Operations that optimize the utilization of available space can significantly boost productivity and profitability. Among the various lifting solutions available, jib cranes stand out as the most efficient and adaptable choices, ideal for confined spaces and precise lifting operations. This guide explores different types of jib cranes—such as the freestanding jib crane, wall mounted jib crane, ceiling mounted jib crane, articulating jib crane, and pillar jib crane—detailing their applications and unique benefits, especially in space-constrained environments.

Learn exactly How to apply a smart Jib Crane to enhance your operational efficiency and maximize your workspace.

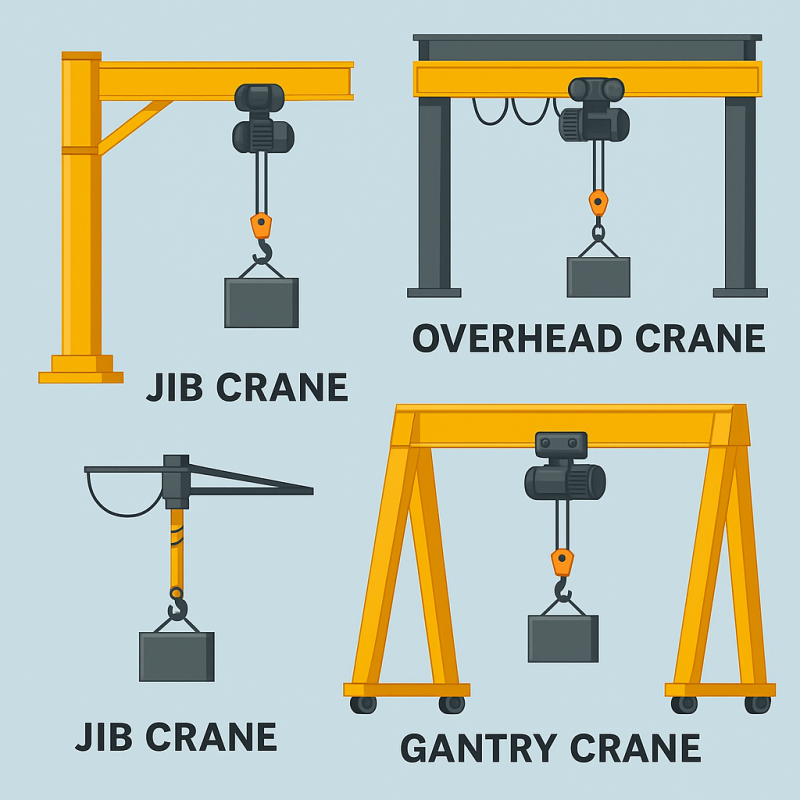

Jib cranes are designed specifically to handle materials in compact work areas where maneuverability and precision are paramount. Unlike bulky overhead cranes, jib cranes offer localized lifting solutions, seamlessly adapting to environments where every square meter counts.

The design of jib cranes inherently supports efficient space utilization. With a single arm, known as a jib, these cranes rotate around a central pivot point, dramatically reducing the operational footprint required for material handling.

Jib cranes excel at precision. The compact structure provides highly accurate lifting and positioning, ideal for precise assembly tasks, machining operations, and delicate material handling procedures.

Understand more about The key differences between a crane and a jib crane.

When considering a jib crane, selecting the appropriate type for your specific application is crucial. Here’s a detailed exploration of various jib cranes and their unique operational strengths:

Freestanding jib cranes are anchored securely to the floor, allowing a full 360-degree rotation, providing maximum versatility for operations within an extensive area.

Advantages:

Complete rotation around the anchor point.

Independent support structure suitable for heavy lifting.

Ideal for open-floor environments or assembly areas.

A wall-mounted jib crane is fixed directly onto walls or vertical structures, eliminating floor space usage entirely. These cranes provide around 180–200 degrees of movement, ideal for operations along a wall or in narrow aisles.

Advantages:

Significant space-saving potential.

Cost-effective installation using existing structures.

Excellent choice for workshops, small factories, or warehouses.

Gain in-depth insights from Wall Mounted Jib Cranes: Smart Tools in Tight Spaces.

A ceiling-mounted jib crane is mounted overhead, freeing up floor space entirely. It provides maximum area coverage without hindering floor-level activities.

Advantages:

Complete elimination of floor-space usage.

Optimal use in cleanrooms, laboratories, and precision manufacturing.

Increased accessibility around the workspace.

Articulating jib cranes feature flexible, multi-jointed arms that enable operators to maneuver around obstacles with precision. They provide superior flexibility compared to traditional jib cranes.

Advantages:

Exceptional maneuverability in confined spaces.

Ability to reach around corners or obstacles.

Ideal for complex assembly processes or cluttered environments.

Explore detailed specifications with jib crane specification.

Pillar jib cranes are permanently mounted to solid foundations, making them perfect for localized lifting activities where stability and repetitive tasks are common.

Advantages:

Highly stable and robust lifting capabilities.

Reliable performance for repetitive lifting operations.

Ideal for manufacturing stations and machining centers.

The integration of smart technologies significantly amplifies the value of jib cranes. Smart jib cranes incorporate automation, IoT (Internet of Things), and advanced control features, greatly enhancing operational efficiency, safety, and ease of use.

Automated load sensing and positioning.

Real-time monitoring and predictive maintenance alerts.

Enhanced workplace safety through automated safety controls.

Learn more about How to operate a smart jib crane to maximize your operational performance.

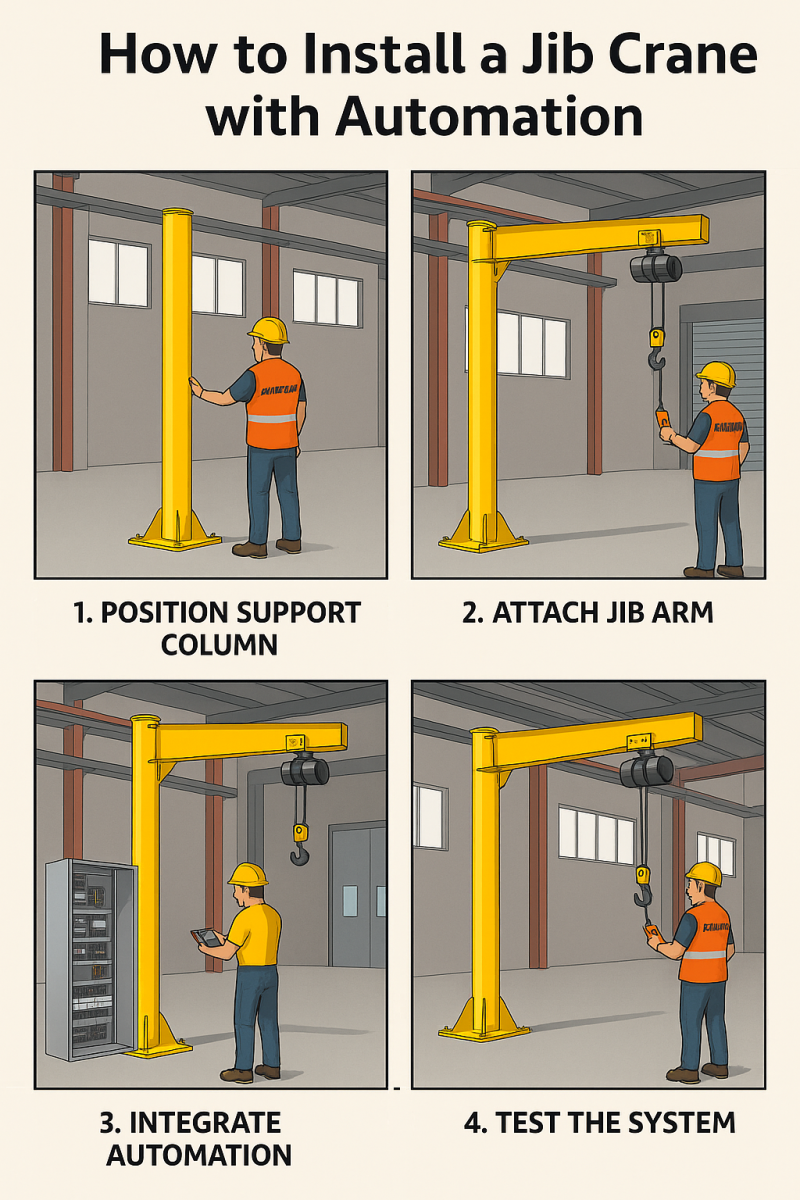

Proper installation is critical to ensure safety, reliability, and efficiency. Here is a concise summary of the essential steps involved:

Site Assessment: Analyze structural integrity and load-bearing capacity.

Foundation Preparation: Secure foundations or structures to handle crane loads.

Crane Assembly and Mounting: Carefully follow the manufacturer's assembly and installation guidelines.

Automation Integration: Connect and calibrate automation and control systems.

Testing and Calibration: Conduct rigorous operational and safety testing before deployment.

Follow the complete installation instructions with Jib Crane step-by-step guide.

Due to their compact design and operational flexibility, jib cranes are widely utilized in diverse industries including:

Manufacturing: Precision handling of components and machinery assembly.

Warehousing & Logistics: Efficient loading and unloading within restricted aisles.

Automotive Workshops: Safe and precise lifting of heavy automotive components.

Pharmaceutical & Laboratory Environments: High precision, minimal space utilization, and contamination control.

Understand clearly how crane application your facility can improve overall safety and operational efficiency.

Selecting the right jib crane involves careful evaluation of:

Operational Space: Assess the spatial limitations of your workspace.

Load Capacity: Define clear load requirements and frequency of operations.

Precision and Automation Needs: Determine the level of automated control required.

Making informed choices significantly enhances the value and longevity of your lifting equipment investment.

Investing in smart jib cranes prepares your facility for future technological advances and evolving industry standards. Their modularity, automation capabilities, and IoT integration ensure scalability and sustained operational performance.

Read more about future strategies and insights in our dedicated article on Wall Mounted Jib Cranes: Smart Tools in Tight Spaces.

Jib cranes present an ideal lifting solution tailored specifically for space-efficient operations. Whether you select a freestanding jib crane, wall-mounted jib crane, ceiling-mounted jib crane, articulating jib crane, or pillar jib crane, understanding their unique advantages ensures optimal utilization in your workspace.

Ready to maximize your operational efficiency and workspace? Discover more about How to apply a smart Jib Crane for your industrial needs today.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.