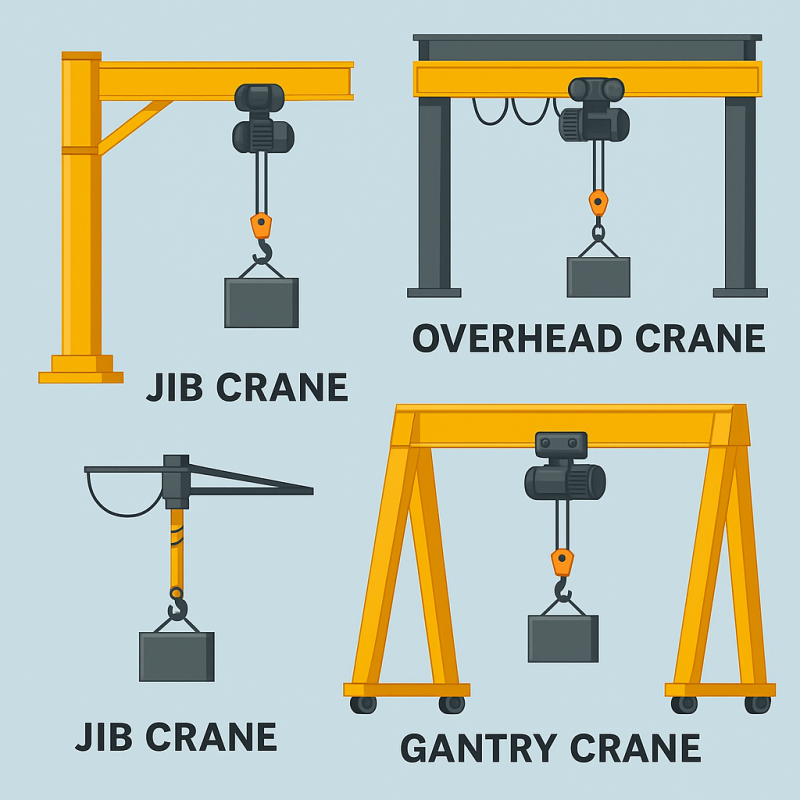

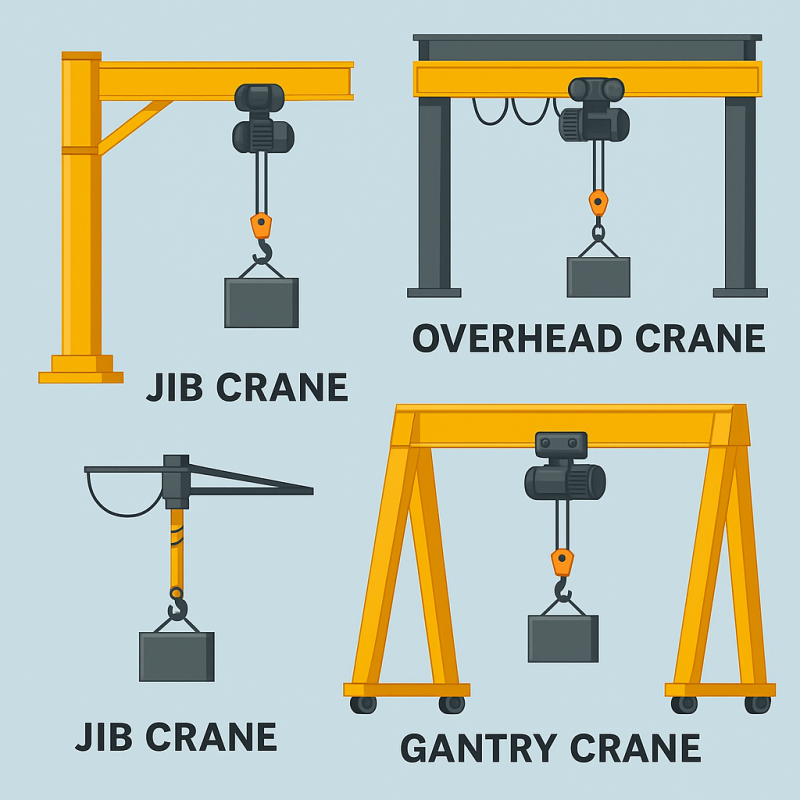

Among popular lifting solutions are jib cranes, gantry cranes, and overhead cranes—each with distinct benefits and ideal use scenarios. Understanding their differences is crucial to select the optimal solution for your business.

This guide deeply compares these three lifting solutions, focusing extensively on jib cranes, including types such as freestanding jib cranes, wall-mounted jib cranes, ceiling-mounted jib cranes, articulating jib cranes, and pillar jib cranes.

Stay informed about modern crane systems by reviewing the latest Jib Cranes Trends.

Understanding Jib Cranes: Types and Benefits

What Are Jib Cranes?

Jib cranes are compact, efficient lifting devices consisting of a horizontal boom (jib) attached to a vertical support structure. This structure allows radial movement and precise positioning of loads within a specific work area.

Jib cranes come in several key configurations:

- Freestanding Jib Crane: Mounted independently on concrete foundations, offering 360° rotation, suitable for extensive workspace coverage.

- Wall-mounted Jib Crane: Attached to walls or structural columns, providing limited (typically 180°–200°) rotation. Ideal where floor space is limited.

- Ceiling-mounted Jib Crane: Suspended from overhead beams, perfect for freeing floor space and integrating with existing workflow setups.

- Articulating Jib Crane: Equipped with multiple pivot points, highly flexible, and excellent for tight, obstacle-rich environments.

- Pillar Jib Crane: Floor-mounted with moderate rotation, optimal for medium-duty tasks near machinery or workstations.

For detailed crane specifications and features, explore the Smart Jib Cranes.

Overview of Gantry and Overhead Cranes

Gantry Cranes

Gantry cranes feature a hoist mounted on a horizontal beam, supported by vertical legs on wheels or tracks. They provide considerable mobility and are ideal for indoor and outdoor applications requiring significant load movement.

Overhead Cranes

Overhead cranes (also known as bridge cranes) have their lifting mechanism traveling on a bridge structure along elevated runways. They excel in lifting heavy loads across large facilities, enhancing operational efficiency in manufacturing and assembly plants.

Key Differences: Jib Cranes vs. Gantry & Overhead Cranes

Coverage and Mobility

- Jib Cranes: Provide precise localized lifting within a limited radius, usually up to a few meters around their pivot point. They are stationary, though articulating models offer increased flexibility.

- Gantry Cranes: Offer significant mobility over large areas, ideal for tasks requiring heavy-duty portability across fixed rails or freely movable wheels.

- Overhead Cranes: Operate along fixed runways overhead, providing extensive, comprehensive facility coverage.

Load Capacity and Applications

- Jib Cranes: Ideal for moderate load capacities (up to several tons), suitable for assembly stations, loading bays, or machinery servicing areas.

- Gantry Cranes: Suitable for heavier loads, particularly in warehouses, docks, or large manufacturing areas.

- Overhead Cranes: Handle very heavy loads and large materials, making them essential in steel mills, large-scale manufacturing, and automotive factories.

Pros and Cons of Using Jib Cranes

Advantages

- Cost-effective and quick to install.

- Minimal floor space required, especially ceiling-mounted or wall-mounted versions.

- Exceptional flexibility and precision in tight workstations.

- Low maintenance compared to gantry and overhead cranes.

- Increasingly available as Smart Jib Cranes, incorporating automated features for enhanced safety and productivity.

Disadvantages

- Limited load capacity and restricted radius coverage.

- Fixed installation limits their flexibility across large facility areas.

Pros and Cons of Using Gantry and Overhead Cranes

Advantages

- Higher load capacities and greater coverage areas.

- Mobility (gantry cranes) and comprehensive overhead operation (overhead cranes).

- Excellent for large, bulky, or heavy load transfers.

Disadvantages

- Higher installation costs and longer setup periods.

- Complex structural requirements (especially overhead cranes).

- More intensive maintenance needs, including regular inspections of runway rails and mechanical systems.

How to Apply Jib Cranes in Your Facility

Integrating jib cranes effectively requires understanding operational needs and work patterns:

- Evaluate Workspace: Choose wall-mounted jib cranes where floor space is premium, freestanding cranes for heavier tasks, or articulating cranes to navigate obstacles.

- Select Appropriate Capacity: Match load handling capabilities precisely with your regular operations.

- Leverage Smart Technologies: Employ smart control systems for enhanced precision, efficiency, and safety.

Gain deeper insights into practical usage through How to apply Jib Cranes system.

Leveraging the Benefits of Smart Jib Cranes

Modern jib cranes increasingly integrate smart technologies, bringing notable advantages:

- IoT-enabled sensors for predictive maintenance.

- Automated and remote controls for improved accuracy and operator safety.

- Enhanced productivity through minimized downtime.

Understand these advancements further at Benefits of Smart Jib Crane.

Practical Design Considerations for Wall-Mounted Jib Cranes

Proper design is crucial for optimal operation:

- Confirm structural integrity of walls or columns.

- Carefully calculate required jib length and rotation limits.

- Select hoists and trolleys suited to the load types and lifting frequency.

Explore detailed guidance in How to design a Wall-mounted Jib Crane?.

Real-World Applications and Successes

Jib cranes are widely used due to their practical versatility:

- Articulating jib cranes excel in automotive workshops and assembly lines.

- Freestanding jib cranes handle tasks efficiently in open factory floors or shipping docks.

- Ceiling-mounted jib cranes optimize workflows in high-density production and cleanroom environments.

Discover specific operational successes at Jib Cranes works.

Conclusion

Choosing between jib cranes, gantry cranes, and overhead cranes hinges on your specific operational needs. Jib cranes offer unmatched localized lifting precision and cost-effectiveness, while gantry and overhead cranes provide comprehensive, high-capacity material handling.

By carefully evaluating your workspace, load requirements, flexibility, and budget, you can select the ideal lifting system. Stay updated with evolving industry standards and crane innovations by following Jib Cranes Trends, and invest strategically to maximize productivity and operational efficiency.

References

1. How to operate a Jib Cranes safely

2. What is a Jib Crane?

3. Over brace jib crane wall mounted

4. Wall mounted Jib Crane

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

7. Where is Jib Crane used?

8. Manual Counterbalance Crane

9. Floor Mounted Jib Crane

10. Over Braced Jib Crane Column Mounted

11. Powered counterbalance Crane

12. Portable Gantry Crane