Aardwolf, a world-renowned manufacturer in material handling equipment, offers an exceptional line of glass vacuum lifters tailored for these tasks.

Glass vacuum lifters operate by using suction pads powered by vacuum pumps to hold and lift glass without physical strain or damage. This article explores how a glass vacuum lifter works, emphasizing the innovative technology and design of Aardwolf’s leading models.

What Is a Glass Vacuum Lifter?

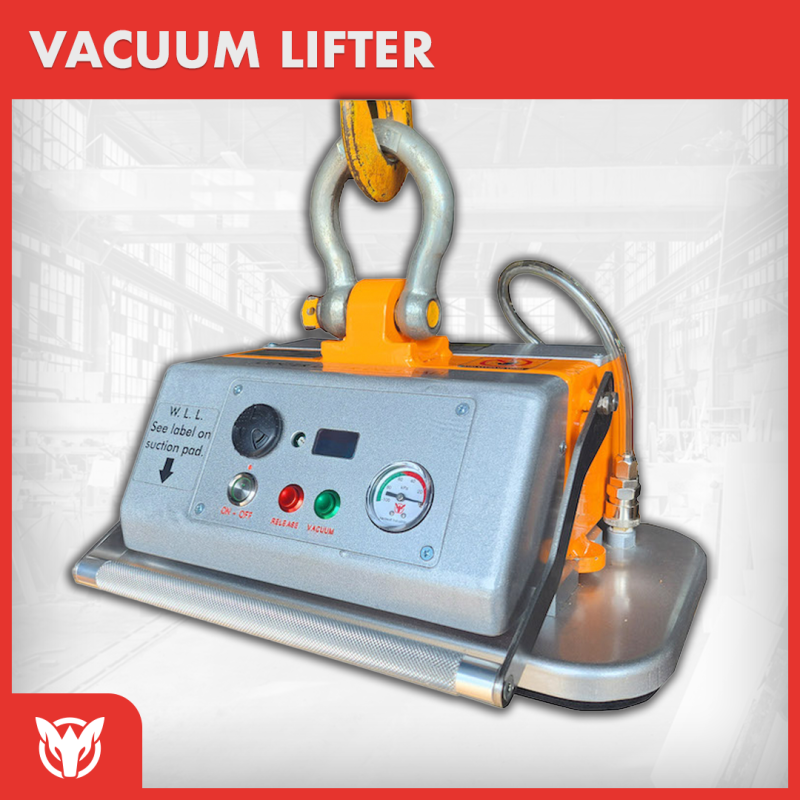

A glass vacuum lifter is a device that uses negative air pressure (vacuum suction) to securely grip and lift glass sheets. This lifting system is especially valuable for handling large, flat, and fragile materials like windows, curtain walls, and glass panels.

Aardwolf’s vacuum lifters are designed to handle a range of weights and dimensions, with some models capable of lifting up to 2000 kg. These machines significantly reduce manual handling, improve workplace safety, and boost productivity.

How Does a Glass Vacuum Lifter Work?

Glass vacuum lifters from Aardwolf work on the principle of vacuum suction and controlled lifting. The typical operation includes:

Vacuum Pump

A motor-driven or pneumatic vacuum pump generates suction by removing air from the suction pads. In Aardwolf’s lifters like the AEVGLP4-500, this is managed by an electric pump with automatic pressure control.

Suction Pads

These are rubber or polyurethane pads that form an airtight seal against the glass surface. Aardwolf offers various pad configurations — from 2 to 10 pads — depending on the load requirement and panel size.

Control System

Operators can control the lifter via ergonomic handles or remote control systems. Safety alarms, vacuum gauges, and slide valves allow precise attachment and release. Models such as the AVBL1000 include visual and audio warning

Lifting and Tilting Mechanism

Aardwolf glass lifters can tilt from 0° to 90° and rotate up to 180°, either manually or using electric actuators. This allows for vertical and horizontal installation of glass sheets in building façades or factories.

Load Release

When the vacuum is deactivated, air returns to the suction cups, breaking the seal and releasing the load gently and safely.

Popular Aardwolf Glass Vacuum Lifters

Aardwolf offers a broad selection of vacuum lifters, each optimized for specific weight ranges, environments, and handling needs.

Battery-Powered Models

ARGL-500: Lifts up to 500 kg. Designed for installation of large windows and sheets. Operates with onboard DC battery and features movable pads for flexible sizing.

AVBL1000: Heavy-duty model for handling up to 1000 kg. Comes with a robust aluminum frame, vacuum tank, and battery-powered vacuum system.

Electric Glass Vacuum Lifters

AEVLP8-1000: Can handle 1000 kg using eight large pads (300 mm+). Designed for handling large sheets of metal or glass, commonly used on construction sites2022_Vacuum Lifter.

AEVLP4-500: Four-pad configuration, ideal for mid-size panels up to 500 kg. Features pressure switch control and automatic vacuum pump activation.

Pneumatic Glass Lifters

AVGLP6-500: Operates via compressed air, ideal for lifting and rotating glass up to 500 kg. Allows for angular movement, offering flexibility during installations.

AVGLP2-AR: Smaller capacity (200 kg) but ideal for tight spaces or internal use.

Handy and Compact Options

AHVL500: Lightweight and operated via a venturi vacuum generator. No electricity needed, perfect for small shop floors or mobile setups.

SPVL-100: Designed for manual lifting, handling up to 120 kg in vertical or horizontal orientation.

Advanced Features in Aardwolf Lifters

Aardwolf lifters, particularly slab lifters, incorporate several advanced features to enhance safety, efficiency, and ease of use. These include automatic locking mechanisms, precision rollers, and durable construction with surface protection. Specific models like the AL30AR and AL20AWJR offer these features, along with extra-wide jaws and compact designs

Dual Vacuum Circuits: Built-in redundancy systems in models like the ARGL-500DS ensure operation continues safely even in case of system failure.

Visual/Audio Alarms: Alerts operators in real time if vacuum pressure drops.

Vacuum Tanks: Provide extra security by maintaining suction temporarily even during power loss.

Remote Operation: Several models support remote control for safer distance operation, especially during high-risk lifts.

Benefits of Using Aardwolf Glass Vacuum Lifters

Aardwolf glass vacuum lifters offer several benefits, including enhanced safety, increased efficiency, and reduced risk of damage to materials. They are designed to handle glass and other materials with precision and reliability, minimizing manual effort and maximizing productivity.

Enhanced Workplace Safety

Operators can lift heavy glass sheets without physical exertion. Built-in alarms and vacuum indicators prevent accidents during lifting operations.

Improved Productivity

Quick suction and release cycles reduce downtime between lifts. Aardwolf’s models with adjustable arms and pad configurations improve workflow speed.

Precision Handling

The ability to tilt and rotate glass sheets on command helps with accurate installations in tight or elevated spaces.

Versatility

Aardwolf glass vacuum lifters handle a wide variety of materials beyond just glass, including polished stone, metal sheets, and laminated panels.

Applications Across Industries

Aardwolf’s glass vacuum lifters are used in numerous sectors:

Glazing and Window Installation: Perfect for setting large panes in high-rise buildings.

Curtain Wall Fabrication: Lifts and positions heavy architectural panels with ease.

Glass Manufacturing: Transports sheets from cutting stations to packaging or storage.

Interior Fit-Out: Used in mirror installation, interior glass wall systems, and large decorative panels.

Automotive and Aerospace: For handling glass windshields or transparent structural components.

Why Aardwolf Is the Preferred Brand

Engineering Excellence

Aardwolf has a legacy of innovation in the material handling sector, serving the glass, stone, and metal industries with products known for performance and durability.

Worldwide Availability

Aardwolf products are available in the USA, Australia, Germany, Vietnam, India, and beyond, with global support centers for service and spare parts.

Customization and Flexibility

Clients can request tailored designs to fit unique project requirements — whether it’s custom pad layouts, mounting systems, or power types.

The Aardwolf AAdvantage

Backed by engineering expertise and dedicated support, Aardwolf ensures that every lifter not only performs flawlessly but also complies with the latest safety and efficiency standards.

Conclusion

Understanding how a glass vacuum lifter works is crucial for streamlining material handling operations and ensuring the highest level of safety in any industrial or construction environment. With increasing demands for precision, speed, and ergonomics in glass installation and fabrication, Aardwolf’s technologically advanced vacuum lifters provide the perfect solution.

From compact battery-powered models for workshop use to heavy-duty electric or pneumatic lifters for construction sites, Aardwolf offers equipment to handle glass sheets of every size and shape. Their vacuum lifters are engineered to lift up to 2000 kg, making them ideal for installing glass curtain walls in high-rise buildings, maneuvering laminated or insulated glass panels, and transporting fragile materials within factories or warehouses.

Aardwolf glass vacuum lifters are equipped with features such as:

Adjustable vacuum pad configurations for different panel dimensions.

360-degree rotation and 90-degree tilt for precise placement.

Remote control systems and visual/audio safety alarms to keep operators informed and secure.

Integrated vacuum tanks to maintain grip even during power interruptions.

Dual vacuum circuits in select models for redundancy and enhanced safety compliance.

Applications extend across multiple industries:

Construction and architecture – Installing building façades, skylights, and large window panels.

Glass manufacturing and processing – Moving glass between production lines or machines.

Automotive and aerospace – Lifting windshields and specialty glass components.

Interior design and furniture – Installing mirrors, shower enclosures, or glass dividers.

What sets Aardwolf apart is not just the engineering of each lifter, but the full ecosystem of support including jib cranes, parking stations, and custom lifting solutions—all designed to integrate seamlessly with your workflow. Their equipment is built for durability, with rugged aluminum and steel construction that withstands daily use in demanding environments.

In short, whether you are lifting 100 kg workshop glass panels or installing massive 2-ton insulated glass units on-site, Aardwolf’s range ensures that you have the right tool for the job. Their dedication to innovation, safety, and customer-specific solutions makes Aardwolf the trusted name in vacuum lifting technology.

If you’re looking to optimize your handling process, reduce labor risks, and increase operational efficiency, understanding how a glass vacuum lifter works—and choosing the right Aardwolf system—will give your business a distinct competitive edge.

To explore more about Aardwolf’s lifting equipment, visit www.aardwolf.com.au or contact their global support centers for a tailored consultation.

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.