To choose, install, or maintain them effectively, you must understand their core structural components—from the boom and mast to the base and hoisting mechanisms. Whether it's a freestanding jib crane, a wall mounted jib crane, or an articulating jib crane, each model has unique structural demands.

If you’re unsure about the fundamentals, first explore what is a jib on a crane.

Failing to understand the structural composition of your jib crane can lead to:

Incorrect load distribution

Premature wear on bearings or anchor points

Safety violations

Excessive boom deflection

Knowing the specific use of structural components also helps you identify what crane best fits your operational needs. Learn more about what is a jib on a crane used for.

Purpose: The horizontal beam supporting the trolley and hoist.

Structure: Usually an I-beam or enclosed track made from high-tensile steel.

Variations:

Straight booms in freestanding and wall-mounted cranes

Dual-jointed booms in articulating jib cranes for flexible reach

Key concern: Excessive deflection under load

Purpose: Vertical support holding the boom.

Used in:

Freestanding jib cranes with floor-mounted columns

Pillar jib cranes for workstation use

Wall and ceiling-mounted cranes may connect directly to structural elements without needing a mast.

Purpose: Transfers crane loads to the floor or structure.

Types:

Concrete baseplate for freestanding cranes

Anchor bolts or wall brackets for wall-mounted cranes

Ceiling mounting kits for overhead integration

Important for: Leveling and long-term stability

Hoist: Performs the vertical lifting and can be electric, pneumatic, or manual.

Trolley: Moves horizontally along the boom; available in push-type or motorized versions.

Bearing Assembly: Located at the mast-boom junction for smooth movement.

Rotation Range:

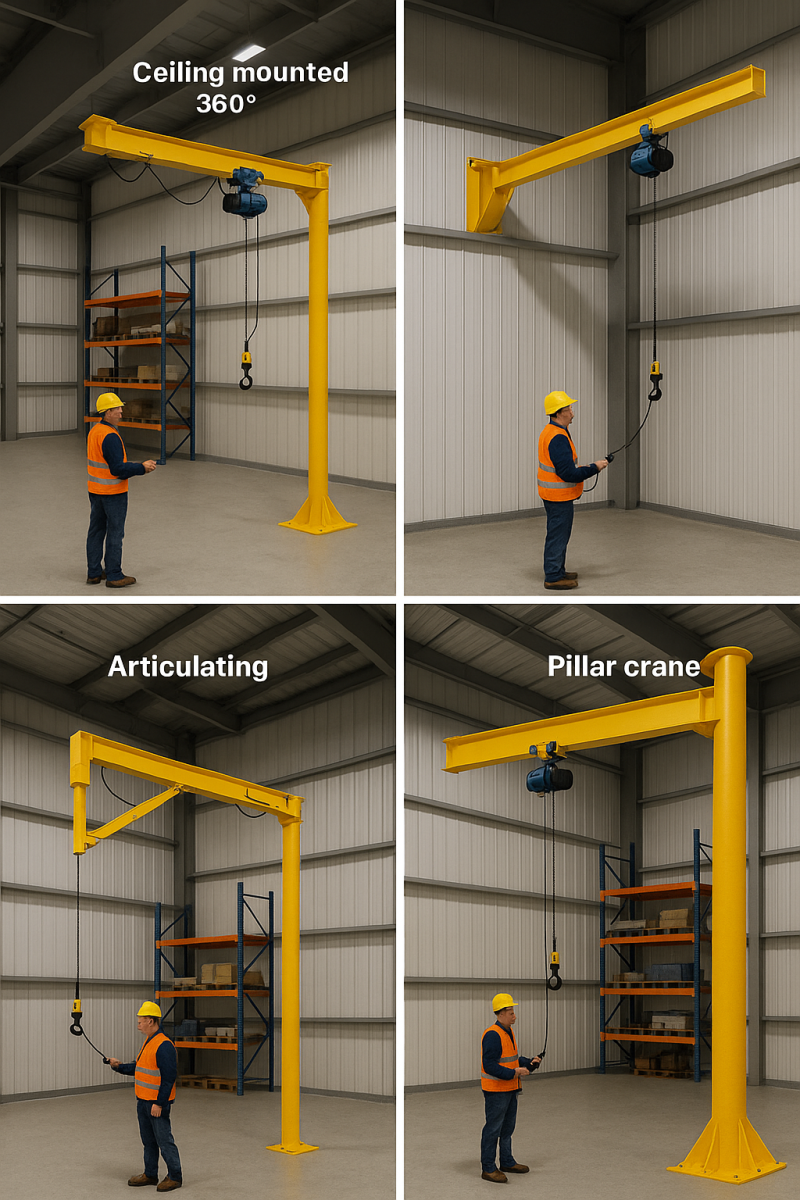

Wall-mounted: 180° to 200°

Freestanding: Full 360° rotation

Maintenance Tip: Lubricate regularly for efficient operation.

For more: how to operate a jib crane

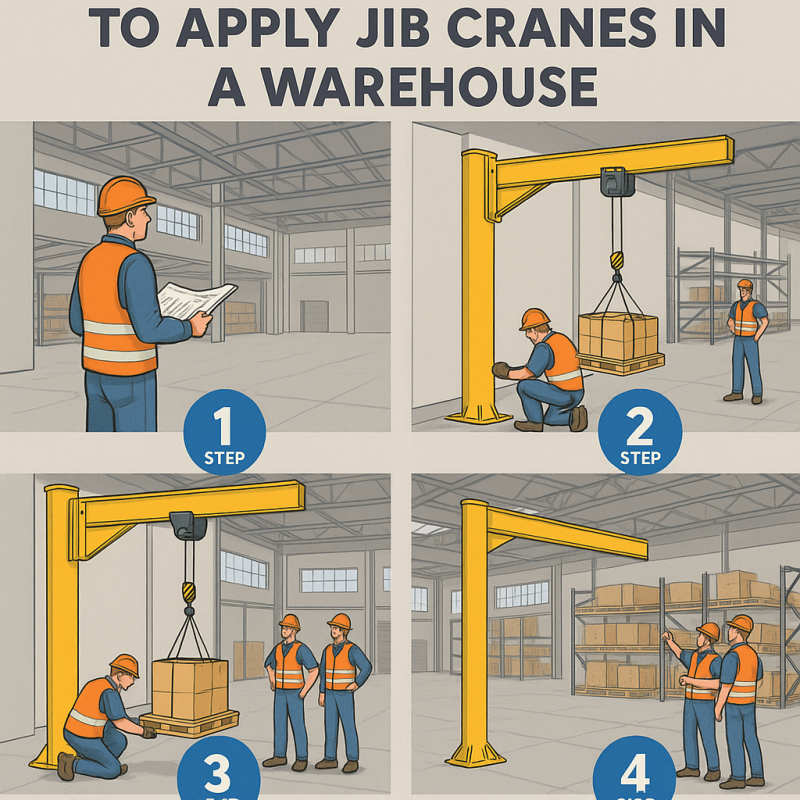

Includes a mast and baseplate

Supports full 360° rotation

Ideal for heavy loads in open-floor environments

Bolts to load-bearing columns or building walls

No mast required

Ideal for tight interiors or facility retrofits

Suspended from structural beams

Maximizes floor space

Used in cleanrooms or assembly lines

Dual-arm pivoted boom design

Ideal for complex work zones with machinery obstructions

Requires precise bearing and arm alignment

Shorter mast mounted to shop floors or portable bases

Serves light-duty workstation applications

Often modular for flexibility

Mild Steel (A36): Standard for general-use cranes

High-Strength Steel (A572): Used in higher-load, longer-reach models

Surface Treatments: Galvanization or powder coating for corrosion protection

| Feature | Jib Cranes | Overhead Cranes |

|---|---|---|

| Mounting | Floor, wall, or ceiling | Roof-runway or suspended girders |

| Flexibility | High (esp. articulating types) | Limited to runway track |

| Load Range | Light to moderate | Moderate to very heavy |

| Installation Ease | Easier, localized | Requires structural infrastructure |

Explore this in Jib cranes vs overhead cranes solutions.

Use a spirit level or laser to align vertical mast

Cure anchor bolts fully before torqueing

Square mast with boom before operation

Learn exact steps from how to level a jib crane

Daily: Check for visible damage or misalignment

Monthly: Lubricate moving parts, tighten bolts

Quarterly: Test load under full arm reach to check deflection

Annually: Structural inspection by qualified personnel

The efficiency, safety, and longevity of jib cranes depend on proper structural design and maintenance. Whether you're working with a freestanding, wall mounted, articulating, or pillar jib crane, knowing how each component works will help you make better operational and purchasing decisions.

Looking to install or customize your crane? Explore how to build a jib crane for a real-world example and specifications.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.