In the world of stone fabrication, handling heavy and delicate materials—such as granite, marble, and engineered stone slabs—requires precision and care. Traditional methods like manual labor or mechanical clamps can lead to inefficiencies, safety risks, and potential damage to valuable slabs. A vacuum lifter provides a modern, efficient solution that not only boosts productivity but also safeguards each piece of stone.

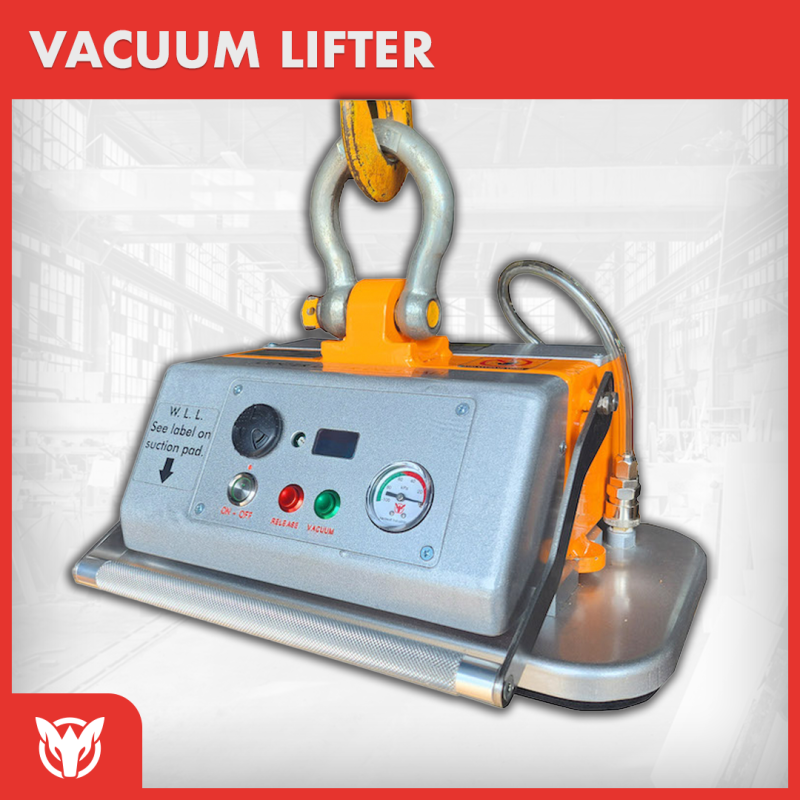

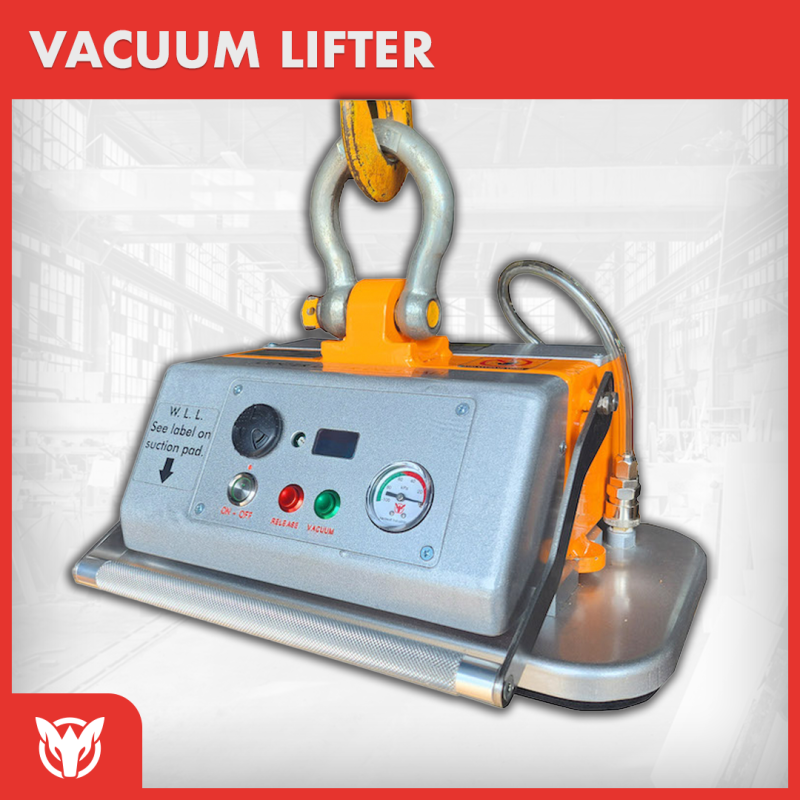

A vacuum lifter is a specialized material-handling device that uses suction technology to lift and transport heavy or fragile items, including stone slabs, glass, and metal sheets. Unlike traditional lifting methods relying on clamps or slings, vacuum lifters deliver a firm yet gentle grip via advanced suction. Models designed as stone vacuum lifters or granite vacuum lifters accommodate a wide range of finishes—from smooth and polished to rough surfaces.

Glossary Note:

WLL (Work Load Limit): The maximum load a lifter is designed to handle safely.

A slab vacuum lifter operates by creating negative pressure between the suction pad and the material’s surface, thanks to a high-performance vacuum pump. Below is an overview of the process:

To ensure optimal performance and safety in stone fabrication, follow these recommendations:

Q: What types of materials can a vacuum lifter handle?

A: Vacuum lifters are ideal for both heavy and delicate materials, including stone slabs, glass panels, and metal sheets.

Q: How often should I inspect my vacuum lifter?

A: Conduct a pre-use inspection before each operation and schedule routine maintenance as advised by the manufacturer.

Q: Can I use a vacuum lifter for irregularly shaped materials?

A: While vacuum lifters are generally designed for flat surfaces, certain models come with adaptable pads for slightly irregular shapes. Always consult the product manual for guidance.

Beyond enhancing safety and efficiency, vacuum lifters also support sustainability goals in stone fabrication:

In stone fabrication, a vacuum lifter is more than a convenient piece of equipment—it’s a transformative tool that streamlines operations, reduces damage, and promotes worker safety. By adhering to best practices and investing in a reliable slab vacuum lifter, fabricators can meet the rigorous demands of modern projects while also reaping long-term cost savings and sustainability benefits.

Disclaimer:

This article provides general information only and does not replace professional advice or local regulations. Always consult the product manual and follow all safety standards. Neither the author nor the publisher assumes liability for injuries, damages, or losses arising from use of this information. Use equipment at your own risk.

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.