In industrial environments where precision, safety, and load management are paramount, understanding how to calculate jib crane load capacity is vital.

This guide breaks down the essential factors, formulas, and practical considerations needed to accurately determine the load-bearing capability of various jib cranes—including articulating and pillar-mounted versions—while also integrating automation and smart system planning for future scalability.

If you're unfamiliar with the basics, we recommend starting with What is a jib crane?.

Load capacity refers to the maximum weight a jib crane can safely lift under defined operating conditions. Exceeding this limit risks structural failure, equipment damage, and workplace injuries. For these reasons, accurate calculation is critical during both installation and ongoing operation.

Misjudging load capacity can lead to:

Crane column deformation

Boom deflection or failure

Hoist or trolley malfunction

OSHA safety violations

Learn more about smart planning and innovations in Industrial jib cranes in the future.

Before diving into formulas, it’s important to understand the elements that influence load capacity:

Jib Arm (Boom): Horizontal beam where the load is supported

Mast or Pillar: Vertical column that supports the boom

Mounting Base: Floor, wall, or ceiling attachment point

Hoist & Trolley: Components that bear and move the load

Rotation Range: Impacts the dynamic forces applied on the structure

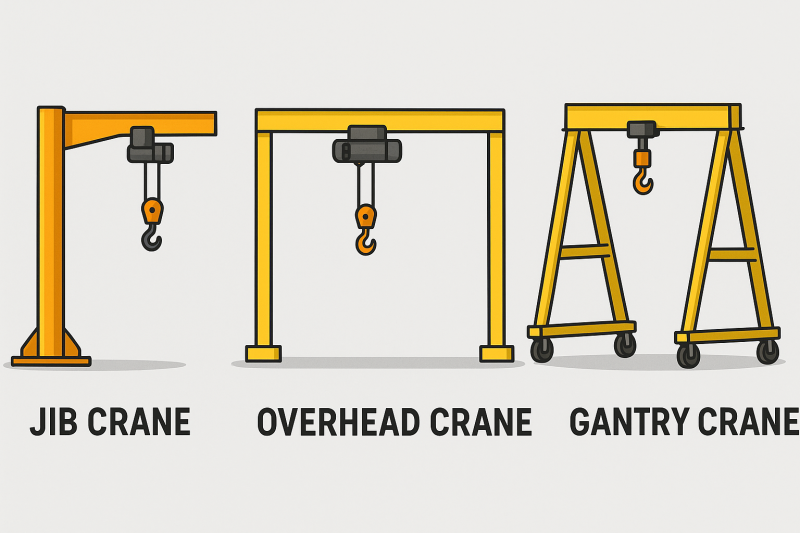

Each jib crane type—freestanding, wall-mounted, ceiling-mounted, or articulating—has different structural demands and calculation methodologies.

For a comparison with other crane systems, visit Jib cranes vs overhead cranes systems.

The calculation typically depends on moment load, stress tolerance, and deflection criteria. Here's a basic engineering formula used for freestanding jib cranes:

M = W × L

Where:

M = Moment at the base of the jib crane (in Newton-meters or pound-feet)

W = Load (weight in kg or lbs)

L = Distance from pivot point to load (arm length in meters or feet)

This moment value must not exceed the allowable moment of the base and structural components.

Material yield strength (e.g., steel grade)

Mounting surface strength and anchoring

Boom deflection limits (commonly ≤ 1/150 of arm length)

Full 360° rotation

High load capacity

Anchored to reinforced concrete foundations

Assume a 3-meter arm length and allowable moment of 15,000 Nm:

Max Load = 15,000 ÷ 3 = 5,000 N (~510 kg or 1124 lbs)

Mounted on existing building columns

Typical rotation: 180°–200°

Load capacity depends heavily on wall strength

Important to use structural analysis tools to assess wall load-bearing capacity and anchor bolt design.

Explore actual setup guidance in What is a crane application.

Suspended from ceiling beams

Ideal for cleanrooms and space-constrained areas

Ensure beam deflection under load does not exceed acceptable thresholds. Always check structural load charts of building steelwork.

In real-world applications, static weight isn’t the only concern. Engineers must also consider:

Dynamic loads from acceleration or swinging

Impact forces during lifting or lowering

Wind loads (especially for outdoor or semi-exposed cranes)

A common engineering adjustment is applying a safety factor between 1.25 to 1.5 to the total calculated load to compensate for these forces.

Maximum allowable deflection is critical to avoid excessive sagging or bending:

Max Deflection ≤ L / 150

Where:

L = Length of the jib arm

For example, a 3-meter arm should not deflect more than 20 mm under maximum load.

Learn more about how load and structure interact at How a Jib Crane works?.

Modern automated jib cranes feature real-time load monitoring, predictive maintenance alerts, and torque limiters.

Prevents overloads

Assists with balanced load distribution

Reduces manual monitoring and error

Automated control systems are especially useful for articulating jib cranes that must navigate complex paths with high precision.

For operation insight, explore How to operate a jib crane.

All jib crane load capacity calculations must align with safety standards such as:

OSHA 1910.179

ANSI B30.11 & B30.17

ASME BTH-1 Design of Below-the-Hook Lifting Devices

Always consult a qualified structural engineer for critical load-bearing calculations and local regulation compliance.

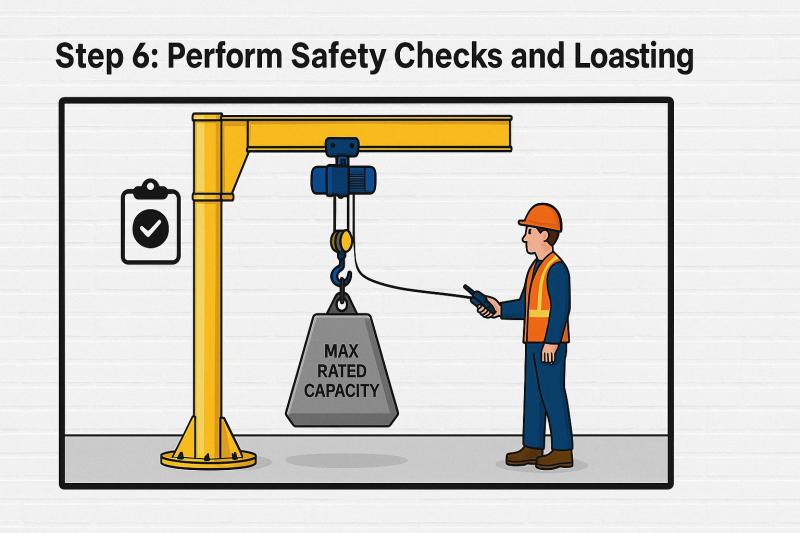

Never exceed rated capacity, even temporarily

Use load indicators and limit switches

Inspect for signs of stress, deformation, or fatigue

Maintain accurate documentation of all crane ratings and calibrations

Accurately calculating load capacity is essential to unlocking the full potential of your jib cranes. From the structure’s base moment to boom deflection and load positioning, every variable plays a role in ensuring safety and performance.

Whether you're working with a freestanding, wall-mounted, or articulating jib crane, these calculations help you lift with confidence.

For a foundational understanding, revisit What is a jib crane? and begin applying these principles across your projects.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.