These versatile machines streamline daily operations, reduce manual strain, and increase throughput in manufacturing plants, warehouses, and workshops.

Whether it's a freestanding jib crane installed at a shipping dock or a wall mounted jib crane operating in a tight assembly bay, jib cranes are designed to optimize workflow. In this article, we explore how various types of jib cranes improve workplace efficiency, and how to choose the right one for your facility.

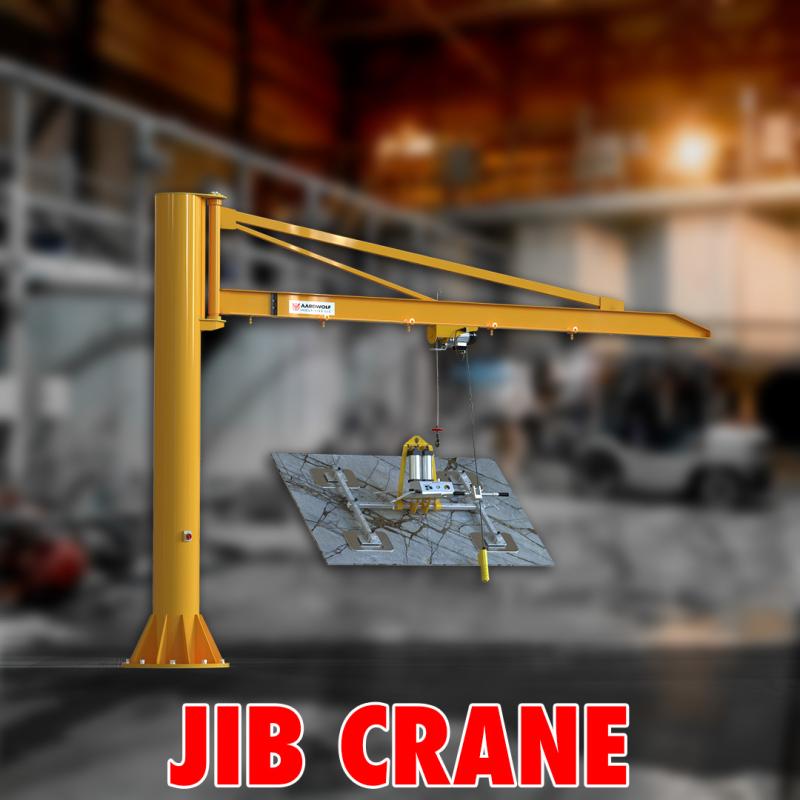

Jib cranes are lifting devices equipped with a horizontal arm—called a jib or boom—that supports a movable hoist. They allow radial movement of materials within a semi-circular or full-circle area, depending on their mounting type and configuration.

Jib cranes are commonly used for:

To understand the mechanical structure and operational logic, review Aardwolf Jib Cranes.

Different work environments call for different types of jib cranes. Here’s how each type contributes to performance, space management, and operator productivity.

A freestanding jib crane is installed on a reinforced concrete foundation and provides 360° rotation. It’s ideal for large floor spaces or outdoor operations that require independent lifting stations.

Efficiency Benefits:

Wall mounted jib cranes are affixed to vertical columns or walls and typically provide 180° to 200° swing coverage. These are excellent for production lines with limited floor space.

Efficiency Benefits:

Explore specific models like the Wall-mounted Jib Cranes Models.

A ceiling mounted jib crane is suspended from overhead steel structures and allows full rotation without interfering with floor traffic.

Efficiency Benefits:

An articulating jib crane has two rotating arms, offering greater flexibility and reach. This model is perfect for navigating around obstacles or machinery.

Efficiency Benefits:

Discover top-performing articulating cranes at How many types of Jib Cranes.

A pillar jib crane is bolted to the floor using a reinforced baseplate. While similar to freestanding models, it is often used for medium-duty applications and quicker installs.

Efficiency Benefits:

To see how types differ, visit How to compare Jib Cranes.

Jib cranes reduce time wasted in manual handling or repositioning by providing fast, targeted lifting. Operators can move loads with minimal physical effort, decreasing delays between tasks.

By handling heavy or awkward loads, jib cranes lower the risk of musculoskeletal injuries. They also reduce reliance on forklifts and improve visibility in narrow zones.

Wall-mounted and ceiling-mounted jib cranes eliminate the need for floor-based systems, which is particularly beneficial in production lines and confined facilities.

With ergonomic controls and smooth movement, jib cranes empower a single operator to lift and position materials that would otherwise require multiple people or complex rigs.

Jib cranes can be deployed in standalone stations or integrated into a larger material handling system. Facilities can expand or adapt workflows without major redesigns.

| Industry | Recommended Jib Crane | Why It Works |

|---|---|---|

| Warehousing | Freestanding or Ceiling | Large load handling and movement over wide areas |

| Automotive Assembly | Wall Mounted or Articulating | Compact footprint, precise part placement |

| Metal Fabrication | Pillar or Freestanding | Supports machine operators with medium-to-heavy parts |

| Food Processing | Ceiling Mounted | Keeps floors clean and contamination-free |

| Aerospace & Electronics | Articulating or Wall Mounted | Detailed, delicate assembly in tight spaces |

Installation impacts efficiency just as much as crane selection. Keep in mind:

For a step-by-step setup process, review How to boost efficiency with a Jib Crane.

As industries adopt smart manufacturing technologies, jib cranes are evolving with:

Stay informed on these advancements at Trends of Jib Cranes Installation.

From boosting productivity to improving safety and space management, jib cranes are an essential asset in any efficient workplace. Whether you choose a freestanding jib crane for heavy lifting or a wall mounted jib crane for streamlined assembly, the right crane will significantly enhance your operation.

If you're looking to scale your workflow, reduce physical strain, or simply make better use of your floor space, it’s time to integrate the right jib crane for your tasks.

Start by exploring Aardwolf Jib Cranes and selecting a model that fits your goals—because lifting smarter is working smarter.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.