When it comes to heavy lifting, the boom forklift is an unsung hero of industrial operations. These versatile attachments transform forklifts into powerful lifting machines, making material handling faster, safer, and more efficient. But with great power comes great responsibility—using a telescopic forklift boom improperly can lead to accidents, equipment damage, and costly downtime.

This guide explores the advantages of forklift boom attachments, the differences between fixed and telescopic forklift booms, and the common mistakes to avoid when using them.

❌ Overloading the Forklift Boom

Exceeding the weight limit is one of the most dangerous mistakes, leading to equipment failure, instability, and accidents.

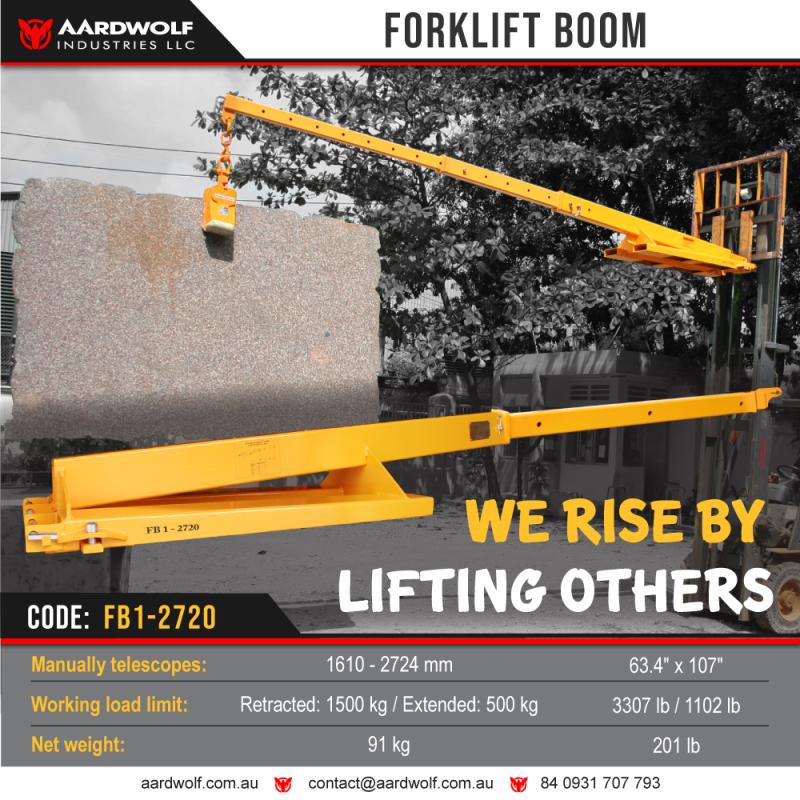

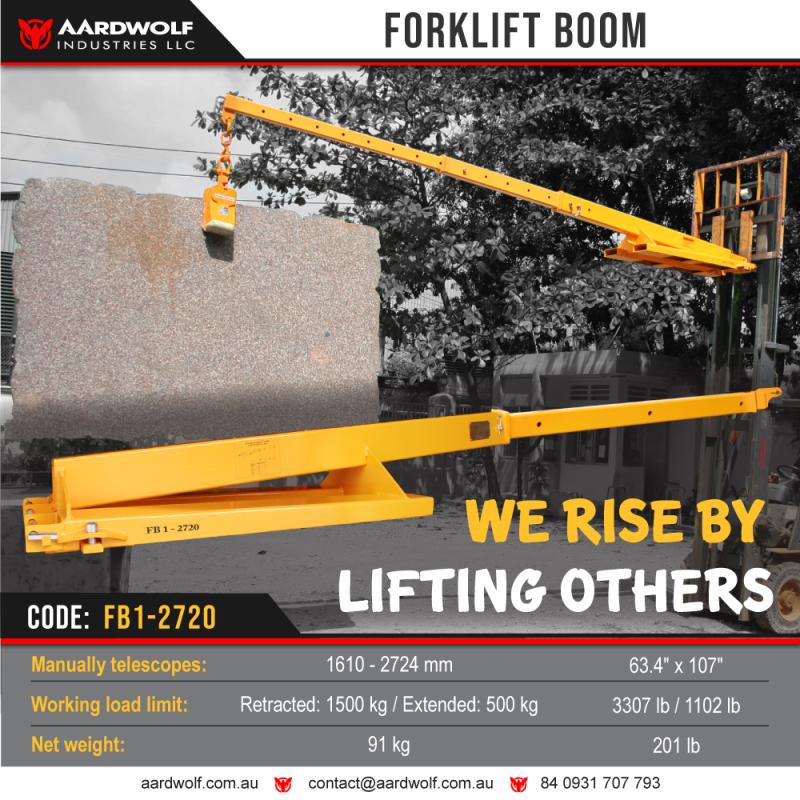

✅ Solution: Always check the manufacturer’s specified weight capacity. For example, the Aardwolf FB1-2720 supports up to 1,500 kg when retracted and 500 kg when fully extended, ensuring stability when used correctly. For heavy-duty tasks, a hydraulic forklift boom offers greater control and balance.

❌ Improper Attachment

A loose or poorly secured forklift boom attachment can cause detachment, load shifts, and operational hazards.

✅ Solution: Secure the boom with locking bolts and restraint pins before every use. The Aardwolf FB1-2720 features a firm two-bolt locking mechanism and fork carriage attachment for enhanced safety. If you require long reach forklift boom capabilities, ensure the attachment is properly locked before extending.

❌ Ignoring Safety Guidelines

Neglecting essential safety protocols like wearing PPE, ensuring load stability, or skipping pre-use inspections can put lives at risk.

✅ Solution: Implement regular safety training and follow manufacturer-recommended guidelines. The Aardwolf FB1-2720 manual advises always tilting the fork mast back and avoiding standing under a lifted load. The forklift telescopic attachment requires special handling, making operator training crucial.

❌ Choosing the Wrong Boom Forklift

Not all forklift booms are created equal! Using a fixed boom when you need an extendable forklift boom can limit reach and efficiency.

✅ Solution: Select the right tool for the job. The Aardwolf FB1-2720 is designed with telescoping capabilities that allow for adjustable lifting distances, making it perfect for specialized applications. For industries requiring precision and flexibility, a variable reach forklift boom is a great alternative.

❌ Skipping Maintenance

A poorly maintained boom forklift leads to malfunctions, costly repairs, and reduced lifespan.

✅ Solution: Regularly inspect moving parts, lubricate extension tubes, and check for wear. The Aardwolf FB1-2720 manual stresses frequent checks of locking pins, bolts, welds, and fork carriage attachments to ensure peak performance.

When choosing a forklift boom, businesses must decide between two primary types: fixed forklift booms and telescopic forklift booms. Each type offers unique advantages, making them suitable for different applications.

A fixed forklift boom is a rigid attachment that extends the reach of a forklift without adjustable length capabilities. It is designed for consistent and predictable lifting tasks where a set boom length is sufficient.

Advantages:

Disadvantages:

Best Use Cases:

A telescopic forklift boom is an adjustable attachment that allows for variable boom lengths, providing enhanced flexibility and reach.

Advantages:

Disadvantages:

Best Use Cases:

Forget standard forklift limitations—telescopic forklift booms extend beyond traditional reach, making high and hard-to-reach lifts easy.

Best for: Warehouses, construction sites, and logistics hubs needing extra height & distance.

Weight distribution is everything! A long-reach forklift boom prevents shifting or dropping loads, improving balance and safety.

Best for: Moving steel beams, concrete slabs, and industrial pipes securely.

Less manual handling = fewer workplace injuries. A hydraulic forklift boom improves safety by reducing operator fatigue and enhancing load control.

Best for: Reducing reliance on cranes and extra labor.

4. Cost-Effective Lifting Solution

Save money by cutting down on extra lifting equipment while boosting efficiency.

Best for: Companies aiming to streamline operations & reduce overhead costs.

5. Industry-Wide Adaptability

Forklift telescopic attachments thrive in diverse industries:

A boom forklift is a must-have for efficient material handling, but proper usage and maintenance are key to maximizing its benefits. Avoiding common mistakes like overloading, improper attachment, and neglecting safety measures can extend equipment lifespan and prevent costly workplace accidents.

Investing in a telescopic forklift boom means enhanced reach, stability, and efficiency—making it the go-to choice for heavy lifting across industries.

Ready to take your forklift performance to the next level? Choose a long-reach forklift boom and lift smarter!

Sign up to receive the latest info on new Aardwolf products, special offers and more.

By signing up you agree to receive emails from Aardwolf with news, special offers, promotions and other information. You can unsubscribe at any time.