What used to be simple mechanical lifting devices have now become intelligent, automated systems that improve throughput, reduce labor strain, and integrate seamlessly into Industry 4.0 environments.

Whether you operate a busy distribution warehouse or a precise assembly line, embracing automation in your jib crane system can dramatically enhance productivity and long-term ROI. Let’s explore how, why, and when automation becomes an essential upgrade for your crane setup.

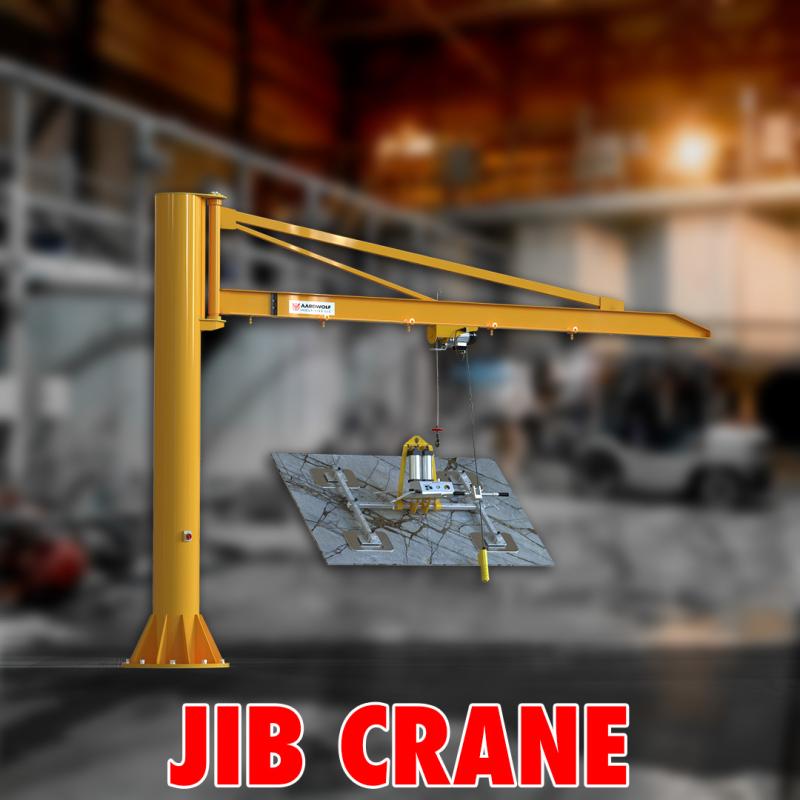

Jib cranes are known for their versatility and compact design, making them ideal for localized lifting applications. These cranes consist of a horizontal boom (or jib) that supports a hoist and trolley. The boom is anchored to a column, wall, or ceiling, allowing loads to move within a fixed radius.

In many production setups, Jib cranes play an important role in your warehouse—helping to handle loads quickly, accurately, and safely in compact workspaces where larger overhead cranes may not fit.

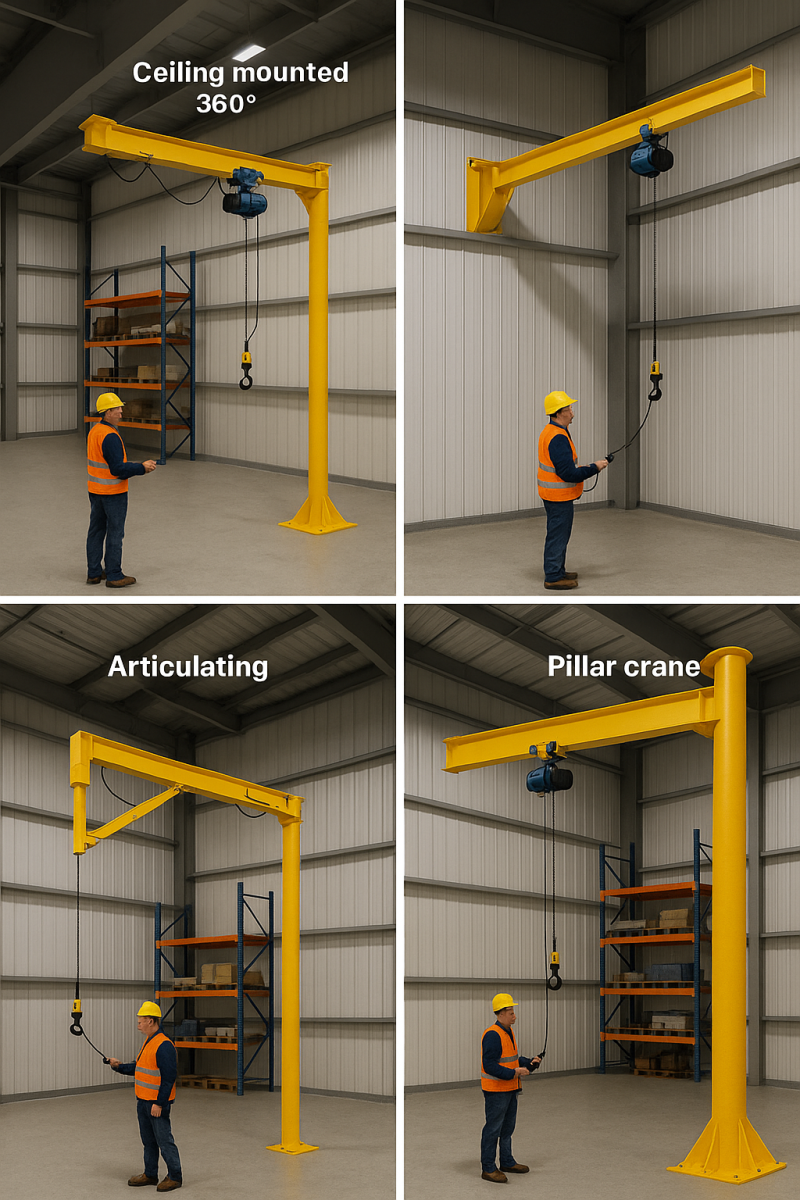

Understanding the differences in crane types helps you choose the right automation path. According to the industry breakdown on how jib cranes work in many industries, these are the most common types that can be automated:

Mounted on a reinforced concrete base

Provides full 360° rotation

Ideal for large open-floor spaces

Easily supports motorized slewing and programmable hoist movement

Attached to a building’s structural wall

180°–200° swing arc

Great for tight production lines

Can be upgraded with smart hoists, soft-start motors, and load sensors

Suspended from roof beams or trusses

Maximizes floor space

Common in assembly or food processing environments

Suited for integration with conveyor systems and PLC controls

Equipped with dual-arm movement

Offers enhanced flexibility in small or obstructed areas

Ideal for tasks near machines or corners

Supports advanced automation like zone tracking or push-button retraction

Smaller units typically fixed to a workbench or post

Best for repetitive, light-duty lifting

May include manual or semi-automatic hoists

Automation potential increases with the complexity of the operation. Review the mechanical distinctions in Jib cranes vs overhead cranes.

Automation in jib cranes isn’t about robots replacing workers—it’s about enabling better control, accuracy, and safety. Here’s what modern automation includes:

Smart systems allow for precision-controlled slewing, lifting, and lowering. This reduces strain on operators and enables smoother workflows.

Set and repeat lift heights, load release points, and paths. Great for assembly line applications or robotic integration.

Real-time monitoring of usage, cycle counts, and overload alerts can prevent downtime and improve preventative maintenance.

Smart hoists with digital load cells automatically detect and stop operation if unsafe conditions arise.

With features like collision avoidance, automatic slow-down zones, and remote operation, workers stay safer while handling heavy loads.

Automated controls reduce the margin of error during lifting and placing operations, minimizing product damage.

Reducing the time needed to manually position a load means faster cycle times and higher daily throughput.

Ergonomically optimized systems decrease physical strain on operators and reduce reliance on skilled manual labor.

While upfront costs for automation may seem high, the long-term savings in labor, maintenance, and downtime often justify the investment. Learn more in Why Jib Cranes Are a Cost-Effective Investment.

A small electronic components factory implemented a jib cranes solution using a wall-mounted, articulating jib with smart sensors and programmable lift heights. The result:

35% faster product transfer between assembly and packaging

70% reduction in minor handling errors

Less than 12-month ROI on total system upgrade

This type of setup is especially powerful in compact factories, where compact lifting solutions are essential.

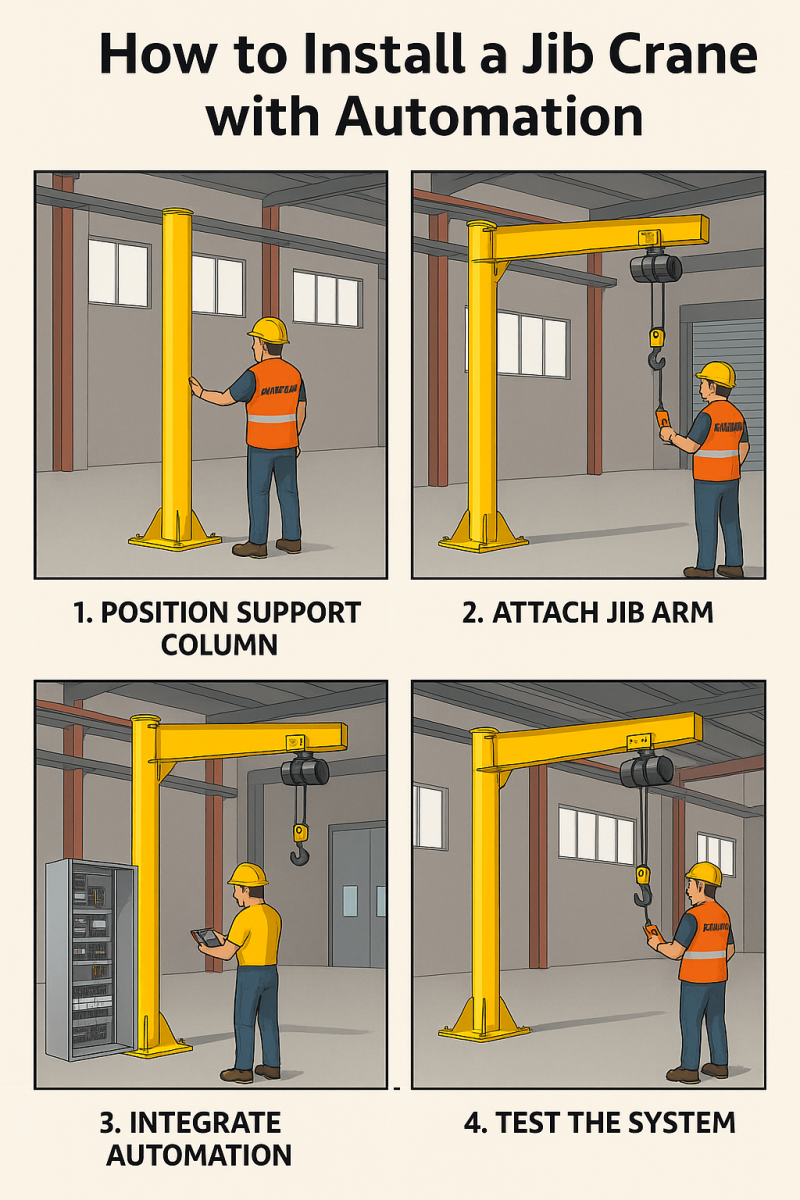

How to choose the right crane is just the first step. Implementing automation requires careful planning:

Assess Your Current Setup

What types of lifts are performed?

What are the most common bottlenecks?

Define Automation Goals

Is the goal higher throughput? Better safety? Lower staffing?

Choose the Right Crane Type

Match your workspace to the crane’s rotation range and capacity.

Select Smart Components

Motorized hoists, PLCs, load monitoring, remote panels, etc.

Train Staff and Operators

Ensure safety procedures and digital controls are understood.

Track Performance

Use data logs to improve further and justify ROI.

As AI and machine learning evolve, we can expect smarter systems with:

Predictive maintenance alerts

AI-based lift path optimization

Integration with AGVs and smart shelves

Augmented reality for crane training and diagnostics

Facilities that invest now will be better positioned for this next industrial wave.

Automation isn’t a luxury—it's a strategic move. For operations that rely on fast, accurate, and safe material handling, automated Jib Cranes offer an unmatched return on investment.

Whether you’re upgrading a freestanding jib crane with motorized features or installing a fully networked ceiling mounted crane, the benefits compound over time.

Ready to modernize your lifting operation? Begin your journey with a crane type that fits your space and explore how Jib cranes play an important role in your warehouse today.

References

1. How to operate a Jib Cranes safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.