In industrial environments, these systems replace manual lifting with safe, efficient, and ergonomic automation.

At Aardwolf Industries, vacuum lifters are engineered not as general lifting tools, but as highly specialized, precision-built systems optimized for stone, glass, metal, and construction material handling. With an emphasis on rugged performance, advanced safety, and configurability, Aardwolf vacuum lifters redefine how companies approach heavy lifting tasks.

In Aardwolf’s definition, a vacuum lifter is a purpose-built lifting device that employs sealed vacuum suction pads to grip solid surfaces—such as marble, granite, concrete blocks, glass panes, or metal sheets—without damaging them. Each lifter features integrated control systems, vacuum generation modules, and safety monitoring mechanisms. They are designed to support vertical and horizontal lifting with minimal manual effort, eliminating traditional hoisting complications.

Unlike basic vacuum lifters, Aardwolf models offer modular pad configurations, onboard vacuum tanks, powered tilt functions, slide valve activation, and remote-control options. These features make them ideal for handling non-porous and semi-porous surfaces safely, reliably, and with maximum operator control.

Aardwolf vacuum lifters are built on robust components, each engineered for performance and operator safety.

High-Efficiency Vacuum Pump: The vacuum pump is the lifter’s primary driver. It evacuates air from the sealed space between the suction pads and the load, creating a negative pressure zone. Aardwolf offers electric, battery, and pneumatic pump configurations depending on the application and model.

Durable Suction Pads: Constructed from industrial-grade rubber or silicone, Aardwolf vacuum pads offer high elasticity and grip strength. They conform to the surface of the load to maximize contact area and maintain a secure hold, even on mildly uneven materials like rough granite. Standard sizes include 500 x 300 mm pads, but other options are available for specific tasks.

Slide Valve Control: The manual ON/OFF slide valve, found on many Aardwolf units, offers precise control over vacuum application and release. This allows for instant, secure attachment and smooth load detachment with minimal effort.

Integrated Vacuum Tank: Certain models, such as those in the AVLP series, are equipped with vacuum reservoir tanks. These tanks store backup suction to maintain grip in the event of power loss, adding a vital safety layer for critical lifting operations.

Ergonomic Handle Construction: Aardwolf lifters feature extruded aluminum handles that protect vacuum and air lines inside a strong, lightweight frame. Many systems allow adjustable handle extensions for better ergonomics, especially during repetitive or high-cycle tasks.

Visual and Audio Safety Systems: Operators benefit from real-time feedback through vacuum level indicators, alarms, and battery status displays. These systems alert the user when suction drops below a safe threshold or if the battery requires attention, ensuring safe operation at all times.

Tilting and Rotation Capability: Many Aardwolf lifters support 0–90° tilting and full 360° manual or remote rotation. These features allow flexible lifting orientations, which are essential when installing glass panels or maneuvering large slabs onto cutting tables or assembly lines.

AVLP Series – Vacuum Lifter Pro: Designed for stone and metal materials, the AVLP series includes models like AVLP1-250P, AVLP2-500P, and AVLP4-P-1000. These units operate on 12V rechargeable battery systems and include vacuum tanks, ergonomic handles, alarms, and tilting options. They support weights ranging from 125 kg to 1000 kg and feature pneumatic tilting for effortless vertical-to-horizontal positioning.

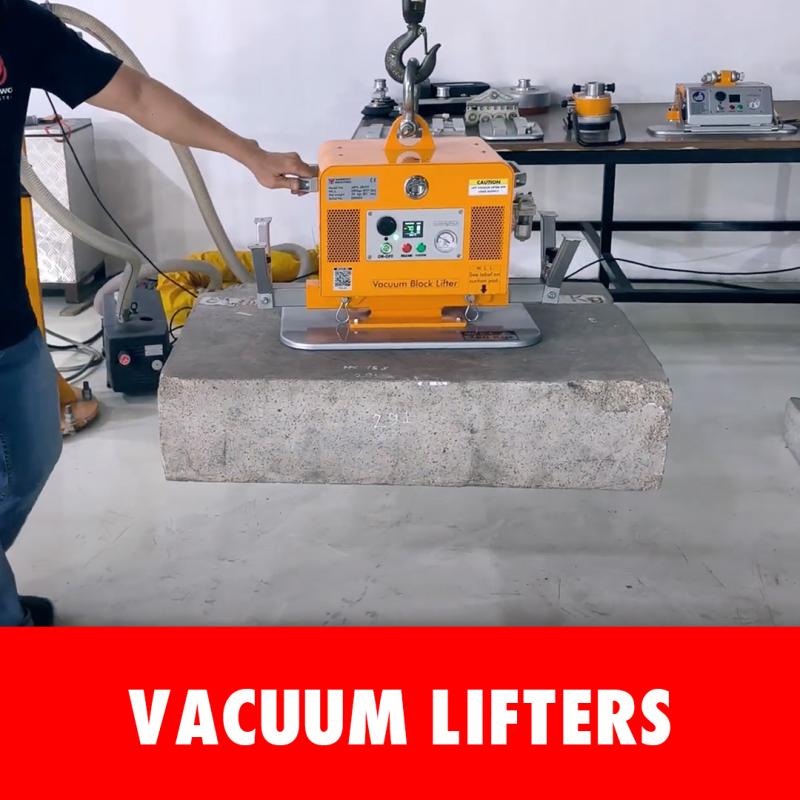

AVBL Series – Vacuum Block Lifters: Engineered specifically for block-shaped loads such as concrete, construction stone, or precast panels, the AVBL series includes AVBL-380 and AVBL-1000. These models feature a fast pad-switching system, handle- or frame-mounted controls, and sound/visual alarms to maintain load security.

AMMVL Series – Mono Mechanical Vacuum Lifters: These self-powered lifters require no external electricity or air supply. AMMVL models are 100% duty cycle-rated for continuous operation and feature auto-locking mechanisms. The load cannot be released until the unit is lowered, making them ideal for round-the-clock industrial lifting.

FMVLA Series – Fork-Mounted Vacuum Lifters: Designed for integration with forklifts or mobile cranes, FMVLA vacuum lifters allow easy lifting of wide panels and sheets, including glass, metal, and laminated surfaces. Remote-controlled versions ensure safe operation from a distance.

ARGL and AVGLP Glass Lifters: Built with fragile surfaces in mind, these models feature multiple smaller vacuum pads for improved load distribution and damage prevention. Vertical and horizontal lifting modes are supported, with models like ARGL-500 and AVGLP8-800 catering to the glass manufacturing and installation industries.

AEVLP Series – Electric High-Capacity Lifters: With lifting capacities of up to 2000 kg, the AEVLP series features robust electric systems, large vacuum pads, and full-scale industrial usability. They are suited for handling steel sheets, structural glass, and prefabricated wall panels in demanding environments.

Built-In Safety Redundancy: Integrated alarms, vacuum tanks, and control sensors guard against sudden vacuum loss or system failure.

Versatile Mounting Options: From forklift attachment to crane integration, Aardwolf systems fit into existing lifting infrastructure.

Customizability: Pad configurations, lifting capacities, handle lengths, and materials can be customized to suit specific applications.

Minimal Maintenance: Designed with simplicity and reliability in mind, Aardwolf vacuum lifters require only periodic pad inspection, filter changes, and gasket replacement.

Mobility Solutions: Optional add-ons such as parking stations and portable cranes allow for mobile operation in large facilities.

Stone Handling: Ideal for moving heavy marble, granite, and engineered stone, Aardwolf vacuum lifters are commonly used in fabrication shops, construction sites, and monument assembly lines.

Glass Installation: With padded suction cups and tilting mechanisms, Aardwolf’s glass lifters help installers position large panes on buildings with millimeter precision.

Metal Sheet Fabrication: Vacuum lifters support precise feeding of large metal sheets into press brakes, cutting machines, and CNC tables without scratching or bending the material.

Concrete and Block Handling: AVBL and AVPL lifters enable safe transportation of concrete pavers, blocks, and preformed structural components, reducing manual labor and increasing lifting speed.

Logistics and Warehousing: From flat panels to sealed boxes, vacuum lifters improve efficiency and reduce injuries during repetitive lifting tasks in warehouses and packaging centers.

Aardwolf supports its vacuum lifters with worldwide parts availability, regional service teams, and on-demand customization. From North America and Europe to Asia and Australia, distributors and service centers ensure prompt assistance, product updates, and maintenance guidance.

Aardwolf vacuum lifters are not generic lifting aids—they are engineered systems developed to enhance material handling safety, precision, and efficiency across demanding industries. Whether you're installing glass façades, processing stone countertops, or moving precast panels on-site, Aardwolf offers the tools and technology to streamline your operations.

With a diverse product line, industry-leading safety features, and scalable configurations, Aardwolf vacuum lifters remain the trusted choice for professionals who demand performance without compromise.

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

11. Powered counterbalance Crane

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.