Among various lifting systems available, Jib Cranes stand out as versatile and reliable solutions suited for numerous industries. This detailed guide delves deeply into jib cranes, specifically discussing core specifications, key types—including the freestanding jib crane, wall mounted jib crane, ceiling mounted jib crane, articulating jib crane, and pillar jib crane—and their specific applications.

Explore precisely What is a smart Jib Crane and how modern features enhance crane operations and productivity in industrial facilities.

When selecting jib cranes for your operations, understanding their core specifications is essential. These factors directly affect the crane's performance, reliability, and overall efficiency:

The load capacity, or the maximum weight a crane can safely lift, is the most crucial specification. Load capacities typically range from light loads (250 kg) to heavy-duty capacities exceeding 10,000 kg, depending on crane type and structural integrity.

The span, or reach, refers to the horizontal distance from the pivot point (column or wall) to the furthest point of the jib arm. Typically ranging from a few meters to over 10 meters, the right span optimizes lifting coverage within your workspace.

The height under boom is the vertical clearance from the floor to the underside of the jib arm. Selecting an appropriate HUB ensures sufficient space for lifting and positioning items safely and efficiently.

Jib cranes vary significantly in rotational capabilities, ranging from limited arcs (180–200 degrees) to full 360-degree rotations. Choosing the right rotation capability depends on your workspace layout and operational requirements.

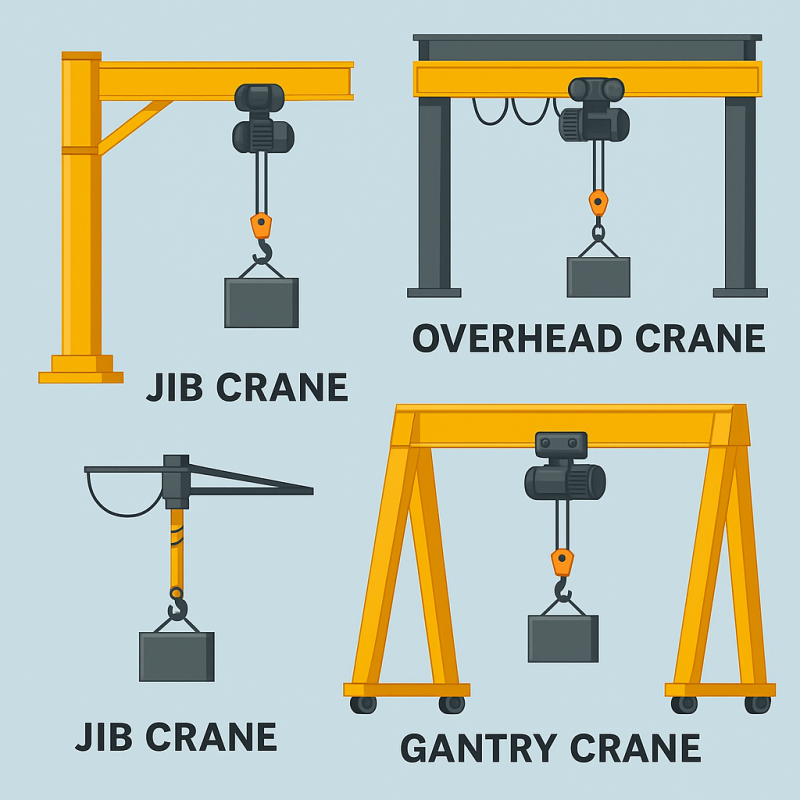

To maximize operational effectiveness, understanding various types of jib cranes and their specific applications is crucial. Here are common jib crane types with distinct characteristics and benefits:

The freestanding jib crane stands independently with robust anchoring into the floor, enabling full 360-degree rotation. It is ideal for open, unobstructed areas and heavy-duty lifting tasks.

Ideal Applications:

Manufacturing floors and assembly areas

Heavy machinery maintenance

Warehouses requiring high mobility

For more information, discover Types of Smart Jib Cranes and Ideal Applications.

A wall mounted jib crane attaches directly to existing walls or vertical structures, greatly optimizing space efficiency. These cranes offer rotation typically up to 200 degrees, making them ideal for narrow spaces and confined environments.

Ideal Applications:

Small workshops and service areas

Warehouses with limited floor space

Loading docks and production lines

A ceiling mounted jib crane utilizes overhead mounting to preserve valuable floor space. These cranes provide exceptional spatial efficiency and overhead mobility.

Ideal Applications:

Precision manufacturing facilities

Laboratories and cleanrooms

Spaces requiring unobstructed floors for machinery or production lines

The articulating jib crane features a multi-jointed arm allowing flexible, precise positioning around obstacles, making it extremely versatile and practical.

Ideal Applications:

Complex assembly lines

Machine shops and fabrication areas

Automotive repair centers where obstacle navigation is required

Gain deeper insights into Understanding the Role of Jib Cranes in Smart Facilities.

The pillar jib crane is mounted onto a solid pillar or column foundation, offering excellent stability and robust performance for stationary operations.

Ideal Applications:

Machining and metal fabrication areas

Permanent workstations requiring repetitive lifting

Heavy industrial environments

Modern industrial facilities increasingly rely on automation, IoT, and smart technologies. Incorporating these innovations transforms traditional jib cranes into intelligent, highly efficient tools.

Smart jib cranes integrate automation for precise, repeatable movements. Advanced control systems enhance operational accuracy, ensuring safe and reliable material handling.

Internet-of-Things (IoT) technologies allow real-time monitoring of crane operations, enabling proactive and predictive maintenance, reducing downtime, and significantly improving overall operational reliability.

Smart jib cranes come equipped with advanced safety features such as overload protection, automated limit switches, and emergency stops, significantly reducing risks of accidents and injuries.

Discover more insights on effective operations through our guide: How to operate a smart jib crane.

Understanding how jib cranes differ from other crane types, such as overhead cranes, is essential for selecting the right lifting solution:

Space Efficiency: Jib cranes utilize space more efficiently than overhead cranes, ideal for facilities with limited room.

Installation Cost and Complexity: Generally, jib cranes have lower installation costs and simpler setups compared to complex overhead crane systems.

Operational Flexibility: Jib cranes offer more precise, targeted lifting within a defined radius, whereas overhead cranes handle larger area coverage but with less precision.

For an in-depth comparison, explore our article on Comparing Jib Cranes and Overhead Cranes.

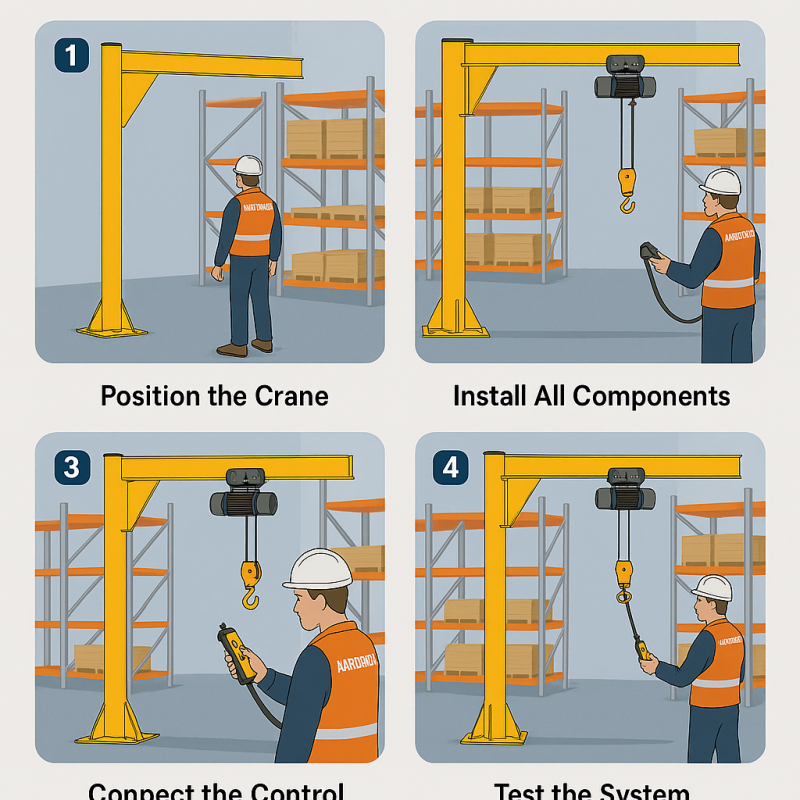

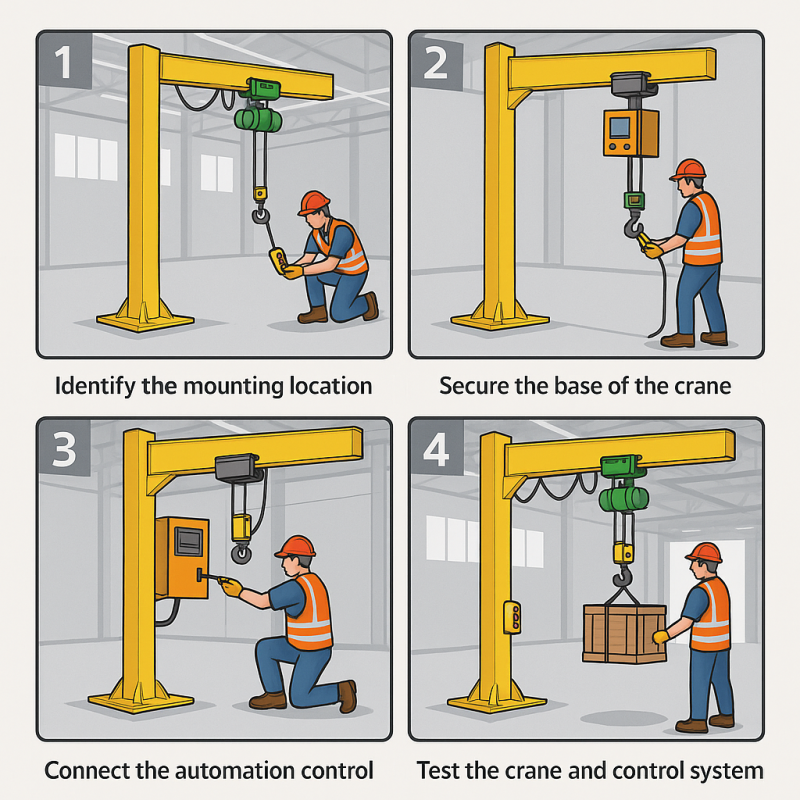

Successful implementation of jib cranes involves careful planning and execution:

Assessment: Evaluate operational requirements, available space, and load demands.

Selection: Choose a suitable jib crane type and configuration to meet operational demands.

Installation: Ensure proper installation, anchoring, and alignment according to manufacturer guidelines.

Integration: Incorporate automation and smart technologies for enhanced efficiency and safety.

Testing: Conduct comprehensive testing and certification before routine operations commence.

Detailed implementation guidelines are available in Steps to Smart Jib Crane Implementation.

Regular inspections of jib cranes are critical to ongoing safety, compliance, and performance. Scheduled assessments help detect issues early, reducing potential downtime and preventing accidents.

For practical guidelines, see our detailed Jib Crane Inspection Checklist to Ensure Safe Operations.

Understanding different jib crane types and their core specifications empowers facility managers and operators to choose solutions tailored precisely to their operational needs. Whether you require precision lifting in tight spaces or robust heavy-duty applications, jib cranes offer versatile, efficient, and smart solutions to meet varied industrial demands.

Ensure your facility remains competitive, safe, and efficient by making informed decisions about your lifting solutions. For further exploration and advice, begin by understanding What is a smart Jib Crane, helping to optimize productivity and enhance your operations effectively today.

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.