Lifting Clamps vs. Traditional Heavy-duty-lifting Methods: A Comparison

In the construction and stone fabrication industries, material handling plays a critical role in ensuring operational efficiency, safety, and cost-effectiveness. Among the various methods available for handling heavy materials like stone slabs, beams, and pipes, lifting clamps have emerged as a preferred tool for modern industries. However, traditional stone handling methods, including manual labor, slings, and forklifts, remain in use. This article provides a comprehensive comparison of lifting clamps and traditional stone handling methods, exploring their advantages, limitations, and applications.

In the construction and stone fabrication industries, material handling plays a critical role in ensuring operational efficiency, safety, and cost-effectiveness. Among the various methods available for handling heavy materials like stone slabs, beams, and pipes, lifting clamps have emerged as a preferred tool for modern industries. However, traditional stone handling methods, including manual labor, slings, and forklifts, remain in use.

This article provides a comprehensive comparison of lifting clamps and traditional stone handling methods, exploring their advantages, limitations, and applications.

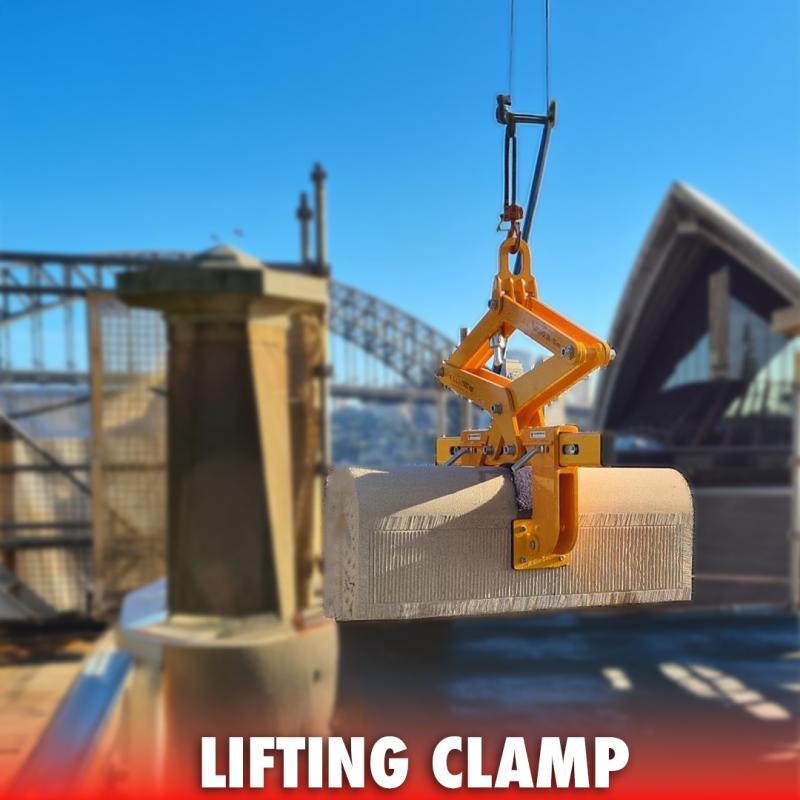

What Are Lifting Clamps?

Lifting clamps are specialized tools designed to securely grip and lift heavy materials, allowing for precise handling with minimal effort. They come in various types tailored to specific needs.

These tools are engineered to enhance safety, efficiency, and versatility in material handling, making them a staple in industries that deal with heavy materials.

Lifting clamps are mechanical devices that grip, lift, and move objects horizontally or vertically. They are used in many industries, including construction, manufacturing, and shipbuilding.

Traditional Stone Handling Methods

Lifting clamps are mechanical tools designed to securely grip and lift heavy or delicate materials, enabling efficient handling with minimal effort. Tailored for various applications, they are widely used in industries such as construction, manufacturing, and stone fabrication. These clamps ensure safe and precise material handling, whether in horizontal or vertical orientations, making them essential for reliable and damage-free operations.

Comparative Analysis: Lifting Clamps vs. Traditional Methods

1. Safety

- Lifting Clamps: Modern lifting clamps come equipped with advanced safety features, such as secure gripping mechanisms, load monitoring systems, and locking levers. These features minimize accidents and reduce the need for manual intervention, lowering the risk of worker injuries.

- Traditional Methods: Manual handling, slings, and forklifts can pose significant safety risks. Improper use of slings or unsecured loads often leads to accidents like dropped materials or worker injuries.

2. Efficiency

- Lifting Clamps: These devices streamline the lifting process by offering quick attachment and release, reducing downtime and increasing productivity. Their precision ensures materials are handled and positioned accurately, saving time.

- Traditional Methods: Traditional methods require more time to set up and often involve multiple workers, making the process slower and less efficient.

3. Versatility

- Lifting Clamps: Available in a variety of designs, lifting clamps can handle diverse materials, including flat slabs, cylindrical pipes, and even delicate glass panels. This makes them suitable for multiple industries, from construction to manufacturing.

- Traditional Methods: Slings and forklifts lack the adaptability required for handling materials of varying shapes and sizes, limiting their application.

4. Material Protection

- Lifting Clamps: Engineered with non-marring pads and adjustable jaws, lifting clamps provide a secure grip without damaging the surface of materials, making them ideal for handling polished or delicate stones.

- Traditional Methods: Slings and manual handling often result in scratches, chips, or other surface damages, compromising material quality.

5. Cost Implications

- Lifting Clamps: While they require a higher upfront investment, lifting clamps deliver long-term cost savings by reducing labor costs, minimizing material damage, and enhancing operational efficiency.

- Traditional Methods: Although cheaper initially, traditional methods incur higher long-term costs due to labor demands, frequent material damage, and slower operations.

Top Most Popular Lifting Clamps

Here are some of the most popular types of lifting clamps widely used in industries:

1. Slab Lifters

Slab lifters are designed to handle thin sheets of stone, engineered porcelain, and ceramic materials with precision and care.

- Applications: Transporting and positioning stone slabs, porcelain panels, and ceramic tiles for fabrication, polishing, or installation.

- Key Industries: Stone fabrication, architectural design, tile manufacturing, and construction.

2. Horizontal Stone Lifting Clamps

Horizontal stone lifting clamps are specifically designed to handle and maneuver concrete blocks and natural stones in a horizontal orientation.

- Applications: Moving large stone blocks or tiles horizontally for precise placement in construction or landscaping projects.

- Key Industries: Landscaping, stone fabrication, and masonry construction.

3. Pipe Lifting Clamps

Pipe lifting clamps specialize in securely gripping and lifting cylindrical materials such as pipes, tubes, and poles.

- Applications: Lifting and installing pipelines, transporting structural tubing, and maneuvering poles for infrastructure projects.

- Key Industries: Oil and gas, plumbing, and civil engineering.

4. Scissor Lifting Clamps

Scissor lifting clamps are versatile tools ideal for lifting marble and granite slabs, tombstones, concrete barriers, curbs, and median walls.

- Applications: Efficiently handling irregularly shaped materials such as concrete blocks, large stones, or granite slabs.

- Key Industries: Construction, landscaping, and urban development.

5. Drum Lifting Clamps

Drum lifting clamps are designed to securely grip and lift barrels, drums, and other cylindrical containers.

- Applications: Transporting and pouring chemicals, oils, and liquids stored in sealed drums.

- Key Industries: Chemical processing, food and beverage production, and warehousing.

Choosing the Right Lifting Clamp

Selecting the right lifting clamp depends on several factors:

- Material Type: Ensure compatibility with stone, steel, metal, or glass, etc.

- Weight Capacity: Match the clamp's capacity with the load.

- Grip Mechanism: Opt for clamps with secure, non-damaging grips.

- Application Environment: Consider indoor, outdoor, or quarry-specific requirements.

Investing in the right lifting clamp ensures operational efficiency, safety, and material protection.

Transform Your Workflow: Switch to Lifting Clamps

The comparison between lifting clamps and traditional stone handling methods highlights the clear advantages of lifting clamps in terms of safety, efficiency, versatility, and cost-effectiveness. While traditional methods may still have niche applications, the adoption of lifting clamps aligns with modern industry demands for productivity and worker safety.

For professionals in construction and stone fabrication, embracing lifting clamps is a forward-thinking move that enhances operations and ensures the integrity of materials. By choosing the right tools, businesses can stay ahead in competitive industries and achieve greater operational success.

Follow us on: