Highly versatile, these cranes provide efficient lifting solutions across various industries. Portable gantry cranes, specifically, offer unparalleled flexibility, mobility, and convenience—ideal for construction sites, workshops, manufacturing plants, warehouses, and shipyards.

In this comprehensive guide, we'll detail how you can build your own gantry crane, specifically focusing on how Aardwolf's renowned portable crane models, like the Aardwolf AGC-1000, can inspire and enhance your design.

A gantry crane consists of a horizontal beam (girder) supported by vertical legs. The legs are typically mounted on wheels or casters, allowing the crane to move freely within a workspace. Unlike overhead bridge cranes fixed permanently to structures, gantry cranes provide flexibility, versatility, and portability, perfect for dynamic environments.

Portable gantry cranes, such as the Aardwolf AGC-1000, offer significant advantages. Built from lightweight yet robust aluminum, the AGC-1000 combines ease of transportation, corrosion resistance, and substantial lifting capabilities.

Key features of the Aardwolf AGC-1000:

Load Capacity: Supports up to 1,000 kg (2,204 lbs).

Adjustable Height: Height adjusts up to 3.1 meters.

Span Width: Maximum span of 3.1 meters.

Portability: Quick assembly/disassembly makes relocation easy.

Material Quality: Constructed of corrosion-resistant aluminum.

This model is perfect for job sites requiring frequent relocation, setup, and teardown without sacrificing structural integrity.

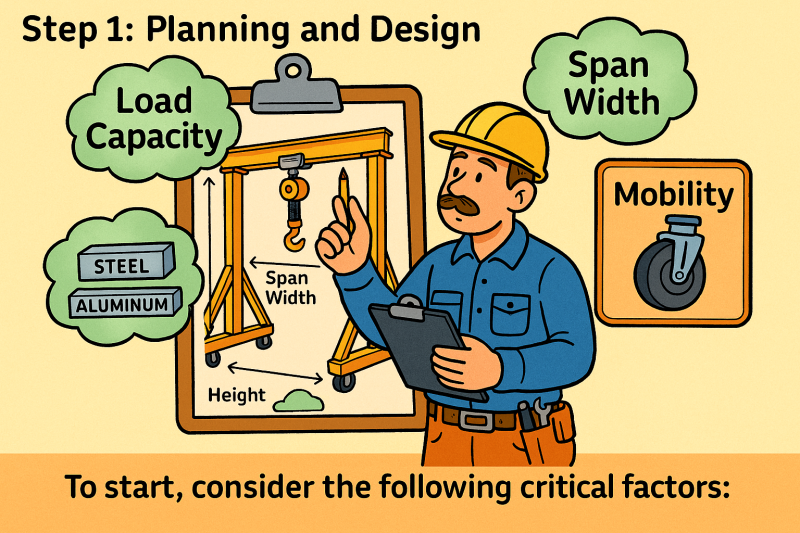

To start, consider the following critical factors:

Load Capacity: Determine the maximum load your crane will need to lift. Overestimate slightly to provide a margin for safety.

Span Width: Measure the workspace to define how long your crane beam must be.

Height Requirements: Identify the tallest object you'll need to lift or maneuver under.

Materials: Steel or aluminum are common choices. Steel provides strength for heavier loads, while aluminum—used in Aardwolf products—is ideal for lightweight portability.

Mobility: Decide between fixed placement or mobile capability. Include high-quality casters, similar to those used by Aardwolf, for maximum maneuverability.

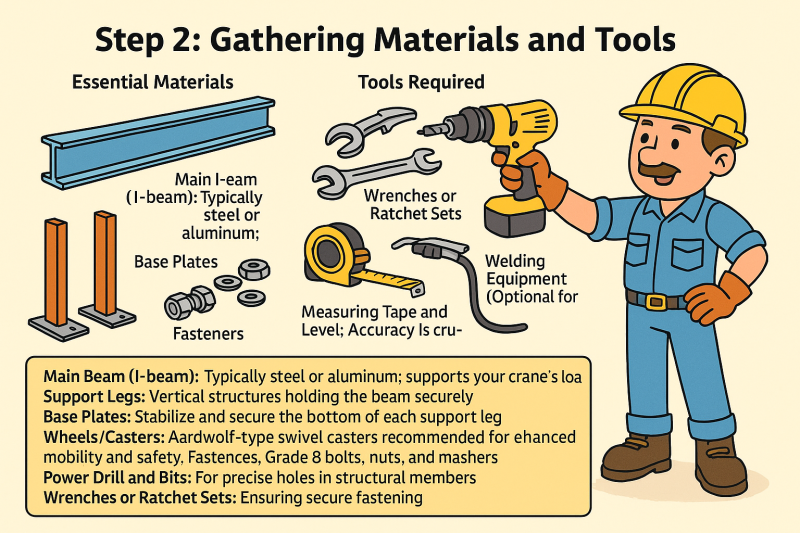

Main Beam (I-beam): Typically steel or aluminum; supports your crane’s load.

Support Legs: Vertical structures holding the beam securely.

Base Plates: Stabilize and secure the bottom of each support leg.

Wheels/Casters: Aardwolf-type swivel casters recommended for enhanced mobility and safety.

Fasteners: Grade 8 bolts, nuts, and washers.

Power Drill and Bits: For precise holes in structural members.

Wrenches or Ratchet Sets: Ensuring secure fastening.

Measuring Tape and Level: Accuracy is crucial.

Welding Equipment: Optional for more permanent structural connections.

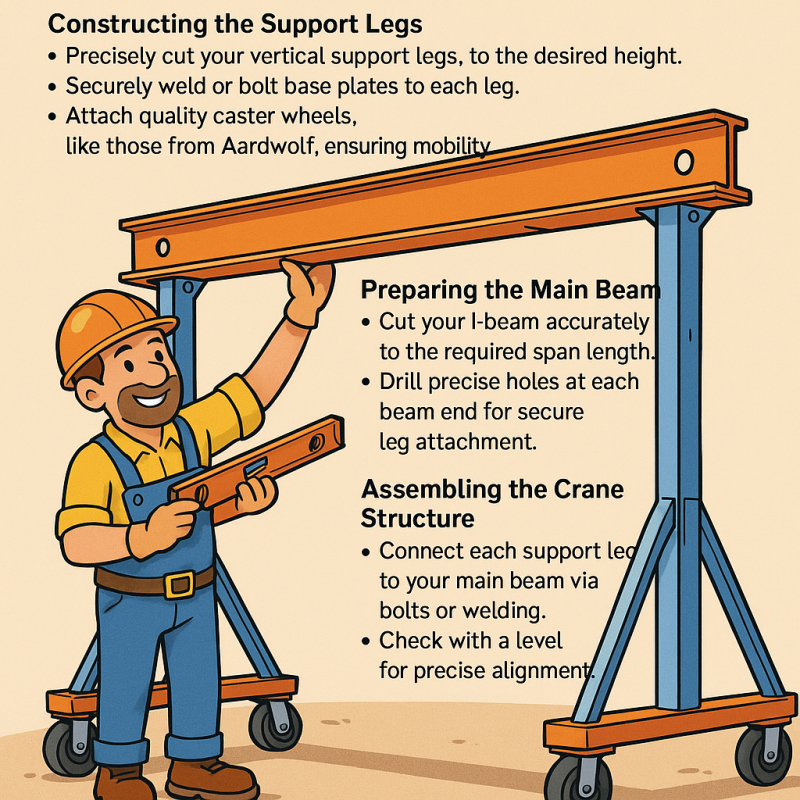

Precisely cut your vertical support legs to the desired height.

Securely weld or bolt base plates to each leg.

Attach quality caster wheels, like those from Aardwolf, ensuring mobility.

Cut your I-beam accurately to the required span length.

Drill precise holes at each beam end for secure leg attachment.

Connect each support leg to your main beam via bolts or welding.

Check with a level for precise alignment.

Incorporate additional cross-bracing for enhanced stability, inspired by Aardwolf’s robust designs.

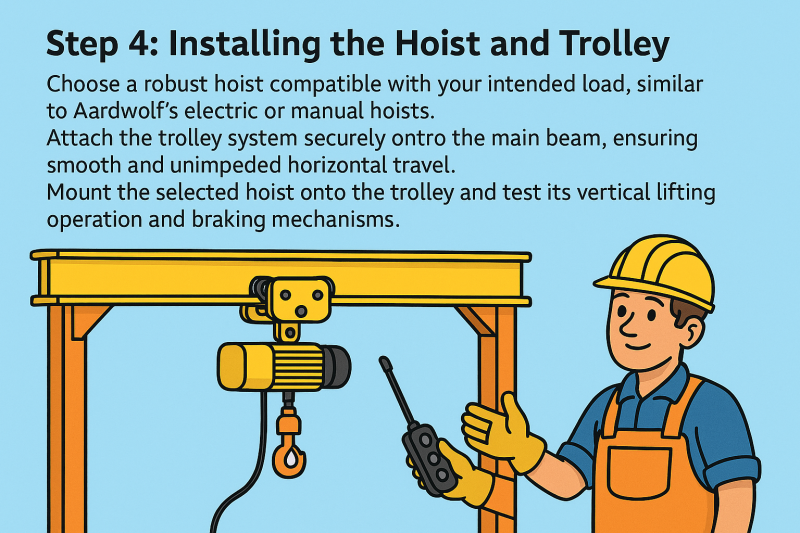

Choose a robust hoist compatible with your intended load, similar to Aardwolf’s electric or manual hoists.

Attach the trolley system securely onto the main beam, ensuring smooth and unimpeded horizontal travel.

Mount the selected hoist onto the trolley and test its vertical lifting operation and braking mechanisms.

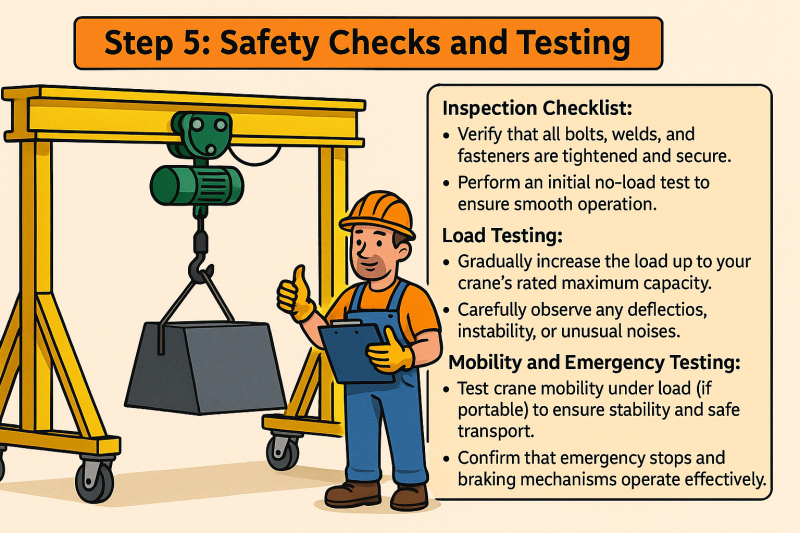

Verify that all bolts, welds, and fasteners are tightened and secure.

Perform an initial no-load test to ensure smooth operations.

Gradually increase the load up to your crane’s rated maximum capacity.

Carefully observe any deflection, instability, or unusual noises.

Test crane mobility under load (if portable) to ensure stability and safe transport.

Confirm that emergency stops and braking mechanisms operate effectively.

The Aardwolf AGC-1000 illustrates a best-practice portable gantry crane design. With a robust aluminum build, adjustable height, easy portability, and a significant load-bearing capacity, it provides unmatched operational versatility.

Common Use Cases Include:

Construction Sites: Lifting steel beams, pipes, prefabricated components, and HVAC systems.

Workshops: Positioning heavy machinery parts precisely.

Warehousing: Efficiently moving and stacking bulky items like engines, pallets, or large equipment.

Shipyards: Handling heavy marine components during repair or assembly operations.

Construction: Rapid deployment at job sites to safely handle structural steel or concrete panels.

Manufacturing: Assembling large machinery or equipment precisely and safely.

Warehouses: Transporting heavy goods, enhancing operational efficiency.

HVAC Installations: Installing rooftop units or large ductwork systems safely.

Outdoor Events: Temporary setup for staging, lights, or audiovisual equipment.

To ensure your gantry crane remains safe and operational:

Routine Inspections: Check all structural components regularly for signs of wear or damage.

Regular Lubrication: Maintain smooth operation of wheels, bearings, and hoist mechanisms.

Proper Storage: Protect your crane from harsh environments when not in use, especially aluminum models like the AGC-1000.

Operator Training: Provide comprehensive safety training and operational guidelines for all crane users.

Aardwolf products set industry standards in quality, reliability, and safety. Their portable cranes like the AGC-1000 deliver:

Innovative Design: Practical features such as quick setup, adjustable heights, and effortless mobility.

Exceptional Durability: Corrosion-resistant aluminum, ideal for harsh conditions.

User-Friendly Operation: Minimal setup time, easy operation, and straightforward maintenance.

Safety Focused: Engineered with rigorous safety standards and features built-in.

Building a gantry crane demands careful planning, precise execution, and meticulous attention to safety protocols. By following the comprehensive guide provided above, and by examining high-quality models like the Aardwolf AGC-1000, you can effectively build a gantry crane suited to your exact needs. Leveraging robust materials, smart designs, and proven Aardwolf products will result in a reliable and efficient lifting solution.

Yes, with proper planning, tools, materials, and adherence to safety guidelines, you can build a functional and safe gantry crane.

Very portable. The AGC-1000 is specifically designed for easy assembly, disassembly, and transportation between job sites.

The Aardwolf AGC-1000 comfortably supports loads up to 1,000 kg (2,204 lbs).

By following this detailed guide, you'll have the knowledge to design, build, test, and maintain a gantry crane that will effectively meet your lifting needs for years to come, inspired by the precision engineering and thoughtful design principles exemplified by Aardwolf products.

References

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Aardwolf'un yeni ürünleri, özel teklifleri ve daha fazlası hakkında en son bilgileri almak için kaydolun.

Kaydolarak, Aardwolf'tan haberler, özel teklifler, promosyonlar ve diğer bilgileri içeren e-postalar almayı kabul etmiş olursunuz. İstediğiniz zaman aboneliğinizi iptal edebilirsiniz.