Ratchet tie down straps are a popular solution for securing cargo in transportation and logistics. They are designed to apply tension gradually and securely around loads, preventing any unwanted movement during transit. The simplicity of their design combined with their robust functionality makes them an ideal choice across various industries.

In addition to their core function, ratchet tie down straps are also crucial components in material handling processes. They are used alongside other pieces of material handling equipment such as forklifts and pallet jacks to ensure that goods are moved safely and efficiently. For a closer look at the significance of these practices, visit material handling.

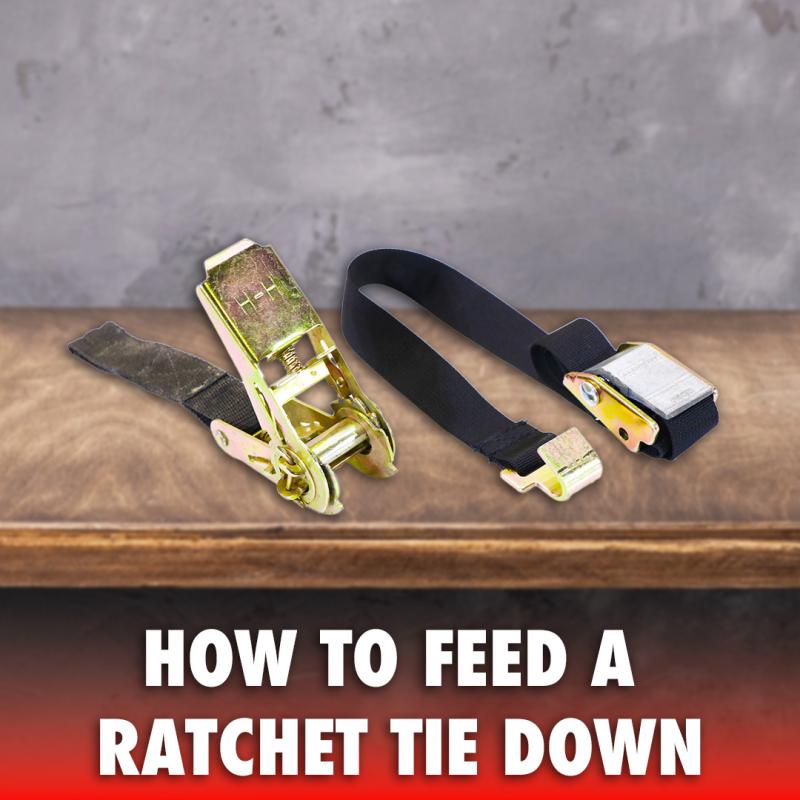

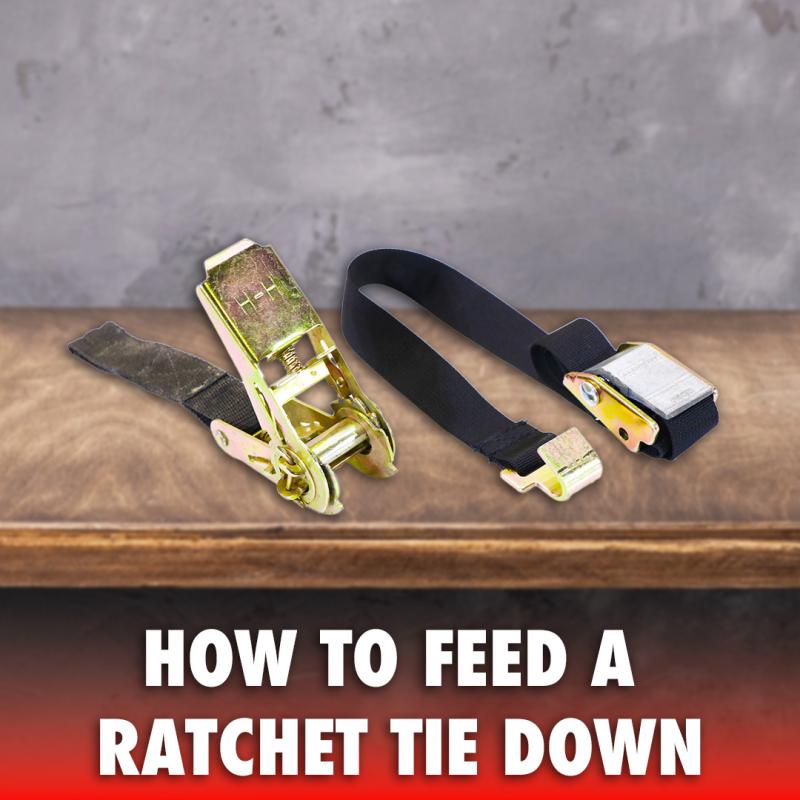

At their core, ratchet tie down straps are engineered devices used to secure cargo through a mechanical ratchet mechanism. The design allows users to tighten the strap incrementally, locking it in place and ensuring that the load remains immobile.

The Ratchet Mechanism: This component is the heart of the tie down strap, enabling the gradual increase in tension as you crank the handle.

The Webbing: Typically crafted from durable polyester or nylon, the webbing is the flexible component that wraps around the load.

Hooks or Buckles: These are used to attach the strap securely to the cargo or fixed anchor points.

Release Catch: A critical safety feature that allows you to quickly disengage the ratchet mechanism when it’s time to remove or adjust the strap.

Each component is designed to work in unison to ensure that the load remains secure under various conditions.

Feeding a ratchet tie down refers to the process of threading the webbing through the ratchet mechanism before tensioning the strap. This step is essential for ensuring that the strap engages correctly with the ratchet, providing the necessary leverage to tighten the load securely.

Before tensioning a ratchet tie down strap, it is crucial to ensure that the webbing is fed properly. This step ensures that the strap will grip evenly and maintain consistent tension. If the webbing is not fed correctly, it can lead to uneven pressure distribution, which may compromise load security and lead to potential hazards during transport.

Begin by laying out your ratchet tie down straps on a flat surface. Inspect the strap for any signs of wear or damage. A visual check of the webbing and ratchet mechanism helps to ensure that you are working with a functional piece of equipment.

Tip: Always make sure that the strap is clean and free of debris. A clean strap feeds more smoothly through the mechanism.

Before feeding the webbing, unlock the ratchet mechanism using the release catch. This disengages the locking system, allowing you to insert the webbing into the correct channel.

Tip: Look for the release catch on the side of the ratchet and gently pull it open to unlock the mechanism.

With the mechanism unlocked, insert the end of the webbing into the designated slot at the bottom of the ratchet. Carefully guide the webbing through until it emerges from the other side. This process ensures that the webbing is threaded evenly throughout the ratchet’s internal components.

Tip: If you experience any resistance, check that the webbing is not twisted or caught on any internal parts. A smooth feed is crucial for optimal performance.

Once the webbing is threaded, pull the excess material through until it is taut but not overly tight. This step prepares the strap for the tensioning process. The webbing should be straight and free of slack, ensuring an even application of tension when you start cranking the ratchet.

After feeding the webbing and ensuring it is properly aligned, start cranking the ratchet handle. As you turn the handle, the mechanism will gradually pull the webbing tighter around your load. Continue this process until the strap is securely fastened.

Tip: Avoid over-tensioning the strap. While it is important to eliminate slack, too much tension can damage the cargo or the strap itself.

Once you have reached the desired level of tension, secure the ratchet in its locked position. This prevents the strap from loosening during transit. The locking mechanism should engage automatically once the correct tension is achieved. Double-check to ensure that the strap remains firmly in place.

When it’s time to remove the strap, engage the release catch once again to unlock the mechanism. Slowly release the tension, ensuring that the load remains stable throughout the process. Once the strap is loosened, carefully remove the webbing from the ratchet.

For a detailed visual guide and more in-depth instructions, explore this resource on how to use ratchet tie down straps.

Ratchet tie down straps are not only essential for securing loads but also play a pivotal role in overall material handling practices. They are often used in conjunction with other material handling equipment to ensure that goods are transported safely and efficiently.

In warehouses, logistics hubs, and construction sites, ratchet tie down straps are a fundamental part of the cargo management process. They work alongside forklifts, pallet jacks, and conveyor systems to secure loads during movement and storage. This integration helps prevent accidents and improves operational efficiency.

Using high-quality ratchet tie down straps ensures that the load is firmly secured, reducing the risk of damage during transit. The reliability of these straps makes them a favorite among professionals in the transportation and logistics industries.

Enhanced Safety: Properly fed and tensioned straps prevent load shifting, which is crucial for avoiding accidents during transport.

Efficient Cargo Securing: A well-fed strap allows for even tension distribution, making the securing process more efficient and reliable.

Extended Strap Lifespan: Correct usage and maintenance, including proper feeding, can significantly extend the lifespan of your straps, offering long-term cost savings.

Even with the best equipment, users might encounter some common challenges when feeding a ratchet tie down. Here are some troubleshooting tips to help you overcome these issues.

If you notice that the webbing is not sliding through the ratchet easily, inspect the strap for twists or kinks. Sometimes, the webbing may become misaligned within the mechanism, causing resistance.

Tip: Unthread the strap and start the feeding process again, ensuring that the webbing is completely straight and free of obstructions.

Inconsistent tensioning can occur if the webbing is not fed evenly or if there is a defect in the ratchet mechanism. This may result in a loose or unevenly secured load.

Tip: Check that the webbing is properly aligned within the ratchet before applying tension. If the problem persists, consider testing another strap to determine if the issue lies with the specific piece of equipment.

If the ratchet fails to lock properly after tensioning, there may be debris or wear within the mechanism. Regular maintenance and cleaning are key to preventing such issues.

Tip: Clean the ratchet mechanism periodically using a soft brush and mild cleaning solution. Lubricate moving parts according to the manufacturer’s recommendations to ensure smooth operation.

Proper maintenance of your ratchet tie down straps is crucial for ensuring their long-term functionality and safety. Regular inspections and cleaning routines can prevent wear and tear, keeping your equipment in top condition.

Routine Cleaning: After each use, wipe down the straps with a damp cloth to remove dirt and debris.

Deep Cleaning: For more thorough cleaning, use a mild detergent solution and allow the straps to air dry completely before storage.

Cool and Dry Environment: Store straps in a cool, dry place away from direct sunlight, as prolonged exposure can degrade the materials.

Avoid Heavy Loads: Do not stack heavy objects on top of stored straps, as this may cause deformation or damage.

Before each use, inspect the straps for any signs of damage such as fraying, cuts, or worn-out components. Replacing compromised straps immediately is essential to maintaining load safety and operational efficiency.

Proper training is essential for anyone using ratchet tie down straps. Whether you work in logistics, construction, or any field that involves securing cargo, understanding the correct feeding and tensioning techniques is key.

Regular training ensures that all team members are familiar with the proper procedures for feeding and securing straps. This not only enhances safety but also boosts overall productivity by reducing the risk of improper usage.

Always refer to the manufacturer’s instructions for detailed guidelines on how to feed and use your specific ratchet tie down straps. These instructions are designed to maximize both performance and safety.

Keep a record of any issues or challenges encountered during the feeding process and share solutions with your team. Staying informed about best practices and any updates in technology can lead to better outcomes in the long run.

As the fields of material handling and transportation continue to evolve, so too does the technology behind cargo securing. Innovations in ratchet tie down design are continually emerging, aimed at improving ease of use, durability, and safety.

One emerging trend is the integration of smart sensors into ratchet tie down straps. These sensors can monitor tension in real time, alerting users to any deviations from optimal settings. Such advancements promise to reduce accidents and improve overall load security.

Advances in material science are also leading to the development of stronger, more durable webbing materials. These innovations not only extend the life of the straps but also offer enhanced resistance to environmental factors, such as UV exposure and extreme temperatures.

Future designs may also incorporate more intuitive user interfaces, making it even easier to feed the strap properly and apply the correct tension. This evolution in design will further contribute to safer and more efficient cargo handling practices.

Feeding a ratchet tie down correctly is a fundamental skill that underpins the safety and efficiency of cargo securing. By understanding the components, following a step-by-step feeding process, and adhering to regular maintenance and safety protocols, you ensure that your ratchet tie down straps perform optimally every time.

From the initial step of preparing and inspecting the strap to engaging the ratchet mechanism and ultimately tensioning and locking it in place, every stage of the process plays a critical role in ensuring load stability. Whether you’re working in heavy-duty material handling environments or handling personal cargo, the principles discussed in this guide are applicable across a wide range of scenarios.

For those interested in learning more about securing loads effectively, check out this comprehensive guide on how to use ratchet tie down straps. Additionally, if you’re looking for high-quality products, explore our range of ratchet tie down straps to find the perfect solution for your needs.

By embracing proper feeding techniques, regular maintenance, and ongoing training, you not only enhance the safety of your operations but also contribute to a more efficient and reliable cargo transport system. As technology evolves and new trends emerge, the fundamental importance of correctly feeding and securing ratchet tie down straps will remain a cornerstone of safe cargo handling practices.

Whether you’re a seasoned professional or new to the field, mastering the art of feeding a ratchet tie down is a vital skill that ensures the longevity of your equipment and the safety of your cargo. Embrace these best practices, stay informed about technological advancements, and always prioritize safety in every operation.

Ultimately, the simple act of feeding a ratchet tie down correctly has far-reaching benefits—from protecting valuable assets to streamlining your material handling processes. In an industry where every detail counts, ensuring that your cargo is secured with precision is not just a best practice; it’s an essential component of operational excellence.

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.