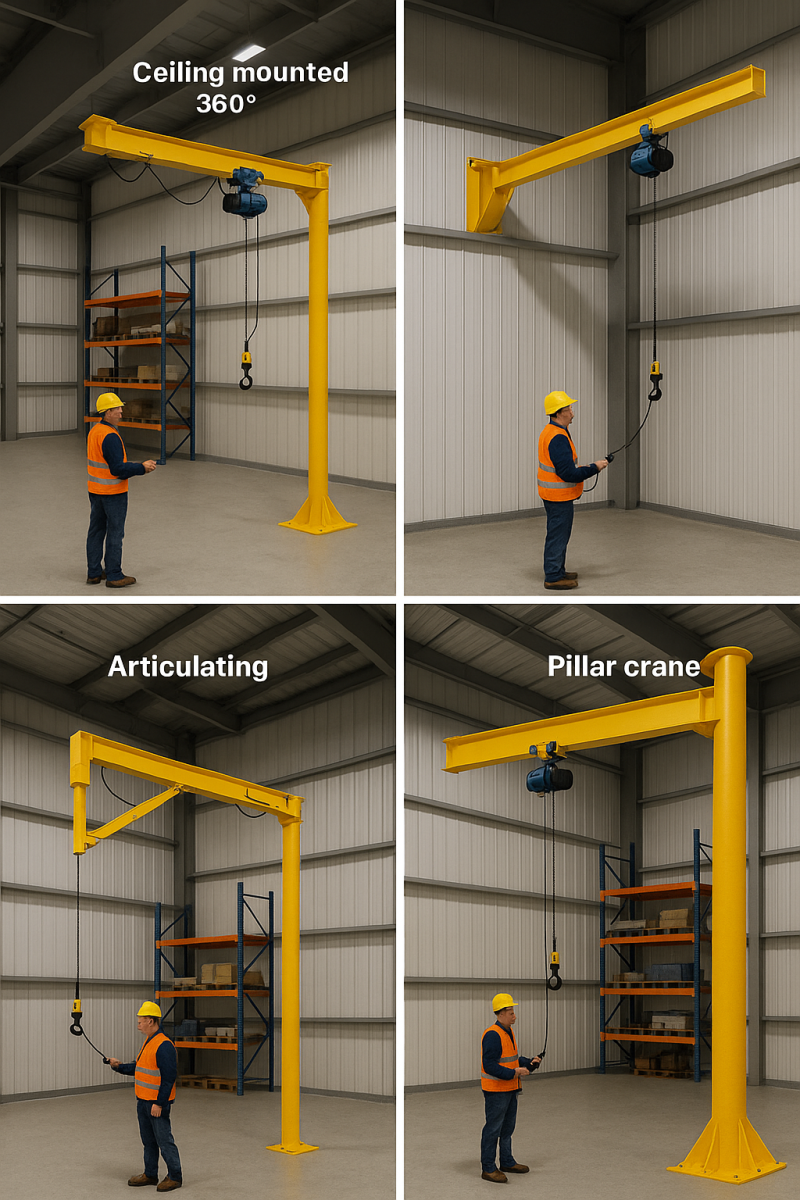

Common types of jib cranes include:

Freestanding Jib Crane – Mounted on the floor with full 360° rotation and high capacity.

Wall Mounted Jib Crane – Saves space by attaching to structural walls or columns.

Ceiling Mounted Jib Crane – Offers overhead reach without floor interference.

Articulating Jib Crane – Features multiple pivot points for navigating around obstacles.

Pillar Jib Crane – Compact and used in workstations for light-duty tasks.

You can learn more about their industrial roles here: what is a jib on a crane used for.

Gantry cranes are mobile structures supported by legs that move on wheels or rails. They are often used for lifting large, heavy materials in open or temporary spaces like shipping yards, construction sites, and some manufacturing floors.

Strengths of Gantry Cranes:

Very high lifting capacities

Portable and adjustable in size

Don’t require building modifications

Limitations:

Large footprint required

More expensive to move and maintain

Not ideal for confined indoor workstations

Hoists are simple lifting devices that raise and lower loads using ropes or chains. They’re commonly used as components in crane systems—but they can also be mounted to fixed overhead tracks or trolleys.

Strengths of Hoists:

Low-cost solution for vertical lifting

Easy to install and operate

Ideal for occasional or low-weight lifting

Limitations:

No horizontal movement unless paired with a trolley or crane

Limited load capacity

Often slower in production environments

| Feature | Jib Cranes | Gantry Cranes |

|---|---|---|

| Mobility | Fixed (except articulating) | Mobile via wheels or track |

| Footprint | Compact, space-saving | Requires large operating area |

| Installation | Wall, floor, or ceiling-mounted | No mounting required, but needs rail system |

| Load Capacity | Light to medium (up to 5 tons typical) | Medium to heavy (up to 100+ tons possible) |

| Precision | High – especially with articulating arms | Moderate – better for bulk load handling |

| Maintenance | Low | Moderate to high |

Want more technical insight? See this guide: Jib cranes vs overhead cranes solutions

Choose a jib crane if your workspace is:

Confined and needs localized lifting support

Not suitable for rail or floor-mounted gantry systems

Focused on precision placement of parts or equipment

Geared for repetitive lifting tasks near workstations

A freestanding jib crane provides wide-area coverage for assembly lines, while a wall mounted jib crane can free up floor space in fabrication shops.

Explore installation steps here: how to level a jib crane

Unlike hoists and gantry systems, jib cranes integrate well with automation and IoT for modern factory environments.

With options like motorized trolleys, programmable lifting, and smart sensors, articulating jib cranes stand out for complex handling where obstacles or machinery might block traditional straight-arm movement.

Need to see one in action? Review how to operate a jib crane

Jib cranes are typically fabricated from heavy-duty steel, with base anchoring requirements depending on type:

Freestanding models need reinforced concrete pads

Wall-mounted versions require a structural wall or column

Ceiling-mounted options must anchor to load-bearing beams

When designing or sourcing a custom model, consider:

Reach (arm length)

Load rating (1–5 tons is typical)

Rotation (180°–360°)

Clearance height

Looking to customize your own? Learn how to build a jib crane with the right specs.

| System | Initial Cost | Maintenance Cost | Space Required | Automation Compatible |

|---|---|---|---|---|

| Jib Cranes | $$ | Low | Low–Moderate | Yes |

| Gantry Cranes | $$$$ | Medium–High | High | Partial |

| Hoists | $ | Low | Minimal | No |

If you're still unsure whether to choose jib cranes, gantry cranes, or basic hoists—ask yourself:

Do you need localized, repetitive lifting?

Are space constraints an issue?

Do you need horizontal movement in a fixed arc?

Is precision placement important?

If the answer is “yes” to any of these, then a jib crane is likely your best fit.

For an all-in-one lifting solution with safety, precision, and scalability, jib cranes deliver a powerful balance of cost-efficiency and performance.

Still on the fence? Start with what is a jib on a crane or dive into use cases with what is a jib on a crane used for.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.