No longer limited to simple lifting tasks, today’s jib cranes integrate advanced smart features—enhancing safety, efficiency, and control. But not all jib cranes offer the same level of automation or digital enhancement. The type of crane you choose plays a significant role in determining which features are available and most effective.

In this article, we’ll explore how smart functionalities differ across common jib crane types—including freestanding, wall mounted, ceiling mounted, articulating, and pillar jib cranes—to help you match the right solution to your operational goals.

To get started with hardware fundamentals, explore how to install jib cranes.

Every jib crane type is designed for a specific spatial environment and load handling need. For an in-depth review of the different crane types, visit this guide on jib crane specification.

Here’s a brief recap of the major types:

Freestanding Jib Crane: Mounted on the floor with a concrete foundation, offering 360° rotation and high load capacity.

Wall Mounted Jib Crane: Affixed to a building’s vertical structure; ideal for saving floor space.

Ceiling Mounted Jib Crane: Suspended from roof beams; maximizes floor clearance in compact areas.

Articulating Jib Crane: Features two pivot arms for maneuverability around obstacles.

Pillar Jib Crane: A vertical post-mounted design for workstations and light lifting.

While all these types fulfill the same basic lifting function, the smart technologies integrated into each can vary widely.

Modern jib cranes now come equipped with features like:

Load monitoring and overload prevention

Programmable movement patterns

IoT connectivity and data logging

Remote operation via touch panels or mobile devices

Collision avoidance and safety interlocks

Learn more about these smart enhancements in What are Key Smart Features in Automated Jib Cranes.

Let’s now explore how these features differ across crane types.

Freestanding jib cranes are most compatible with full smart integration due to their stability and 360-degree coverage.

Smart Capabilities:

Motorized slewing motion

Load sensors with real-time feedback

Integration with AGVs and WMS systems

Predictive maintenance alerts

Suitable for heavy-duty industrial use

Ideal For:

Factories with open space and high-capacity lifting needs.

Wall mounted cranes provide medium-range radial coverage without consuming floor space.

Smart Capabilities:

Programmable hoisting

Speed control and soft start features

Safety zoning (to avoid collision with machinery)

Moderate IoT functionality

Limitations:

May not support full 360-degree motion due to structural mounting.

Real-world integration: Explore how to apply a jib crane wall-mounted in industry for application details.

Suspended from overhead structures, these cranes keep floor space clear and integrate well into production lines.

Smart Capabilities:

Horizontal and vertical travel synchronization

Integration with PLCs for multi-zone control

Load balancing with adjacent cranes

Real-time diagnostics over network

Challenges:

Requires strong ceiling infrastructure for secure anchoring and motion stability.

This type features flexible pivoting arms, perfect for navigating obstructions or tight spaces.

Smart Capabilities:

Dual-axis motion control

Automatic repositioning

Advanced collision detection for arm joints

Touchscreen-controlled path planning

Use Cases:

Ideal for CNC machine loading, tool exchange, and robotic integration.

Interested in building one? Review specs and steps at jib crane application.

These cranes are generally used for low-capacity, high-frequency lifting within workstations.

Smart Capabilities:

Basic overload detection

Remote activation switches

Maintenance logs and cycle counters

Limitations:

Limited reach and movement radius; lower automation compatibility.

Choosing a smart crane is only the first step. The setup process plays a crucial role in ensuring all systems function correctly.

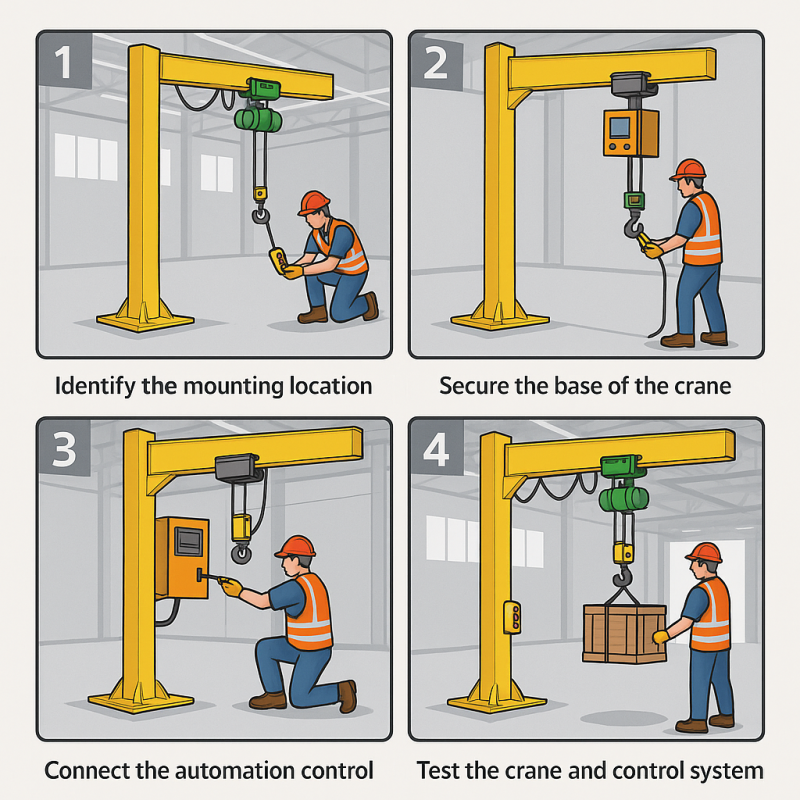

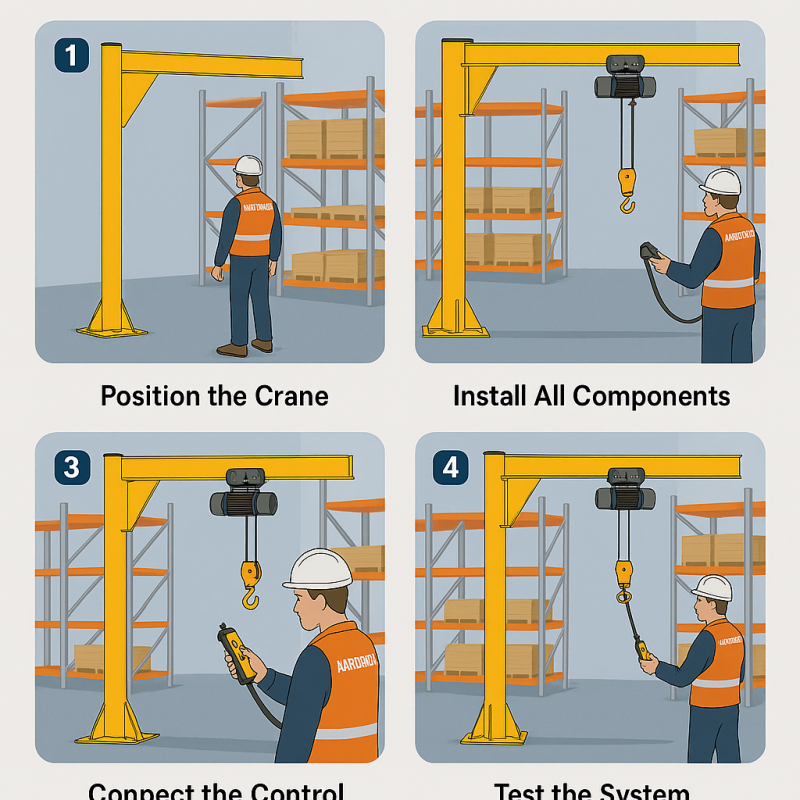

Installation Requirements:

Structural analysis for load-bearing components

Power and network connections for smart features

Safety programming (zone limits, alarms)

Operator interface configuration

Explore jib crane installation to review exact installation procedures for smart systems.

Not sure whether a jib crane is the right tool? Compare your options with bridge cranes, gantries, or hoist systems.

| Feature | Jib Cranes | Gantry Cranes / Overhead Cranes |

|---|---|---|

| Floor Space | Low to moderate | High |

| Mobility | Fixed or pivoting | Rail or mobile systems |

| Automation Compatibility | High for wall/ceiling/freestanding | Medium (requires retrofitting) |

| Precision Lifting | High with articulating models | Moderate |

| Installation Complexity | Moderate | High (structure-dependent) |

Dive into the full comparison in Cranes and jib cranes solutions.

When selecting a smart jib crane, consider:

Available installation space

Desired automation level

Required lifting capacity and frequency

Budget for sensors, controllers, and integrations

Workforce readiness for digital control systems

Smart functionality is a long-term investment—reducing downtime, improving safety, and enhancing performance over time.

To begin planning, revisit your application needs and match them with the right smart features. Start by learning how to install your preferred model here: how to install jib cranes.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.