From assembly lines and warehouses to workshops and outdoor loading bays, selecting the right jib crane ensures both productivity and safety.

Whether you're outfitting a new facility or upgrading old equipment, this guide explores how to evaluate, compare, and choose the best crane type for your specific material handling needs.

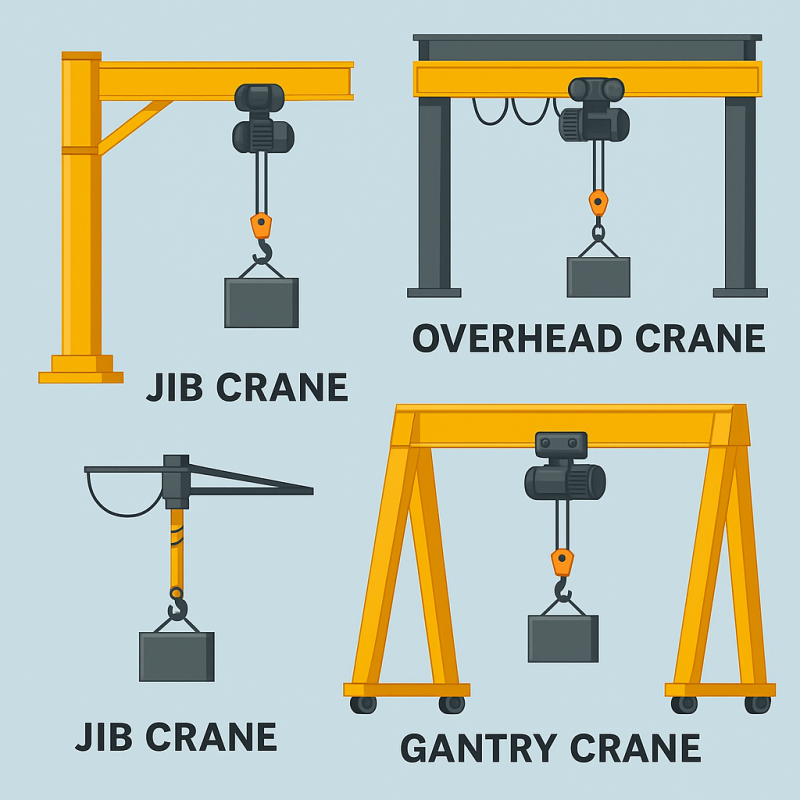

Jib Cranes are designed for localized lifting. Unlike gantry or overhead cranes that span wide areas, jib cranes provide targeted material movement in compact zones. This makes them perfect for repetitive tasks within a defined radius—especially where other cranes may be oversized or impractical.

See how to choose the ideal jib cranes for streamlined workflows.

A freestanding jib crane is mounted on the floor with a reinforced concrete foundation. It typically offers 360° rotation and is capable of handling heavy loads.

Best For: Open factory floors, maintenance areas, heavy machinery loading

Key Strengths: Full rotation, independent support, high capacity

The wall mounted jib crane is attached to a load-bearing wall or vertical support beam. It offers up to 200° of rotation and saves valuable floor space.

Best For: Workshops, loading bays, facilities with limited floor area

Key Strengths: Cost-effective, minimal footprint, high precision

This type is mounted directly onto overhead structural elements, eliminating the need for vertical support altogether.

Best For: Areas where floor space is at a premium

Key Strengths: Clears ground obstructions, integrates into tight areas

Articulating models feature a two-arm design with separate pivot points, allowing operators to navigate around machinery or obstructions.

Best For: Complex workstations with variable reach requirements

Key Strengths: Precision positioning, obstacle navigation

A pillar jib crane, often referred to as column-mounted, offers a stable vertical base for lifting. It’s often used in repetitive operations near assembly lines.

Best For: Fixed-position tasks, repetitive handling

Key Strengths: Long-lasting stability, dependable lifting radius

Want to learn more? Explore different types of jib cranes in more detail with performance insights and use cases.

Safety is paramount when lifting loads of any size. Modern smart jib cranes feature intelligent safety mechanisms:

Overload detection systems to prevent structural strain

Rotational limiters for controlled movement

Emergency stop controls accessible from remote pendants

Sensor-based obstacle detection for safe operation in shared workspaces

Discover why smart jib cranes feature intelligent safety compared to older crane technologies.

Determine the maximum load weight and frequency of lifts. Overestimating ensures safety and flexibility.

Evaluate whether your space allows for a freestanding structure or needs wall/ceiling mounting. Consider ceiling height, floor strength, and nearby obstructions.

Each type has different swing capabilities:

Freestanding: 360°

Wall/Ceiling Mounted: up to 200°

Articulating: customized reach in irregular zones

Some cranes are more complex to install. For instance, freestanding cranes require a foundation, while ceiling-mounted cranes demand structural analysis.

See the diverse ranges of jib crane to understand what installation suits your facility best.

Today’s smart jib cranes are more than mechanical arms—they're intelligent systems.

Automated lift/lower presets reduce operator workload

IoT integration enables performance tracking and diagnostics

Remote operation ensures safety in hazardous areas

Energy-efficient motors cut down on operational costs

Explore how the smart jib cranes utilize automation to streamline repetitive tasks and reduce errors.

Jib cranes are used to load raw materials into machines, assemble heavy components, and shift finished goods onto conveyors.

Wall-mounted and pillar jib cranes assist in staging, packing, and container loading where forklifts can’t operate efficiently.

Articulating jib cranes are used to maneuver engines, chassis parts, and tires into tight-fitting assembly locations.

Explore the potential of lifting solutions designed specifically for these complex operations.

Working with the right crane supplier means more than just delivery. Look for:

Customization options

After-sales support and training

Engineering consultations

Safety compliance assurance

Learn more in Choosing and Installing the Right Jib Crane to ensure you make an informed decision for long-term ROI.

Jib Cranes offer a smart, compact, and flexible material handling solution tailored for modern industrial operations. Whether it’s a freestanding, wall mounted, ceiling mounted, articulating, or pillar jib crane, there’s a solution that fits every layout and application.

For a full breakdown, visit Exploring Different Types of Smart Jib Cranes to start your selection journey with confidence.

1. How to operate a Jib Crane safely

3. Over brace jib crane wall mounted

5. Is a Jib Crane a Gantry Crane

6. Articulated Jib Crane Wall Mounted

8. Manual Counterbalance Crane

10. Over Braced Jib Crane Column Mounted

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.