While traditionally manual, jib cranes are increasingly being adapted to automation, revolutionizing workplace productivity and safety. This article dives deep into how various types of jib cranes—including freestanding jib cranes, wall mounted jib cranes, ceiling mounted jib cranes, articulating jib cranes, and pillar jib cranes—are evolving through automation.

Stay ahead of industry advancements by exploring Smart Jib Cranes.

Before delving into automation, it’s essential to understand the foundational operation of jib cranes. A jib crane typically comprises a horizontal boom (jib) connected to a vertical mast or support structure, with a hoist that moves along the jib's length, providing efficient radial load movement.

To fully appreciate these systems' evolution, explore in-depth details on How Jib Cranes work.

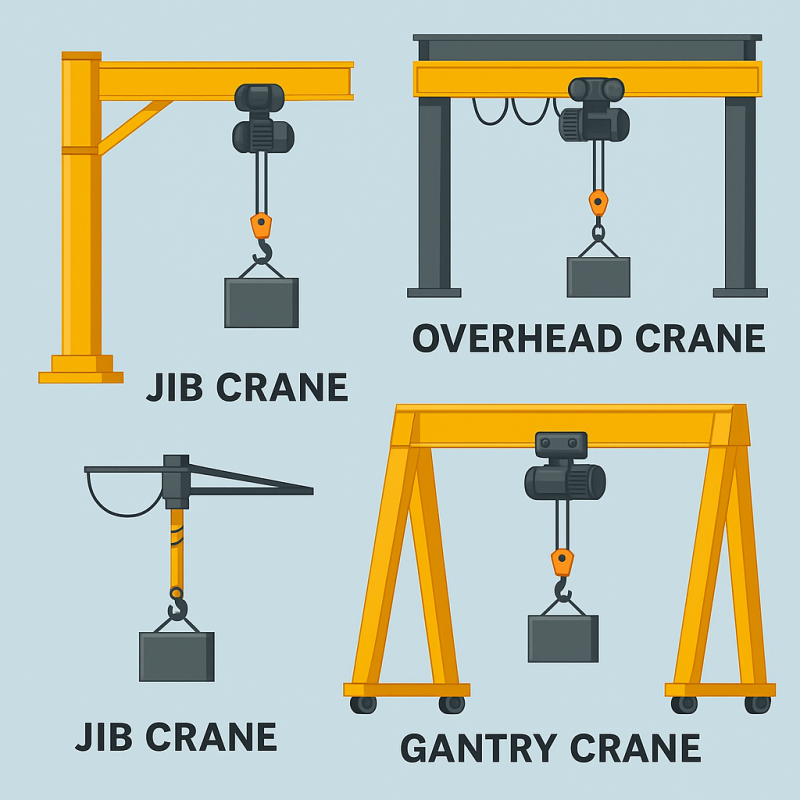

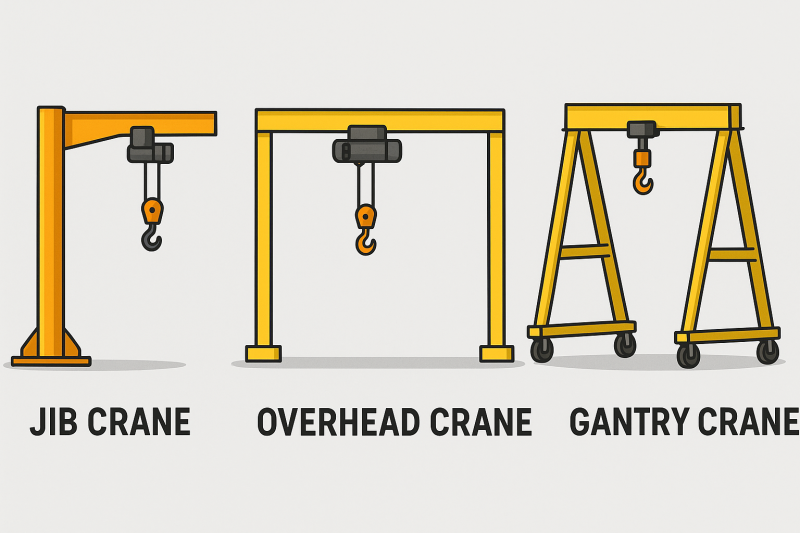

Jib cranes come in several configurations, each suited to particular industrial scenarios:

Freestanding Jib Crane: Offers a full 360-degree rotation, usually mounted on reinforced concrete foundations.

Wall Mounted Jib Crane: Attached directly to structural walls or columns, providing limited rotation but space-saving benefits.

Ceiling Mounted Jib Crane: Suspended from overhead structures, excellent for maximizing floor space.

Articulating Jib Crane: Features multiple pivot points for precise maneuvering in complex workspaces.

Pillar Jib Crane: Column-mounted, providing moderate rotation and compact installation ideal for maintenance areas.

Automation in industrial equipment is not new, but its integration into jib crane operations represents a significant leap forward. Automated jib cranes now include features such as IoT-enabled sensors, programmable logic controllers (PLCs), and advanced software for remote operation and precision movements.

This automation offers several substantial operational benefits, detailed further in Benefits of Smart Jib Crane Technology.

Enhanced Safety: Automated systems reduce the likelihood of human errors, providing safer operations.

Increased Efficiency: Precise automated controls minimize downtime and optimize material handling.

Reduced Operational Costs: Automation reduces manual labor requirements, enhancing cost-efficiency in the long run.

Improved Accuracy: Automated positioning allows for exact placement and handling of delicate or heavy materials.

Each type of jib crane adapts differently to automation technology based on their design, usage, and operational needs.

Freestanding jib cranes, with their sturdy, independent design and 360-degree coverage, are particularly suited for advanced automation. Automated freestanding jib cranes typically feature motorized rotation, programmable hoists, and sensors that ensure precise load handling, making them perfect for large manufacturing environments or shipping docks.

Automation Benefits: Enhanced load management, faster processing times, and integration into larger automated handling systems.

Explore the latest advancements by reviewing current Jib Cranes Trends.

Wall mounted jib cranes, known for their compact footprint and operational efficiency, adapt well to automation in confined workspaces. Automated wall-mounted cranes include precision motorized controls, limit switches, and remote operation features. These enhancements increase productivity by enabling consistent and repetitive load handling.

Automation Benefits: Precise load placement in tight environments, reduced manual input, and optimized workstation workflows.

Discover practical examples by visiting Explore a Wall-mounted Jib Crane?.

Ceiling-mounted jib cranes, already efficient in terms of space utilization, significantly benefit from automation. Integration of automated trolleys and hoists controlled remotely or via pre-programmed routes enhances material flow, particularly in sensitive areas like clean rooms or electronic assembly lines.

Automation Benefits: Streamlined workflows, optimized space utilization, and reduced contamination risks through minimal human interaction.

Articulating jib cranes, uniquely flexible due to their dual-arm pivots, achieve substantial productivity gains through automation. These cranes' automation typically includes computerized control systems enabling precise and repeatable movements, essential in intricate assembly or maintenance tasks.

Automation Benefits: Superior maneuverability, reduced operator fatigue, and highly accurate placement even in cluttered spaces.

Learn more operational specifics in How Jib Cranes work.

Automation in pillar jib cranes usually involves moderate yet impactful technological additions, such as motorized slewing and lifting controls. Given their compact and straightforward operation, pillar jib cranes readily adapt to automation, enhancing productivity and ergonomics for operators in repetitive task environments.

Automation Benefits: Improved safety, consistent material handling, and reduced downtime for repetitive lifting operations.

Successfully integrating automation with jib cranes requires a systematic approach:

Assess Operational Requirements: Clearly define what you aim to achieve through automation—whether safety improvements, precision tasks, or increased throughput.

Select Appropriate Crane Type and Automation Level: Match your workspace constraints, load handling, and operational needs with the right jib crane configuration.

Proper Installation: Follow detailed, step-by-step guidance on How to install Jib Cranes system.

Training and Support: Ensure thorough operator training for automated features and schedule regular maintenance to maintain peak efficiency.

As automation technologies evolve, the role and capabilities of jib cranes expand significantly. From basic lifting tools, jib cranes have become sophisticated, smart devices, central to achieving optimal operational efficiency. Whether choosing a freestanding, wall-mounted, or articulating jib crane, automation ensures improved safety, greater precision, and reduced operational costs.

Embrace the transformative possibilities of automation by exploring more about Smart Jib Cranes and remain ahead in your industry's operational standards.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.