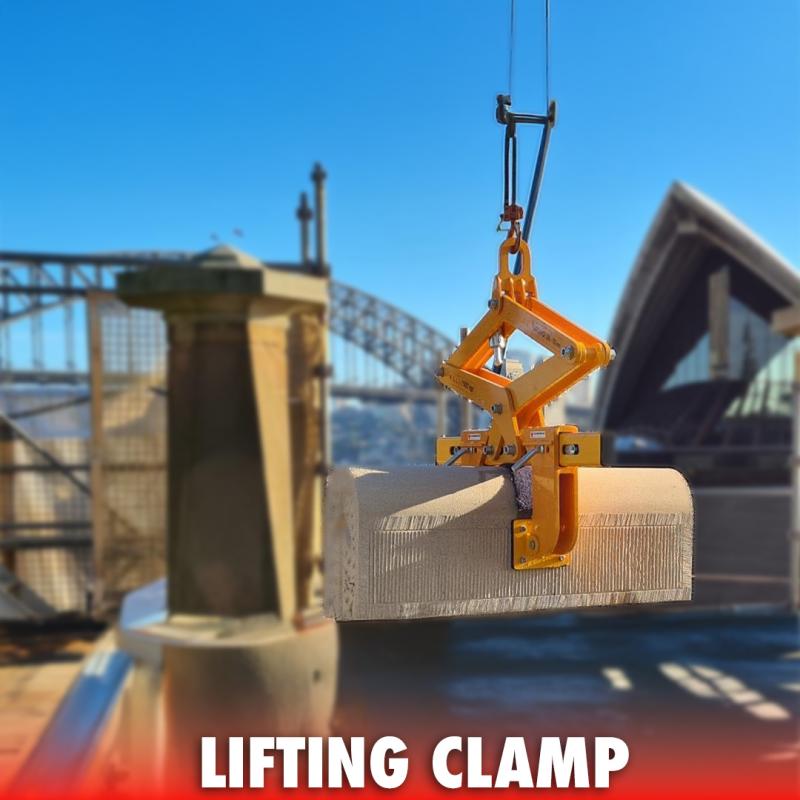

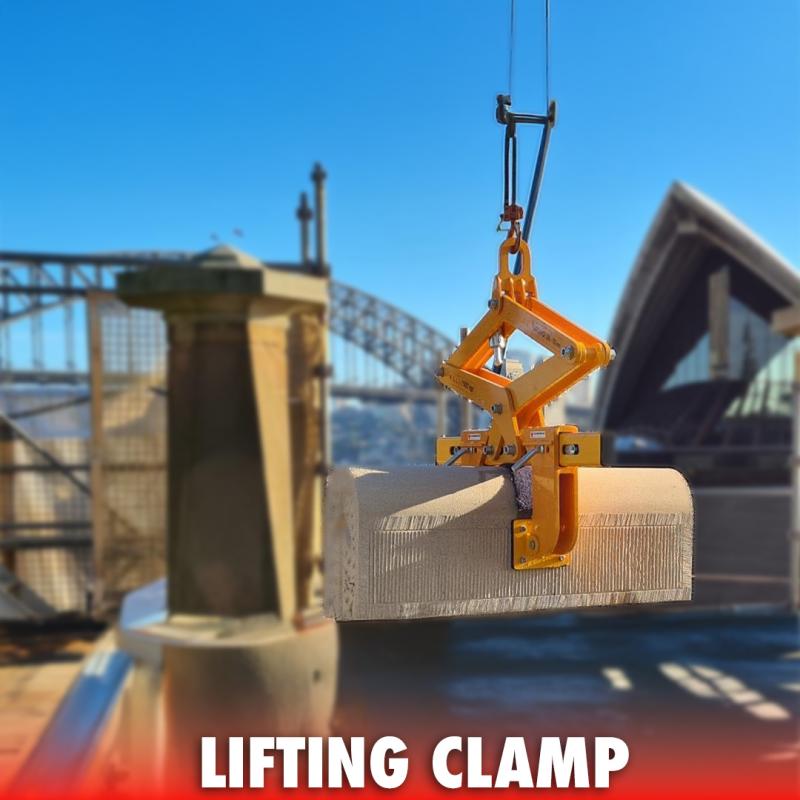

Lifting clamps are mechanical tools specifically designed for grasping and lifting heavy objects such as steel plates, concrete slabs, pipes, and other cumbersome loads. They securely grip the material, enabling safe lifting, transportation, and positioning, significantly reducing manual labor and potential injuries.

Choosing the correct type of lifting clamp depends on various factors including load type, weight, surface conditions, and intended application. Incorrect selection can lead to accidents, material damage, and downtime.

Lifting plate clamps are specifically engineered for handling flat sheet metal and steel plates. These clamps utilize a powerful gripping mechanism, typically using friction or pressure to maintain hold. Plate clamps can be vertical or horizontal, designed for various lifting orientations.

Vertical plate clamps securely lift plates from a horizontal to a vertical position, ideal for placing materials onto cutting tables or loading onto transportation vehicles.

Horizontal lifting plate clamps are designed to handle plates that remain in a horizontal orientation during transport, perfect for stacking or moving materials across a facility.

Scissor lifters, often known as scissor clamps, are another type of specialized lifting clamp frequently used for handling slabs or heavy sheets. They operate with a scissor mechanism that tightens as it lifts, providing excellent security and stability.

For example, a high-quality scissor lifter from Aardwolf is specially designed to lift heavy slabs efficiently, safely, and effectively, greatly optimizing productivity.

Beam clamps are designed for attaching lifting equipment to structural steel beams. They provide a secure anchor point for hoists, chains, or ropes, and are frequently used in construction or industrial environments.

Pipe lifting clamps specifically accommodate cylindrical materials such as pipes or tubes. Their design ensures the secure grip of rounded surfaces without slippage, enhancing safe transport and handling.

Drum clamps safely lift and transport drums or barrels containing liquids or solids. These clamps securely hold drums vertically or horizontally, minimizing the risk of spills and accidents.

Girder clamps are utilized for lifting heavy steel girders. They provide a secure grip on flanged beams or girders and are essential for various structural engineering and construction tasks.

Screw clamps are adjustable clamps that use threaded screws to tighten and secure the grip on heavy loads. They are versatile and widely applicable for different lifting scenarios.

Each lifting clamp has a specified maximum load capacity. Exceeding this capacity can result in clamp failure and severe safety hazards. Always verify the load rating before selecting a clamp.

Material surface condition significantly affects the grip of lifting clamps. Smooth, oily, rough, or textured surfaces require different clamp designs for effective handling.

Consider the intended application—vertical lifting, horizontal transport, or specialized positioning—when selecting clamps. Using the appropriate clamp ensures efficiency and safety.

Using the appropriate lifting clamp minimizes the risks associated with manual handling, reducing workplace injuries and promoting a safer working environment.

Efficient material handling equipment speeds up processes, improving productivity and operational workflow. Using high-quality material handling equipment significantly boosts efficiency.

Proper lifting clamps ensure materials are securely handled, reducing the risk of dropping or damaging loads, thus avoiding costly material losses.

Lifting clamps find extensive applications across various industries:

Construction: Handling steel girders, concrete slabs, beams, and prefabricated building materials.

Manufacturing: Moving sheets, pipes, and metal components during fabrication processes.

Shipping and Logistics: Loading and unloading cargo, containers, and large industrial goods safely.

Warehousing: Organizing storage, retrieval, and transportation of bulky and heavy items.

Selecting high-quality lifting clamps from reputable manufacturers like Aardwolf ensures reliability, durability, and safety compliance. Quality equipment undergoes stringent testing and adheres to industry standards, significantly enhancing performance.

Routine inspection and maintenance are crucial for ensuring the longevity and safety of lifting clamps:

Regularly check for wear and damage.

Keep clamps clean and lubricated.

Store lifting clamps properly to avoid corrosion and deterioration.

Replace damaged components immediately.

Understanding the different types of lifting clamps, including lifting plate clamps, scissor lifters, and specialized clamps, is critical to optimizing safety and efficiency in material handling operations. By carefully considering load capacities, surface conditions, and applications, industries can significantly enhance their operational performance. Always invest in high-quality lifting equipment and adhere to maintenance protocols to ensure long-lasting functionality and safe operations.

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.