Among the most effective tools to enhance material handling and streamline workflows are jib cranes. Compact, flexible, and highly customizable, jib cranes come in various configurations to suit specific industrial requirements. This article will guide you through the foundational basics, essential specifications, and practical applications of jib cranes—including popular variants like freestanding jib cranes, wall mounted jib cranes, ceiling mounted jib cranes, articulating jib cranes, and pillar jib cranes.

Stay informed about evolving industry standards by reviewing the latest Jib Cranes Trends.

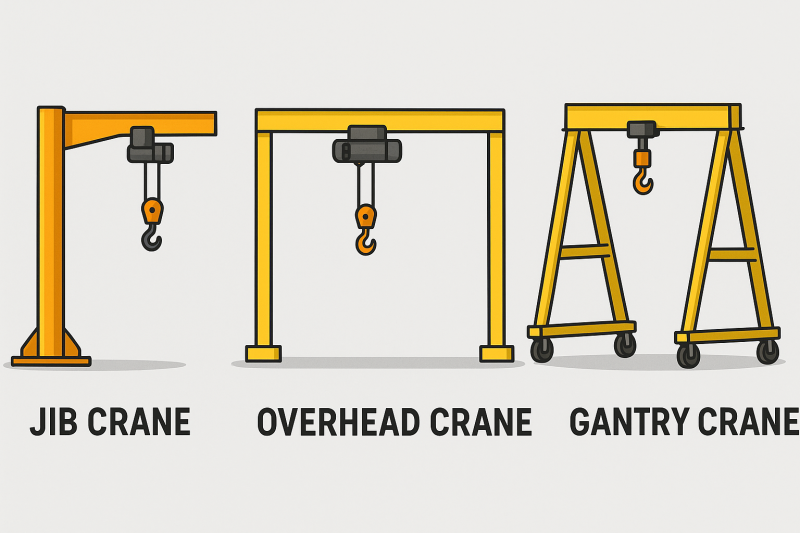

Jib cranes are specialized lifting devices featuring a horizontal arm (jib or boom) supporting a movable hoist. The jib rotates around a pivot point, allowing efficient radial load handling within a specific area. Understanding these cranes' fundamental characteristics and types is essential for effective application in your workspace.

Every jib crane consists of several vital components:

Jib Arm: Horizontal beam that carries the load.

Hoist and Trolley: Devices that lift and move loads horizontally along the jib.

Pivot Point (Mounting Structure): Supports the jib, allowing rotation.

Foundation or Support Structure: Ensures stability and safety under load.

Knowing these components helps operators appreciate how precisely Jib Cranes works.

A freestanding jib crane is independently mounted onto a concrete foundation, providing full 360-degree rotation. They are ideal for open workspaces or outdoor settings requiring extensive radial coverage.

Ideal Uses: Manufacturing floors, shipping docks, fabrication workshops.

Pros:

Maximum rotation coverage (360°).

Supports heavier loads.

Independent structural installation.

Cons:

Requires significant floor space and solid foundations.

A wall mounted jib crane is attached directly to walls or structural columns, offering approximately 180–200 degrees of rotation. They efficiently utilize vertical space, ideal for tight areas.

Understand its design considerations thoroughly in How to design a Wall-mounted Jib Crane?.

Ideal Uses: Machine shops, assembly lines, small workstations.

Pros:

Space-efficient, minimal footprint.

Easy installation.

Cons:

Limited rotation and load capacity compared to freestanding types.

Suspended from overhead beams or trusses, the ceiling mounted jib crane maximizes floor space, allowing unobstructed movement below.

Ideal Uses: Clean rooms, laboratories, precision assembly lines.

Pros:

Frees floor space entirely.

Efficient for confined spaces.

Cons:

Limited load capacity due to structural constraints of ceilings.

An articulating jib crane is equipped with multiple pivot points, offering high maneuverability around obstacles and tight spaces. This type is particularly beneficial in crowded or complex work environments.

Learn more specifics on articulating cranes at Jib Cranes works.

Ideal Uses: Automotive workshops, precision assembly lines, CNC machining cells.

Pros:

High flexibility and maneuverability.

Excellent for intricate tasks.

Cons:

Typically lower load capacities.

A pillar jib crane is similar to freestanding cranes but uses a column-mounted system bolted to the floor. These cranes typically provide partial rotation, suitable for medium-duty applications.

Ideal Uses: Maintenance stations, assembly workstations, small production cells.

Pros:

Quick installation, moderate load capacity.

Space-saving vertical design.

Cons:

Less rotation coverage than freestanding variants.

Selecting the right jib crane involves understanding several critical specifications:

Load Capacity: Maximum load the crane can safely handle.

Rotation Range: Degree of rotation (180°, 270°, or full 360°).

Jib Length (Reach): Distance from pivot to end of jib; defines workspace coverage.

Mounting Method: Floor, wall, or ceiling-mounted systems.

Power Source and Controls: Manual, electric, or automated controls and hoists.

To explore advanced specifications and technology, delve into Smart Jib Cranes.

Proper installation and use are critical for maximizing jib crane benefits:

Evaluate Workspace Needs: Clearly define load handling tasks, rotation needs, and available mounting surfaces.

Choose the Appropriate Crane Type: Freestanding for heavy-duty loads, wall-mounted for compact spaces, articulating for precision tasks.

Training Operators: Ensure operators understand jib crane functionalities, limits, and safety procedures.

Detailed guidance can be found in How to apply Jib Cranes system.

Modern smart jib cranes include advanced sensors, automation, and IoT capabilities, offering considerable operational benefits:

Increased Safety: Automated alerts and remote operation reduce workplace accidents.

Enhanced Productivity: Reduced downtime through predictive maintenance and optimized load handling.

Improved Precision: Automated positioning and controlled movements increase efficiency and accuracy.

Explore further advantages at Benefits of Smart Jib Crane.

The installation foundation significantly influences jib crane performance and safety:

Concrete Footings: Essential for freestanding and pillar cranes, ensure adequate strength and depth.

Structural Walls/Columns: Must withstand dynamic loads for wall-mounted cranes.

Ceiling Structures: Verify load-bearing capacities before installing ceiling-mounted cranes.

For expert solutions, visit Jib Cranes works.

Understanding the fundamental basics and specifications of jib cranes empowers businesses to enhance productivity, safety, and space utilization effectively. Whether opting for a robust freestanding jib crane or a versatile articulating model, informed choices ensure maximum operational benefits.

Stay updated on advanced solutions, emerging technologies, and Jib Cranes Trends, helping you maintain competitiveness and efficiency.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.