Phân loại

-

THIẾT BỊ NÂNG (146)

![THIẾT BỊ NÂNG]()

-

Thiết bị kẹp đá Aardwolf (18)

![Thiết bị kẹp đá Aardwolf]()

-

Thiết bị kẹp đá kiểu kéo (21)

![Thiết bị kẹp đá kiểu kéo]()

-

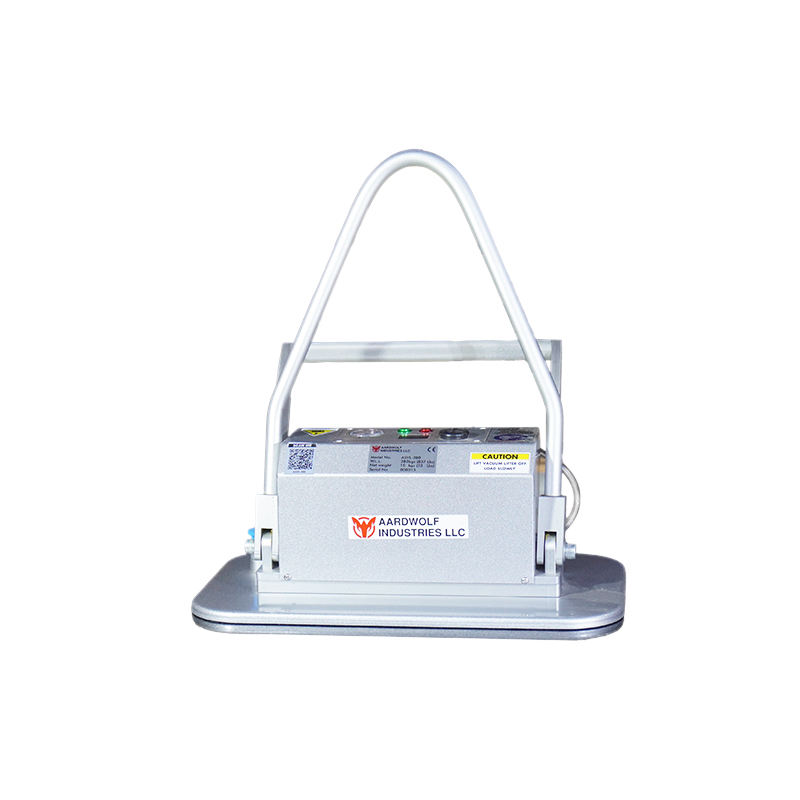

Thiết bị nâng chân không (49)

![Thiết bị nâng chân không]()

-

Thiết bị nâng chân không dạng ống (3)

![Thiết bị nâng chân không dạng ống]()

-

Thiết bị gắp thùng carton (1)

![Thiết bị gắp thùng carton]()

-

Thiết bị gắp thùng phuy (1)

![Thiết bị gắp thùng phuy]()

-

Thiết bị gắp bao (1)

![Thiết bị gắp bao]()

-

Thiết bị gắp đá tảng (3)

![Thiết bị gắp đá tảng]()

-

Thiết bị gắp gạch (1)

![Thiết bị gắp gạch]()

-

Thiết bị gắp ống tròn (6)

![Thiết bị gắp ống tròn]()

-

Thiết bị kẹp kính (3)

![Thiết bị kẹp kính]()

-

Xà ngang phân phối (4)

![Xà ngang phân phối]()

-

Thiết bị nâng hạ kiện đá (3)

![Thiết bị nâng hạ kiện đá]()

-

Thiết bị kẹp đá bằng tay (6)

![Thiết bị kẹp đá bằng tay]()

-

Tay nắm hút chân không (5)

![Tay nắm hút chân không]()

-

Sản phẩm khác (6)

![Sản phẩm khác]()

-

Thiết bị kẹp đá Aardwolf (18)

-

CẦN TRỤC XOAY (16)

![CẦN TRỤC XOAY]()

-

THIẾT BỊ BỔ TRỢ XE NÂNG (29)

![THIẾT BỊ BỔ TRỢ XE NÂNG]()

-

HỆ THỐNG LƯU TRỮ ĐÁ (28)

![HỆ THỐNG LƯU TRỮ ĐÁ]()

-

KHUNG CHỮ A (49)

![KHUNG CHỮ A]()

-

XE ĐẨY TAY (18)

![XE ĐẨY TAY]()

-

BÀN VÀ KHUNG GIA CÔNG (31)

![BÀN VÀ KHUNG GIA CÔNG]()

-

DỤNG CỤ LÀM VIỆC TRONG NHÀ MÁY (62)

![DỤNG CỤ LÀM VIỆC TRONG NHÀ MÁY]()

-

Đồ bảo hộ (17)

![Đồ bảo hộ]()

Sản Phẩm Nổi Bật

Follow us on: