Their adaptability, compact footprint, and ability to enhance workflow efficiency make them a staple in warehouses, manufacturing lines, workshops, and construction yards.

But with so many configurations—like freestanding jib cranes, wall mounted jib cranes, ceiling mounted jib cranes, articulating jib cranes, and pillar jib cranes—choosing the right one for your operation can feel overwhelming.

This article helps you make the best selection by breaking down each crane type, key decision factors, and real-world use cases, all while highlighting the critical role that jib cranes play in modern industrial settings.

The wrong crane can limit productivity, create safety risks, or cost more in installation and maintenance. The right jib crane does more than lift—it transforms your workflow by:

Reducing manual handling injuries

Improving load positioning accuracy

Increasing throughput in production

Saving floor space and reducing congestion

To stay informed on industry trends and crane evolution, check out Trends of Jib Cranes Models.

Before diving into decision-making factors, you should understand the core types of jib cranes available today. Each type serves a different purpose depending on load capacity, layout constraints, and workflow needs.

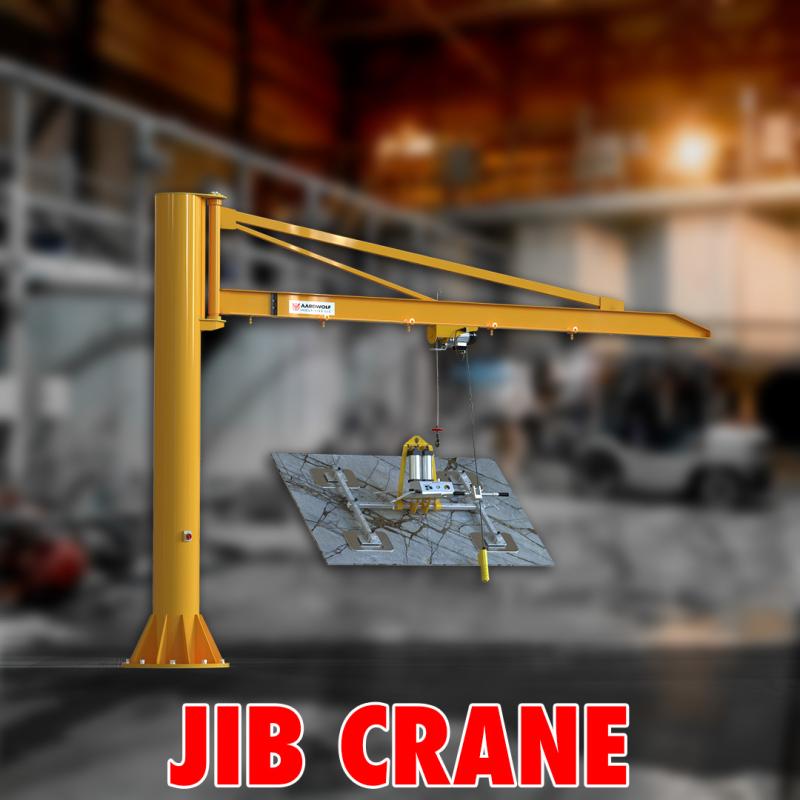

Freestanding jib cranes are mounted on a reinforced concrete foundation, offering 360° rotation and the highest lifting capacity among jib crane types.

Best for:

Heavy-duty lifting

Outdoor docks

Large, open warehouse zones

Benefits:

Full circular coverage

Independent of existing structures

High versatility in load movement

Wall mounted jib cranes attach to a vertical surface such as a wall or structural column, and typically offer up to 200° rotation.

Best for:

Assembly workstations

Production lines

Facilities with space constraints

Benefits:

Saves floor space

Economical to install

Perfect for repetitive lifting within work cells

Explore system configurations like A Wall-mounted Jib Crane system.

As the name implies, ceiling mounted jib cranes are suspended from building trusses or ceiling structures, enabling unobstructed floor movement.

Best for:

Cleanrooms

High-density production lines

Medical or electronic facilities

Benefits:

Keeps floor area open

Integrates seamlessly with modular layouts

Ideal for light- to medium-duty lifting

Articulating jib cranes feature two pivot points and offer unmatched flexibility when working around obstacles, corners, or tight areas.

Best for:

CNC machine servicing

Workstations with overhead obstructions

Confined fabrication spaces

Benefits:

Reaches into hard-to-access areas

Offers precise load placement

Increases operator safety and control

Learn more about models like AJC-AWM at How many kinds of Jib Crane.

Pillar jib cranes (also known as column-mounted cranes) are bolted to the floor using a steel baseplate and are suitable for medium-capacity tasks.

Best for:

Machine-side operations

Maintenance facilities

Light to moderate repetitive lifting

Benefits:

Easier to install than freestanding cranes

Ideal for small-area deployments

Adaptable for mid-range loads

Discover more about foundational setups in The core installation of Jib Cranes.

Now that you’re familiar with the main types, here’s how to evaluate which jib crane is right for your application.

How much weight will you lift regularly? Overloading a jib crane reduces lifespan and creates safety risks. Choose a model with 20%–30% headroom above your average load.

Different crane types offer varying rotation angles:

360° – Freestanding, ceiling-mounted

180° to 200° – Wall-mounted

Variable – Articulating (can adjust arm angles for tight spots)

Your facility’s layout and structure will often dictate crane type:

Concrete slab → Freestanding or Pillar Jib

Structural wall → Wall-mounted

Ceiling truss → Ceiling-mounted

Calculate the maximum and minimum reach needed from the crane’s centerline. Articulating cranes are best for uneven or multi-station coverage.

Heavy-duty operations with continuous use require robust cranes with motorized trolleys or rotation. Occasional use may justify a more basic manual model.

| Industry | Recommended Crane Type | Why It Fits |

|---|---|---|

| Steel Fabrication | Freestanding or Pillar | Handles heavy loads in open bays |

| Automotive Assembly | Wall Mounted or Articulating | Reaches tight work cells with repetitive motion |

| Aerospace Production | Ceiling Mounted or Articulating | Precision positioning and overhead efficiency |

| Warehousing & Logistics | Freestanding or Wall Mounted | High-speed load transfer across dock and storage zones |

| Small Machine Shops | Pillar or Articulating | Compact, ergonomic lifts for close-range operations |

For application-specific insights, review Main Cases for Different Jib Cranes.

While upfront cost is always a consideration, the total operational efficiency of a jib crane often outweighs initial pricing. Ask:

How much time will be saved in load handling?

How many labor hours can be reduced?

What is the ROI in safety improvements?

Can this crane scale with future production needs?

Modern jib crane systems continue to evolve with trends like:

IoT-enabled controls for load monitoring

Automated swing limits and collision detection

Hybrid crane-vacuum systems for non-porous lifting

Modular boom extensions for longer reach

Stay on top of developments with Trends of Jib Cranes Models.

Choosing the right jib crane for your operation means balancing load requirements, space constraints, structural conditions, and frequency of use. With a wide variety of models—ranging from freestanding and pillar jib cranes to articulating and wall-mounted systems—you’re sure to find a solution that fits.

Investing in the proper crane setup can:

Reduce material handling bottlenecks

Improve worker safety and comfort

Boost overall production throughput

Explore your options with Aardwolf’s lineup, starting with The core installation of Jib Cranes or review real-world success with A Wall-mounted Jib Crane system.

References

1. How to operate a Jib Cranes safely

2. Over brace jib crane wall mounted

4. Is a Jib Crane a Gantry Crane

5. Articulated Jib Crane Wall Mounted

7. Manual Counterbalance Crane

9. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.